Plate stamping type moving sidewalk pedal supporting seat

A moving walk, stamping technology, applied in escalators, transportation and packaging, etc., can solve the problems of high manufacturing cost, high cost, weight reduction of pedals, etc., to save operating costs and maintenance costs, good product consistency, manufacturing low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The substantive features of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

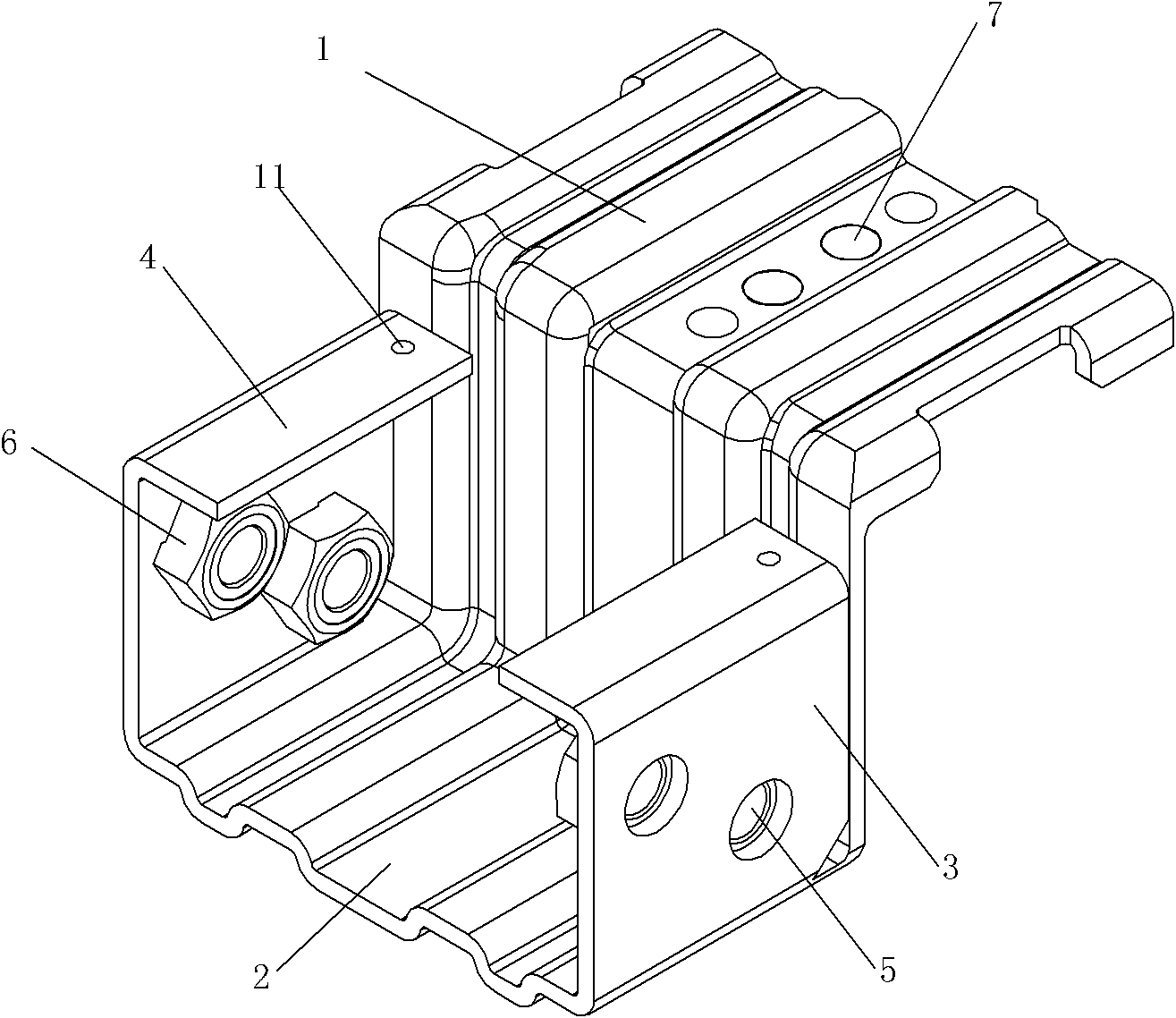

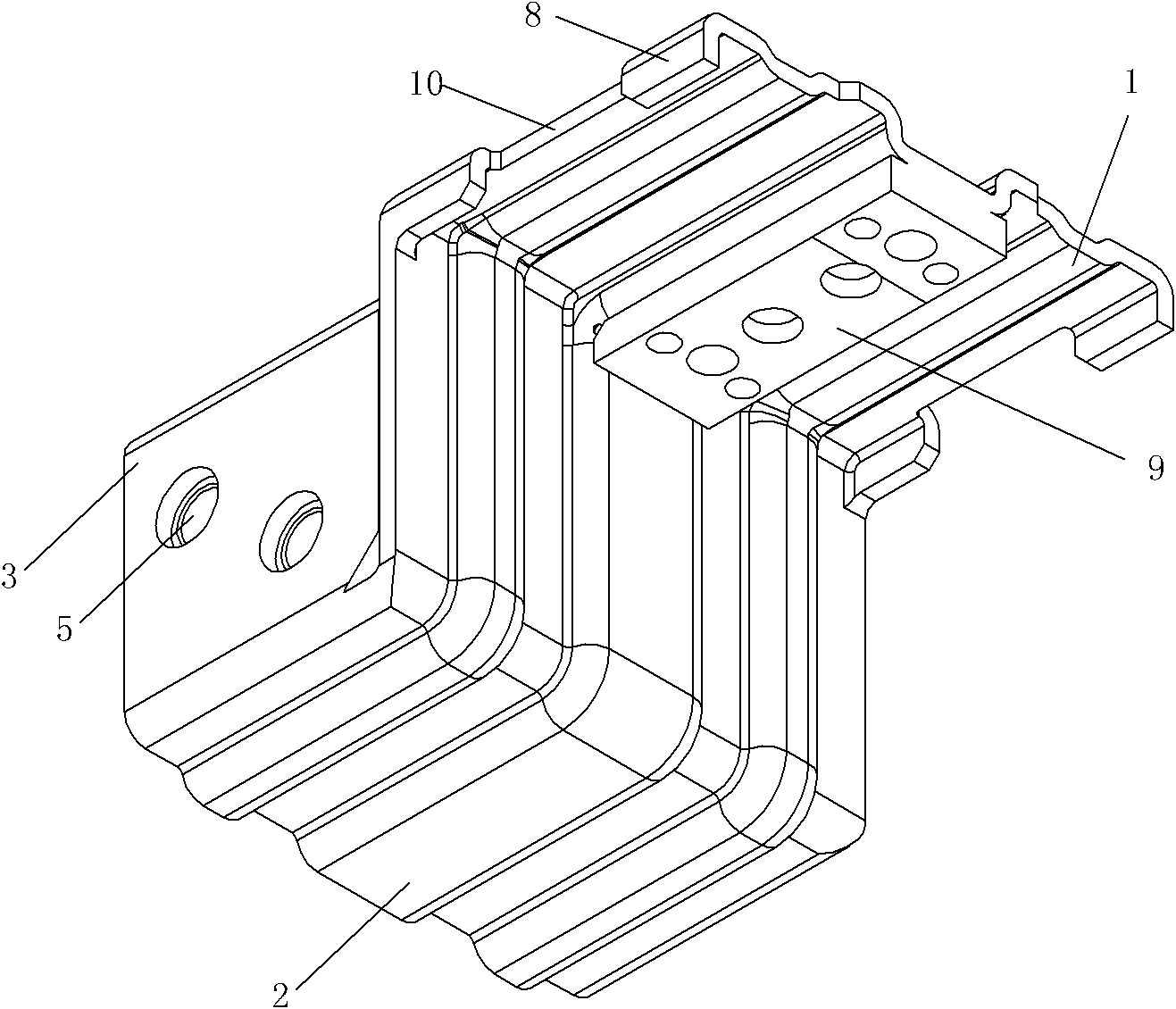

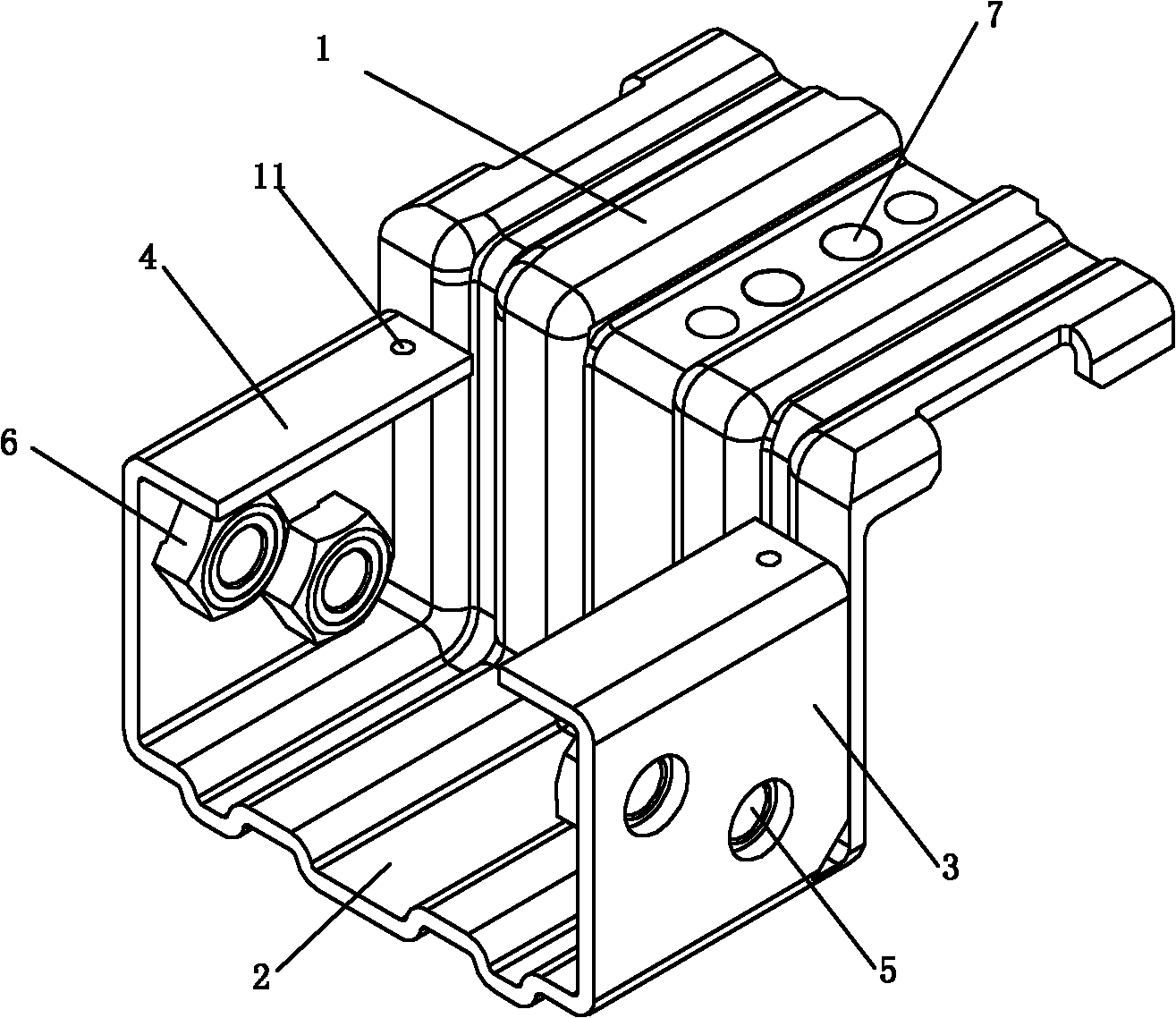

[0020] Such as Figure 1-2 As shown, for the sheet metal stamping type moving walk pedal support seat, a metal sheet with a thickness of 2.5-6 mm is selected to punch out a plurality of ribs, and then the metal sheet is sequentially bent out of the upper installation surface 1, the vertical surface and the lower installation surface 2 to form Stepped seat. The protruding ribs protrude toward the front and back sides of the metal plate and are arranged at intervals. A group of parallel edges of the upper mounting surface are symmetrically provided with bayonet sockets 10 and positioning teeth 8 . A reinforcing plate 9 is fixedly welded on the opposite side of the upper mounting surface. The upper mounting surface has two parallel ribs, and pedal mounting holes 7 are arranged between the ribs. The pedal mounting ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com