Non-isolated AC-DC (Alternating Current-Direct Current) LED driver current compensation circuit

A current compensation circuit, non-isolated technology, applied in the direction of lamp circuit layout, electric light source, irreversible AC power input conversion to DC power output, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

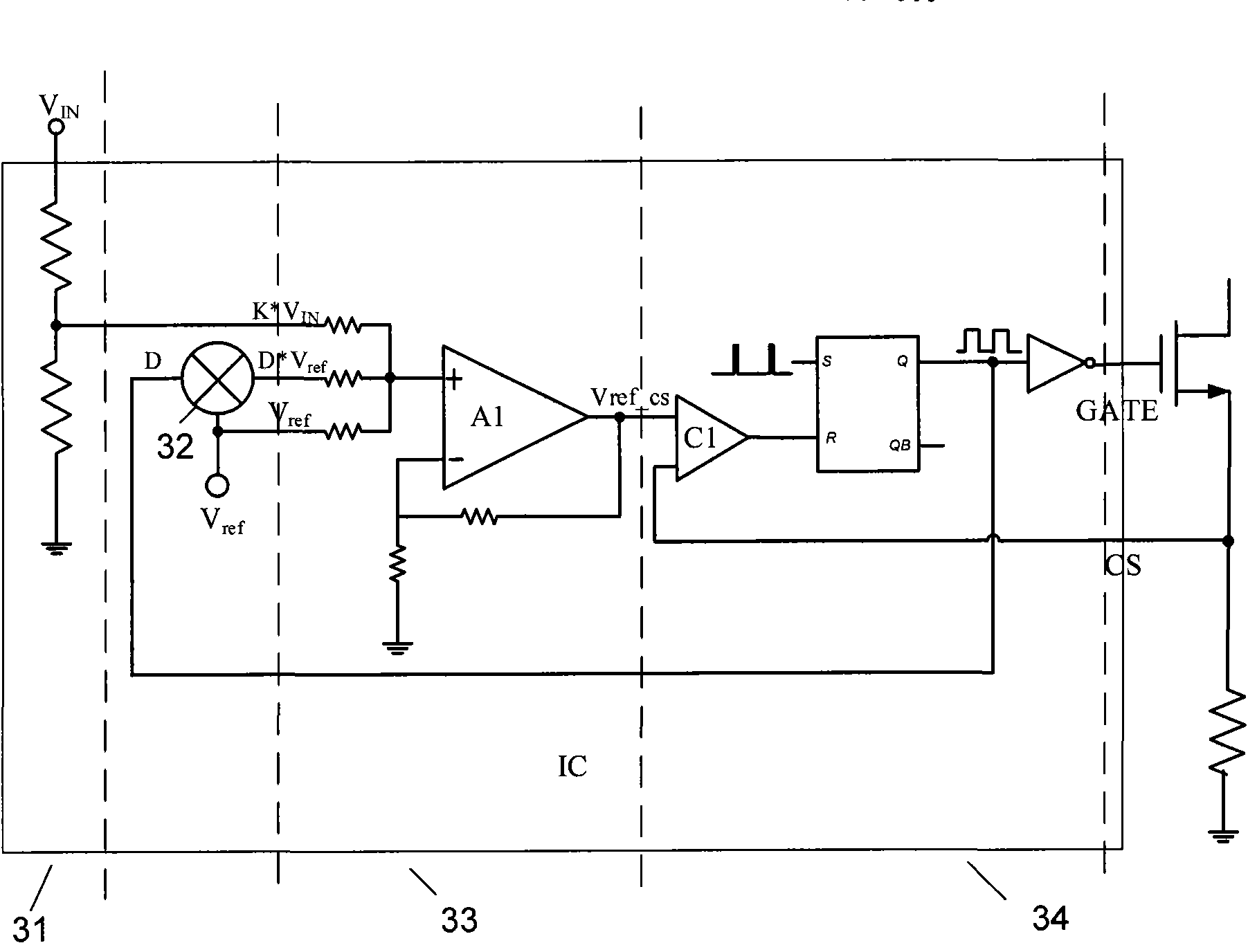

[0017] image 3 It is a schematic circuit diagram of the peak current compensation adopted in the present invention.

[0018] The circuit includes an input voltage detection circuit 31, a duty cycle detection circuit 32, an addition circuit 33 and a control circuit 34. Figure 5-7 The specific composition of each circuit is given in .

[0019] Figure 5 Yes image 3 In the circuit diagram of the input voltage detection circuit in , a resistance network is formed by connecting resistors R51 and R52 in series. By selecting a suitable ratio of resistance values, the input voltage detection circuit 31 generates k*V in signal to meet the voltage required for detection, the obtained input voltage change signal k*V in Will and V ref Added in the addition circuit 33 to control the reference of the peak current to increase with the increase of the input voltage.

[0020] Image 6 Yes image 3 The specific circuit diagram of the medium duty ratio detection circuit, the detection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com