Automatic paste releasing and positioning control device and control method thereof for coating plate

A positioning control and automatic technology, which is applied to the surface coating liquid device, coating, lead-acid battery electrodes, etc., can solve the problems of pasting pressure fluctuations, poor plate uniformity, and affecting pasting pressure. The effect of reducing the amplitude, reducing labor, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

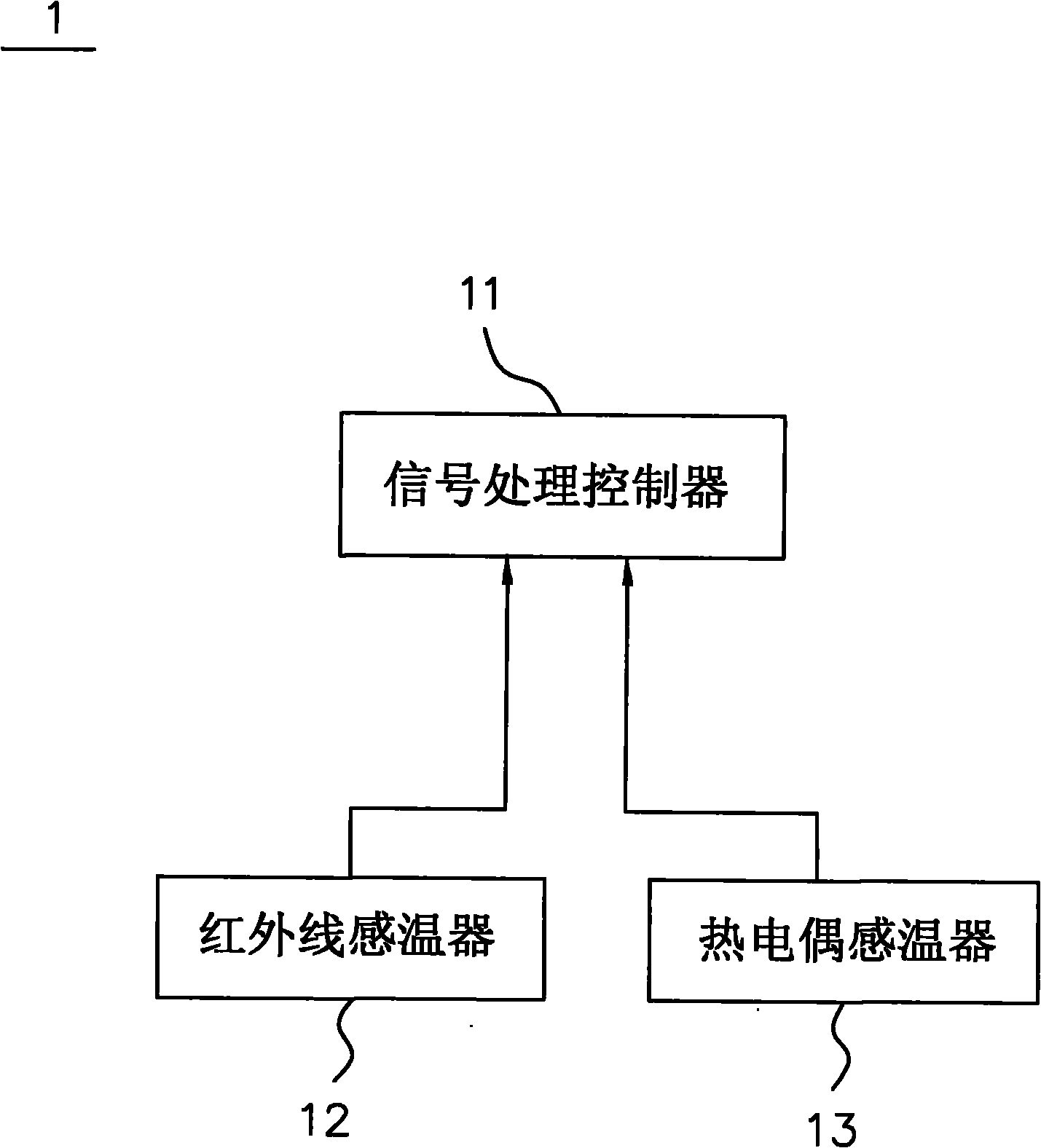

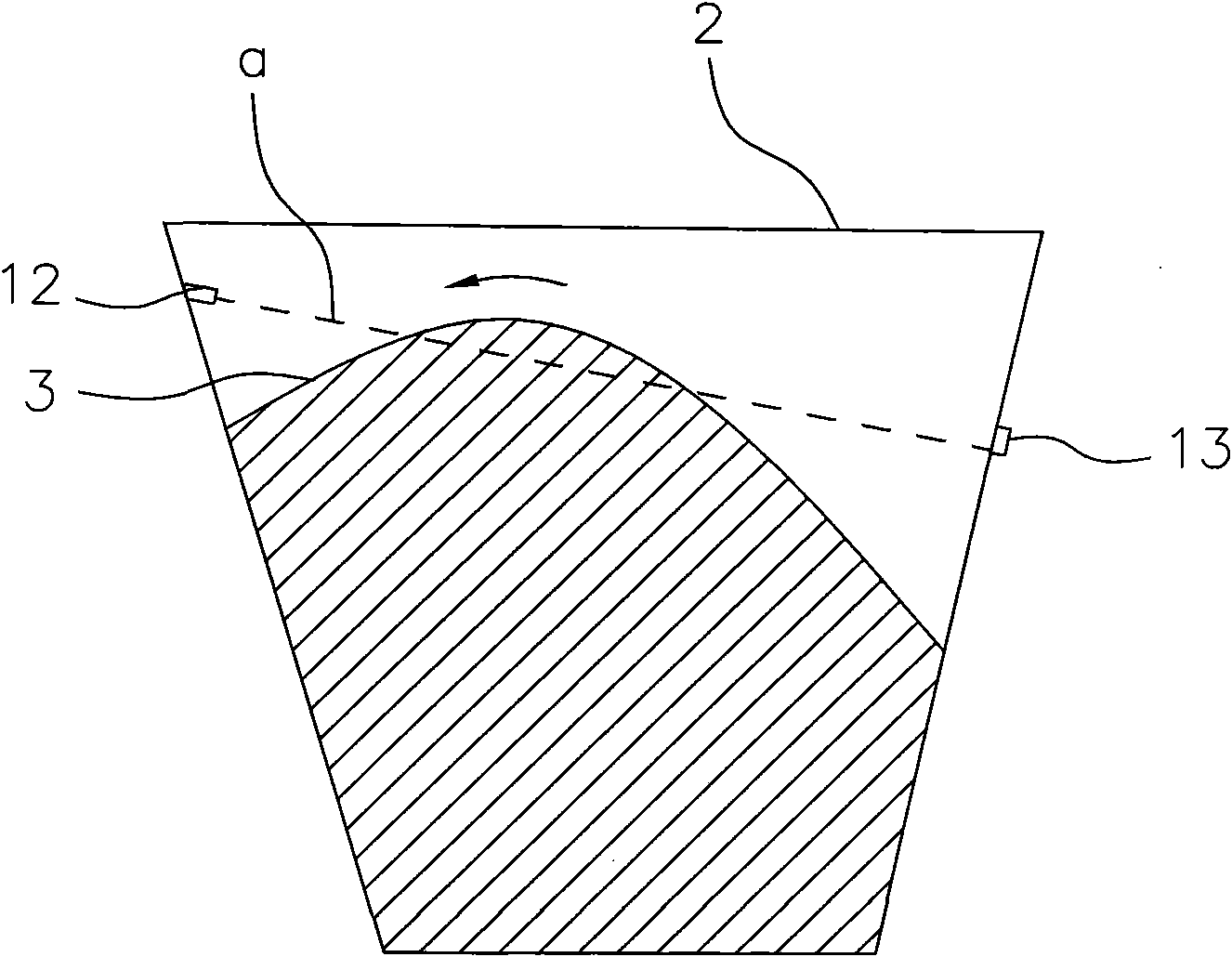

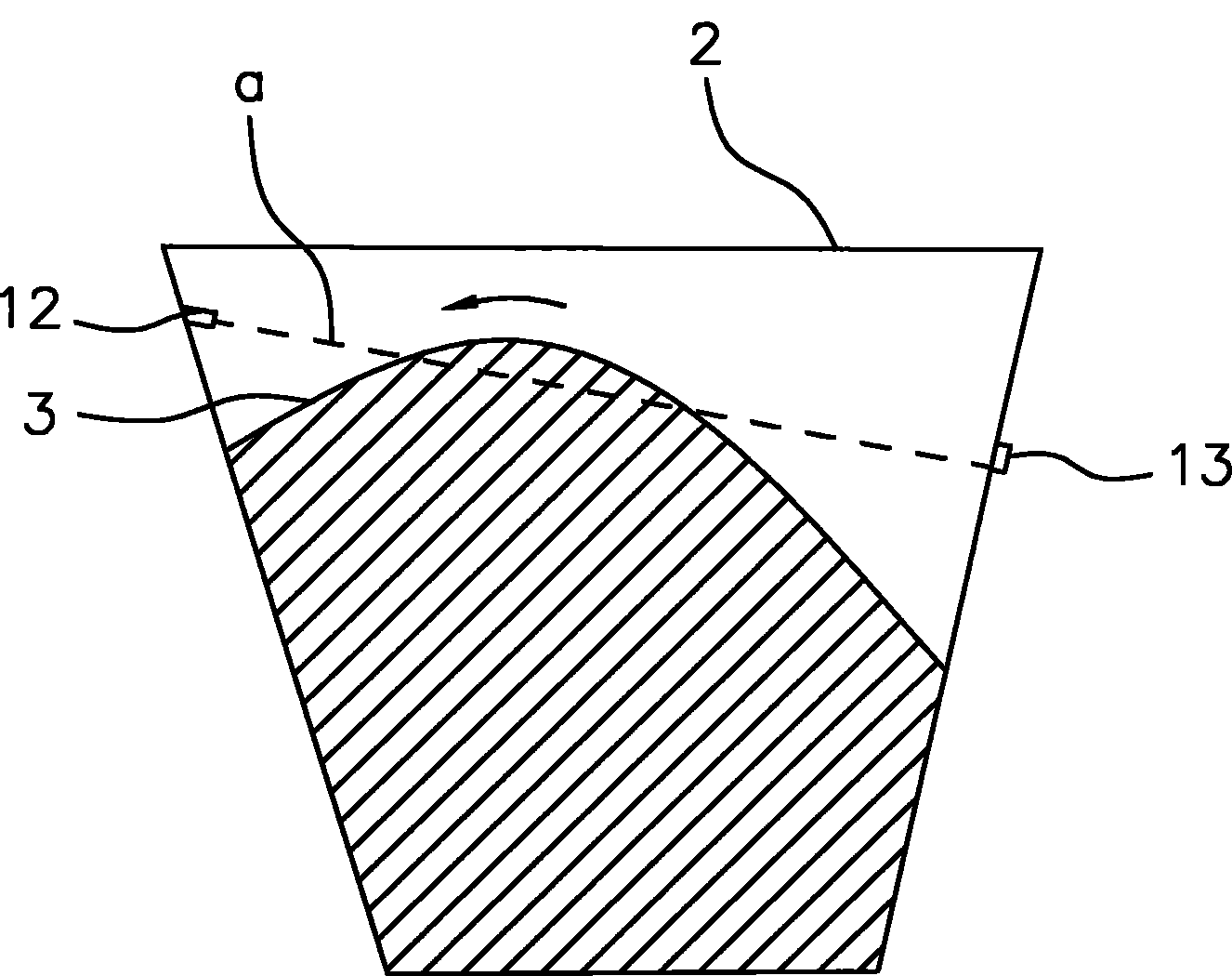

[0017] see figure 1 and figure 2 , the automatic paste-down positioning control device 1 for coating plate of the present invention is used to control the paste-down mechanism of a plate-coating machine (not shown in the figure), and the plate-coating machine is provided with a paste bucket 2 positioned below the paste-down mechanism. The plaster bucket 2 is used to hold the lead paste 3 . The automatic pasting and positioning control device 1 for coating boards includes a signal processing controller 11 , an infrared temperature sensor 12 and a thermocouple temperature sensor 13 . In this embodiment, the signal processing controller 11 is a single chip microcomputer.

[0018] The infrared temperat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap