Locating and guiding water spray device for linear cutting machine

A wire cutting machine tool and positioning and guiding technology, which is applied to the field of positioning and guiding water spray devices for wire cutting machine tools, can solve the problems of non-convergence of the liquid pressure of the emulsion, reducing the cooling chip removal effect of the electrode wire, and serious splashing of the emulsion, and achieves high efficiency. cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

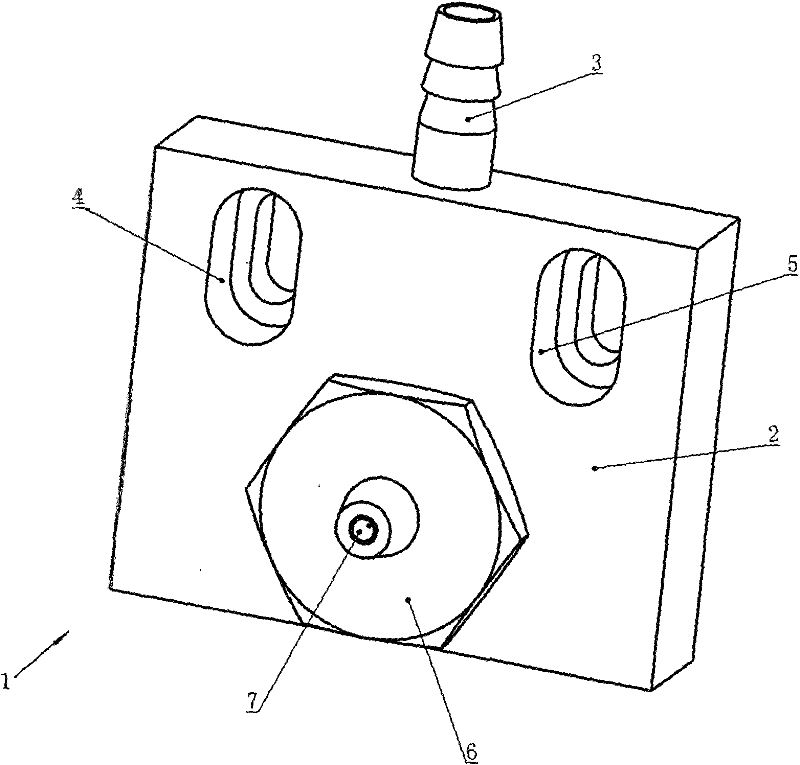

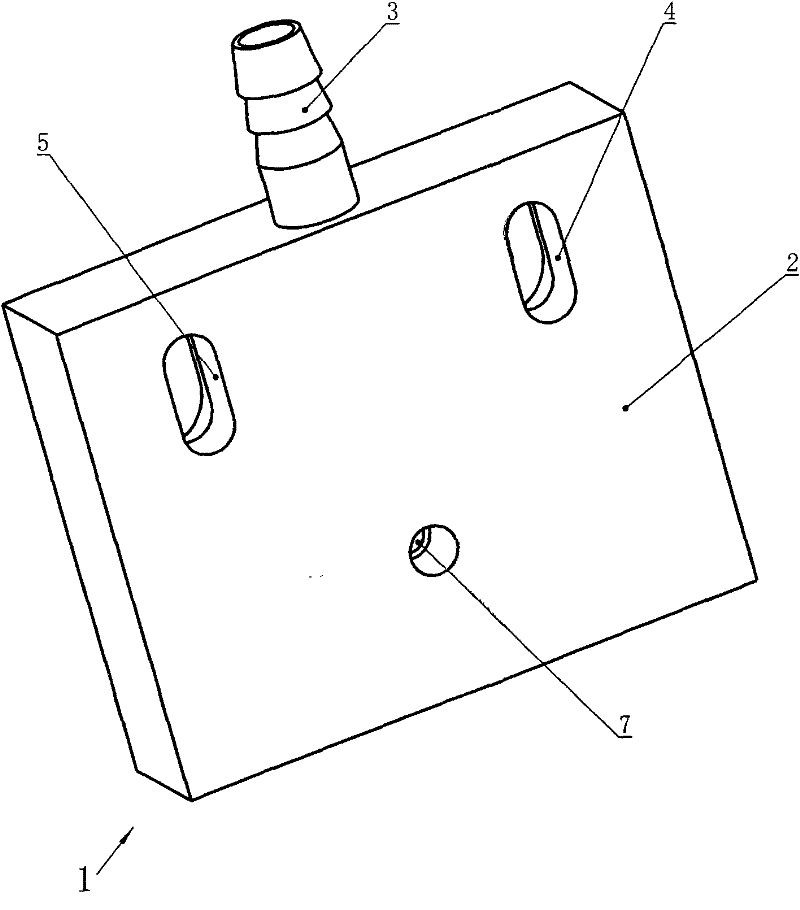

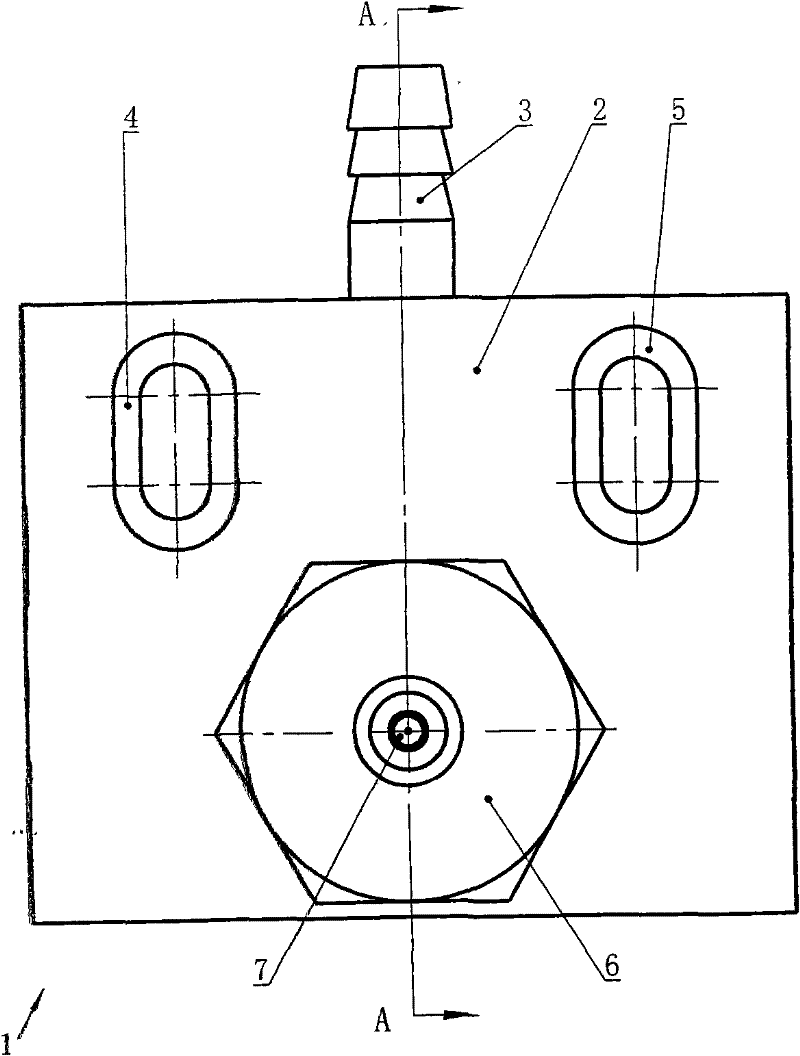

[0028] Referring to the accompanying drawings, the positioning and guiding water spray device 1 for wire cutting machine tools is composed of a water spray plate 2, a water pipe joint 3, a guide 6, a positioner 7 and a flow stabilizer 8, and the water pipe joint installation hole 20 of the water spray plate 2 A water pipe joint 3 is installed in the center; a guide 6 is installed in the guide internal thread installation hole 21 of the water spray plate 2; a locator 7 is installed in the locator installation hole 12 of the guide 6; the seal of the flow stabilizer 8 The ring plane 9 is pressed on the flow stabilizer of the water spray plate 2 and attached to the ring plane 22; the external thread connection ring 11 of the water spray plate at one end of the guide 6 is installed with a locator at the other end through the hexagonal wrench block 10 The outer convex cone of the hole 12 constitutes an integral part; the inner cavity 18 of the cone formed in the external thread conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com