Energy saver of alternating current welding machine

An energy saver, alternating current technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of inability to solve the safety and loss of electric welding machines, operator safety threats, reduce electric shock prevention, etc., to achieve reasonable structure and operation. Stable and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] Further description will be made below in conjunction with the accompanying drawings.

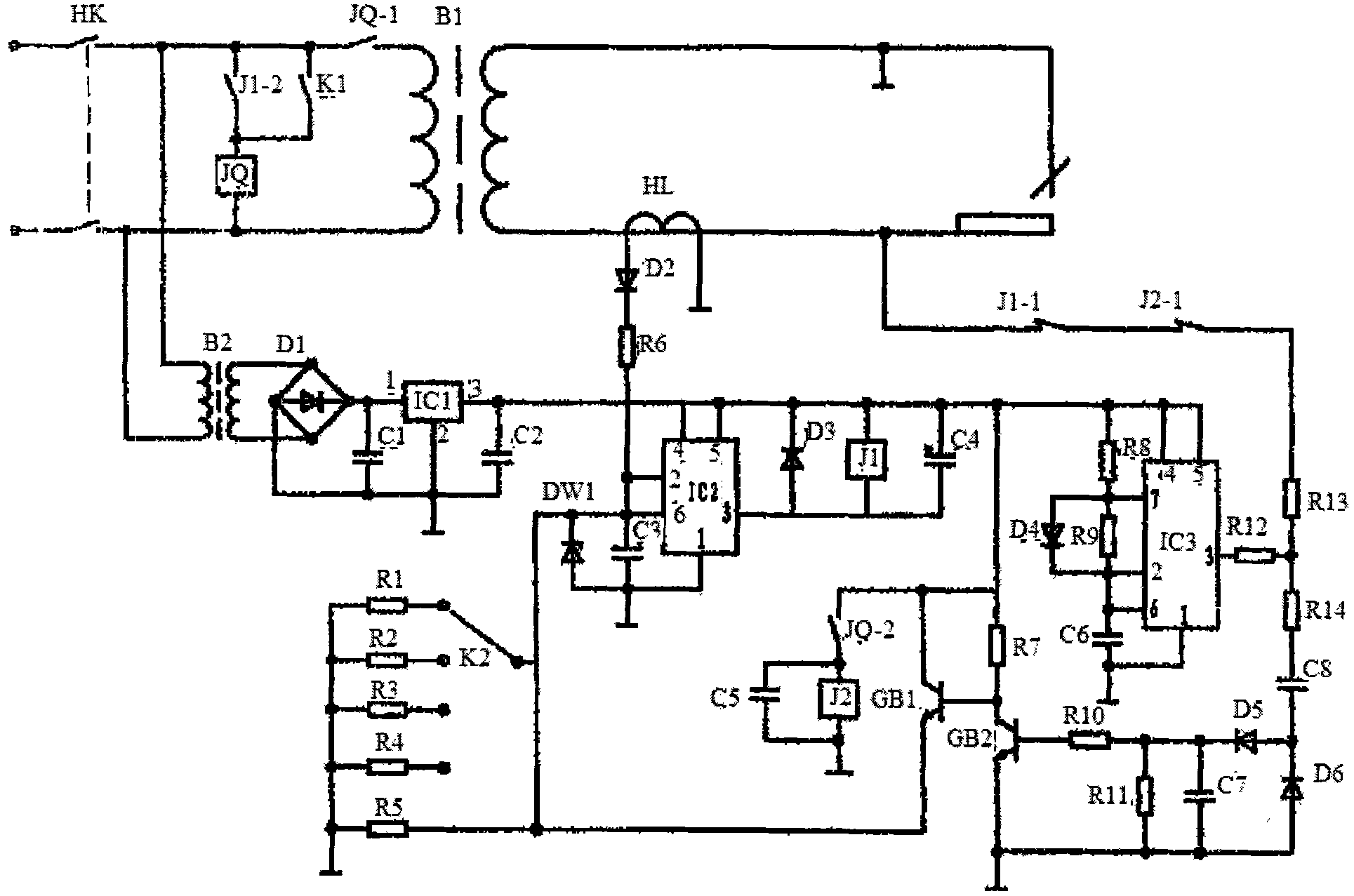

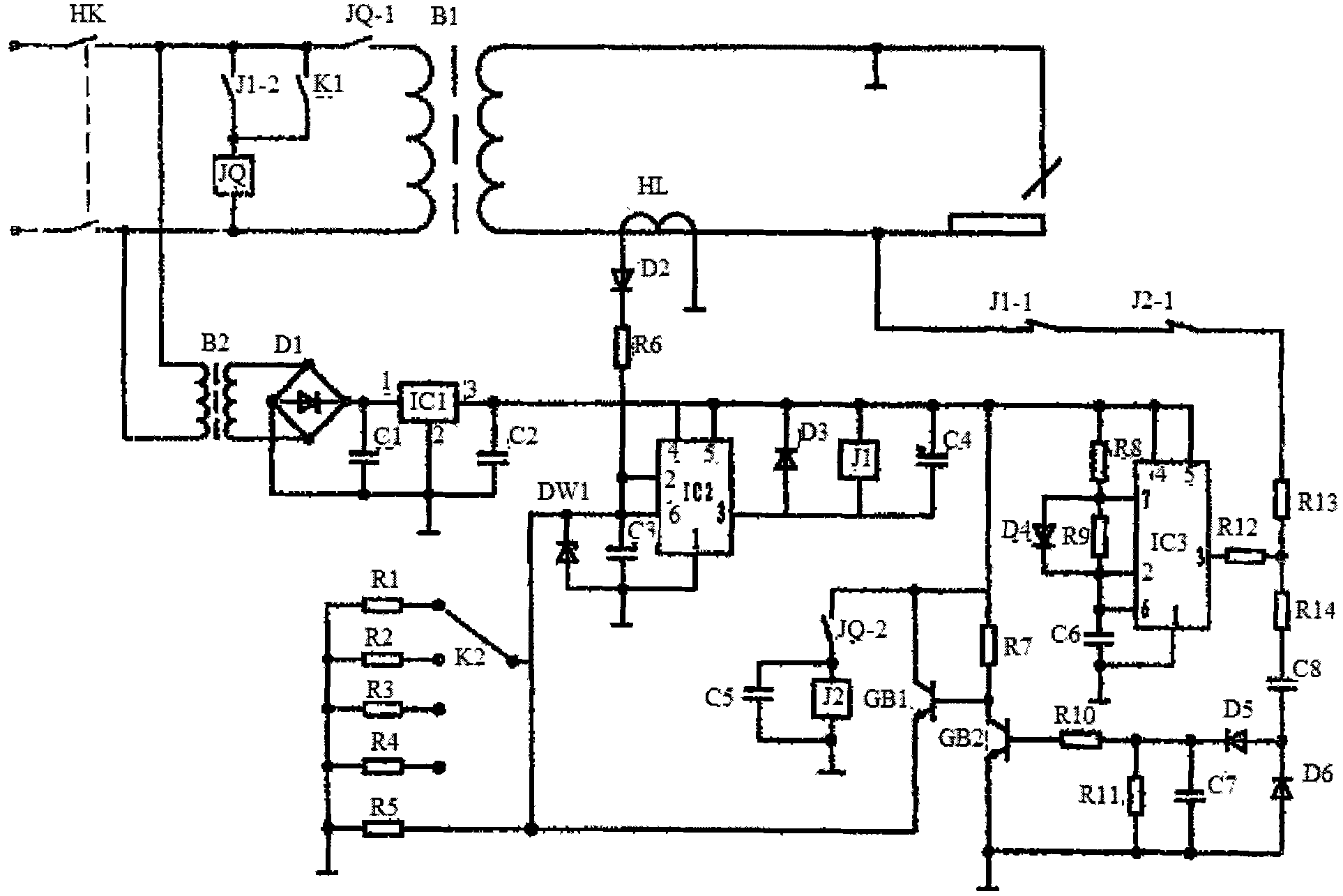

[0007] figure 1 Among them, the primary side of the welding machine transformer B1 is connected in series with the AC contactor JQ controlled by the relay J1. 2 It can be directly connected to the power supply, and forms a 12V DC power supply with the rectifier bridge D1, voltage regulator integrated block IC1, filters C1 and C2. The control circuit is composed of a trigger circuit and an oscillating circuit composed of integrated blocks IC2, IC3 and resistance-capacitance components. The input terminal of the trigger circuit integrated block IC2 is connected to the AC transformer HL on the secondary side of the welding machine transformer B2 through the resistance R6, diode D2 The input terminal of IC2 is also connected with capacitor C3, parallel voltage regulator tube DW1 and connected resistors R1~R5; the input terminal of oscillator circuit integrated block IC3 is biased by res...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap