Transverse rib automatic feeding mechanism of reinforcing mesh press welder

A technology of automatic feeding and pressure welding machine, used in welding equipment, resistance welding equipment, manufacturing tools, etc., can solve the problems of poor material distribution reliability and low efficiency, and achieve the effect of high material distribution efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

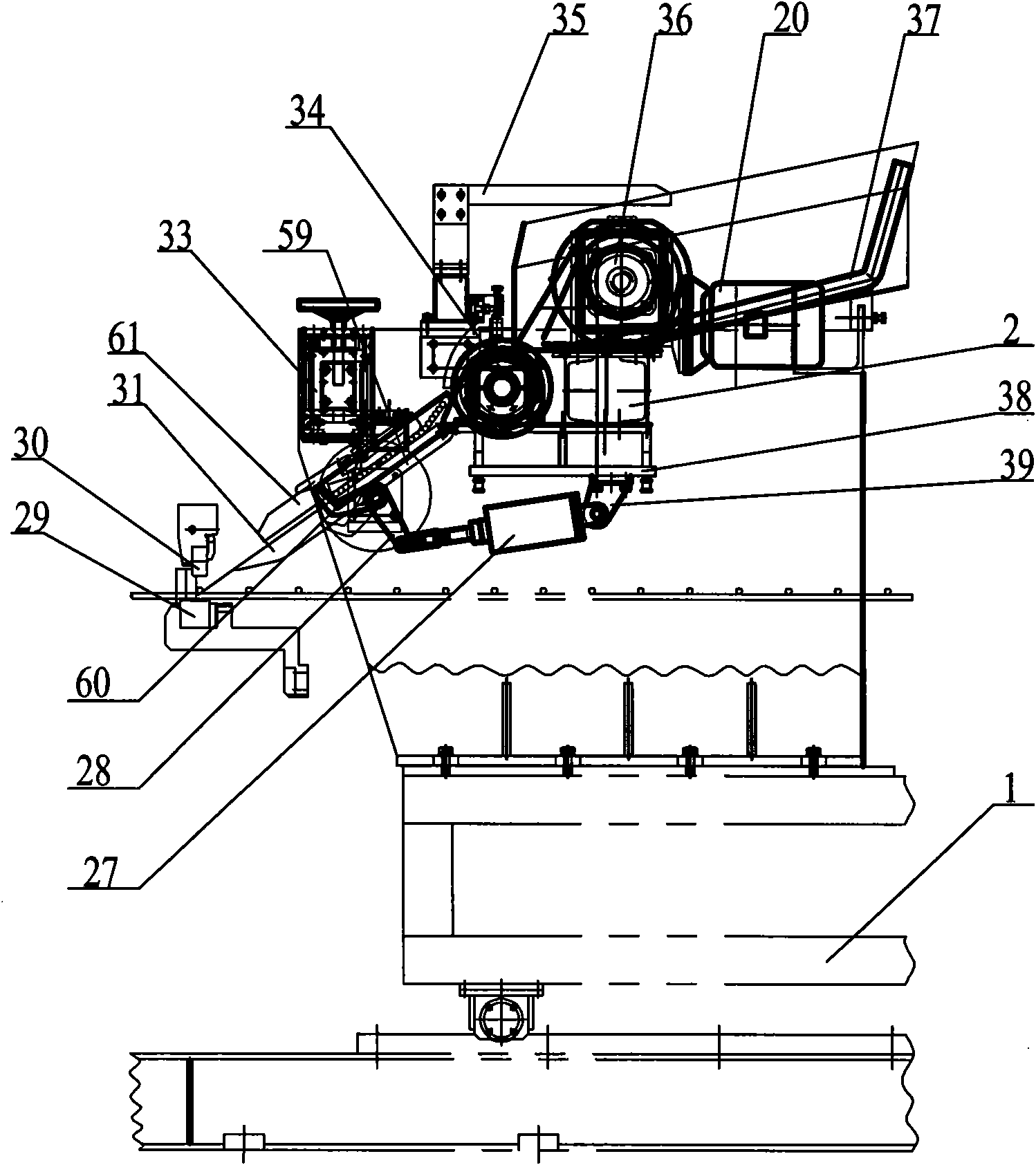

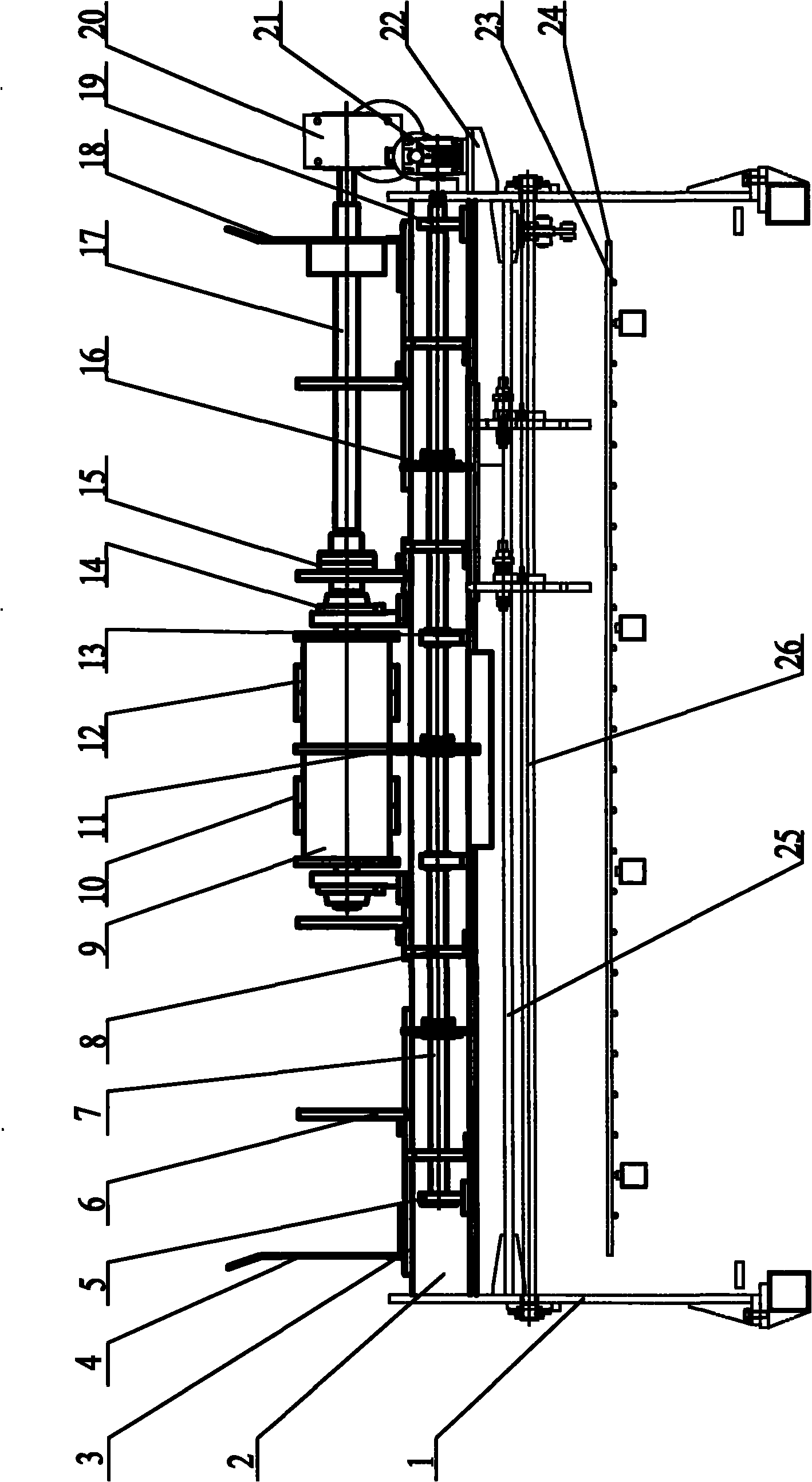

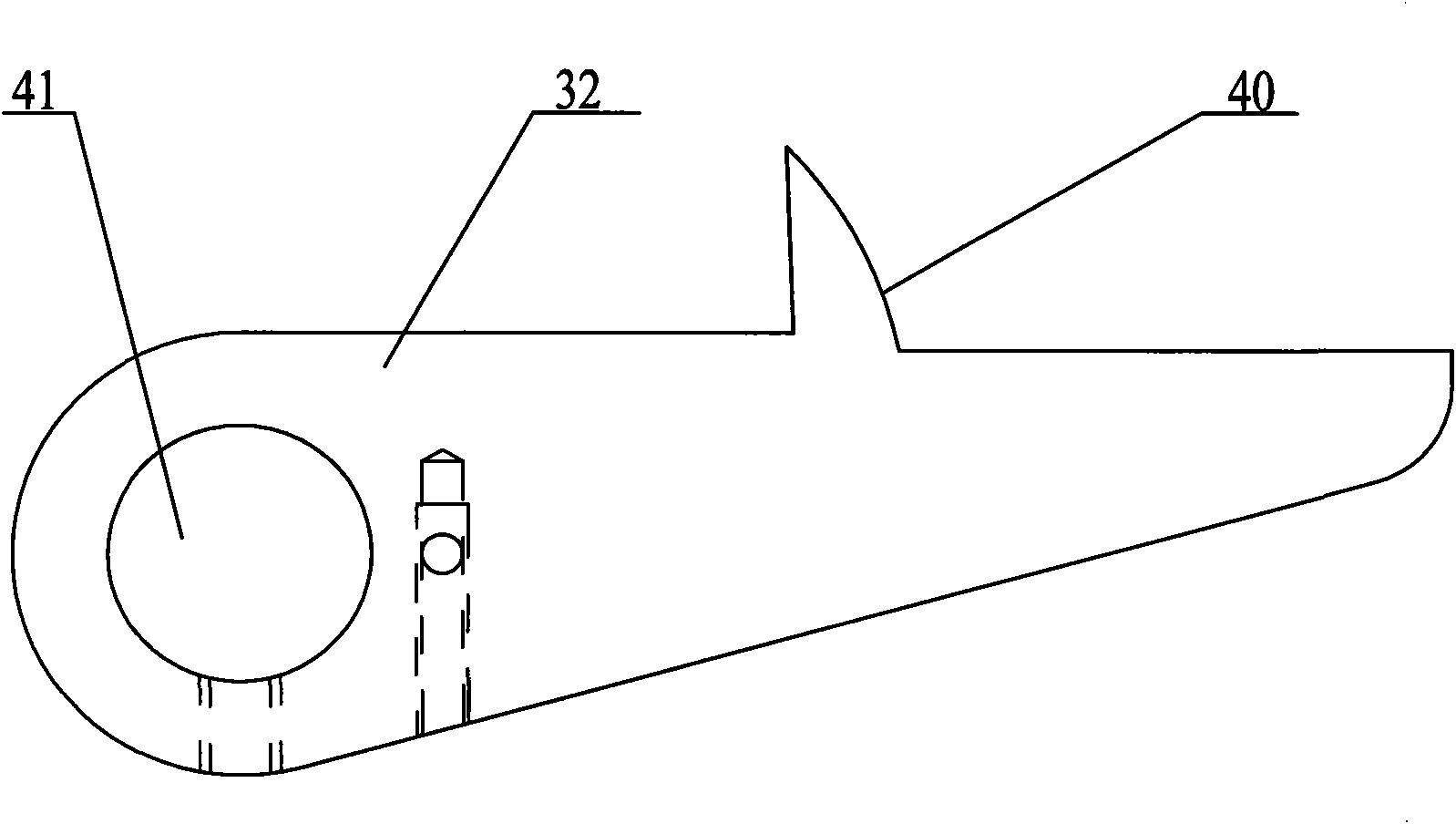

[0017] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0018] Such as Figure 1~Figure 8 Shown: the present invention includes a fixed side plate 1, a mounting beam 2, an adjustment plate 3, a left limit plate 4, a left support seat 5, a first guide seat 6, a long shaft 7, a second guide seat 8, a rotating drum 9, Magnet box 10, distribution plate 11, magnet 12, intermediate support seat 13, bearing seat 14, first coupling 15, rotating guide plate 16, connecting shaft 17, right limit plate 18, left support seat 19, first Reducer 20, second reducer 21, mounting seat 22, transverse ribs 23, longitudinal ribs 24, blanking bracket 25, guide trough bracket 26, cylinder 27, pull plate 28, lower electrode 29, upper electrode 30, lower guide material Plate 31, guide trough inserting hook 32, guide trough beam 33, feeding mechanism 34, material limiting plate 25, transverse rib discharging mechanism 36, material receiving fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com