Method for improving quality and reaction period in production of gasoline by using low-carbon hydrocarbons

A gasoline quality and reaction cycle technology, applied in the petroleum industry, liquid hydrocarbon mixture production, etc., can solve the problem of gasoline octane number is not very ideal, achieve the effect of improving gasoline composition distribution, simple and easy method, and enhancing gasoline quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

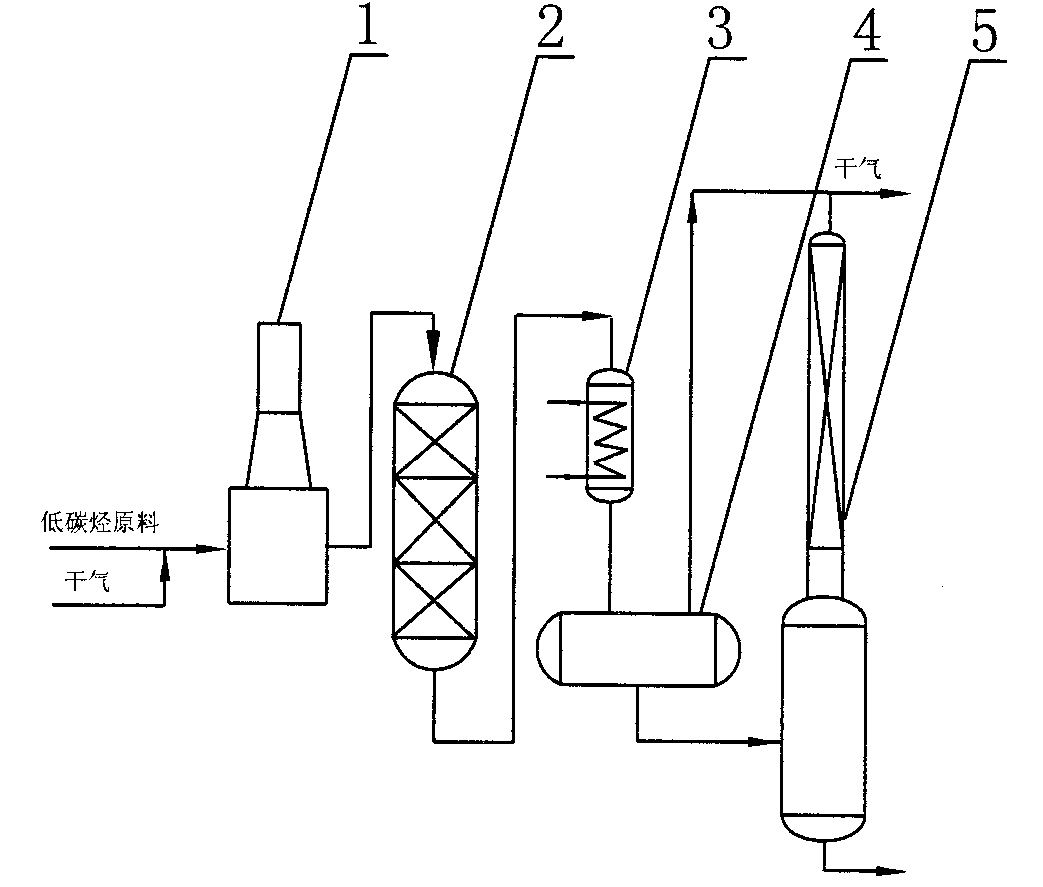

[0016] The raw material and dry gas enter the heating furnace 1 in a ratio of 100:10 and heat it to 350--450°C, then mix and enter the reactor 2 with a pressure of 1.5-2.5Mpa, and a series of cracking or dehydrogenation and oligomerization will occur under the action of the catalyst , isomerization, dehydrogenation and other two-way reversible reactions, the reaction liquid 2 is cooled by the cooler 3 to about 40°C and enters the vapor-liquid separation tank 4 for buffering, and the separated liquid phase is flashed out in the flash tank 5 with a temperature of 40-80°C The dry gas within C4 is mixed with the rich gas at the top of the vapor-liquid separation tank 4 out of the device, and the naphtha at the bottom of the flash tank 5 is sent to the refining equipment for treatment on the distillation range index to obtain an octane number of 98, a sulfur content of 3-5ppm, High-grade clean gasoline with 3% olefin content and 29% aromatic content. The operating cycle is 60 days....

Embodiment 2

[0018] The raw material and dry gas enter the heating furnace 1 in a ratio of 100:6 and are heated to 300-350°C, and then mixed into the reactor 2 with a pressure of 1.0-2.0Mpa. Under the action of the catalyst, a series of cracking or dehydrogenation, oligomerization, Two-way reversible reactions such as isomerization and dehydrogenation, the reaction liquid is cooled by the cooler 3 to about 40°C and enters the vapor-liquid separation tank 4 for buffering, and the separated liquid phase is flashed to the flash tank 5 at a temperature of 40-80°C to flash out C4 The dry gas is mixed with the rich gas at the top of the vapor-liquid separation tank 4 out of the device, and the naphtha at the bottom of the flash tank 5 is sent to the refining equipment for treatment on the distillation range index to obtain an octane number of 97, a sulfur content of 3-6ppm, and an olefin content 5% high-grade clean gasoline with 32% aromatic content. The operating cycle is 58 days.

Embodiment 3

[0020] The raw material and dry gas enter the heating furnace 1 in a ratio of 100:4 and are heated to 250-300°C, and then mixed into the reactor 2 with a pressure of 0.8-1.5Mpa. Under the action of the catalyst, a series of cracking or dehydrogenation, oligomerization, Two-way reversible reactions such as isomerization and dehydrogenation, the reaction liquid is cooled by the cooler 3 to about 40°C and enters the vapor-liquid separation tank 4 for buffering, and the separated liquid phase is flashed to the flash tank 5 at a temperature of 40-80°C to flash out C4 The dry gas is mixed with the rich gas at the top of the vapor-liquid separation tank 4 out of the device, and the naphtha at the bottom of the flash tank 5 is sent to the refining equipment for treatment on the distillation range index to obtain an octane number of 96, a sulfur content of 3-8ppm, and an olefin content 4-8%, high-grade clean gasoline with 35% aromatic content. 55 days running cycle

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com