Method for recovering flue gas waste heat of aluminum electrolysis cell

An aluminum electrolytic cell and flue gas waste heat technology, applied in the field of heat energy recovery devices, can solve the problems of large longitudinal depth, poor resistance on both sides of the purification system, large structure, etc. Low resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Now illustrate the present invention in conjunction with accompanying drawing and embodiment.

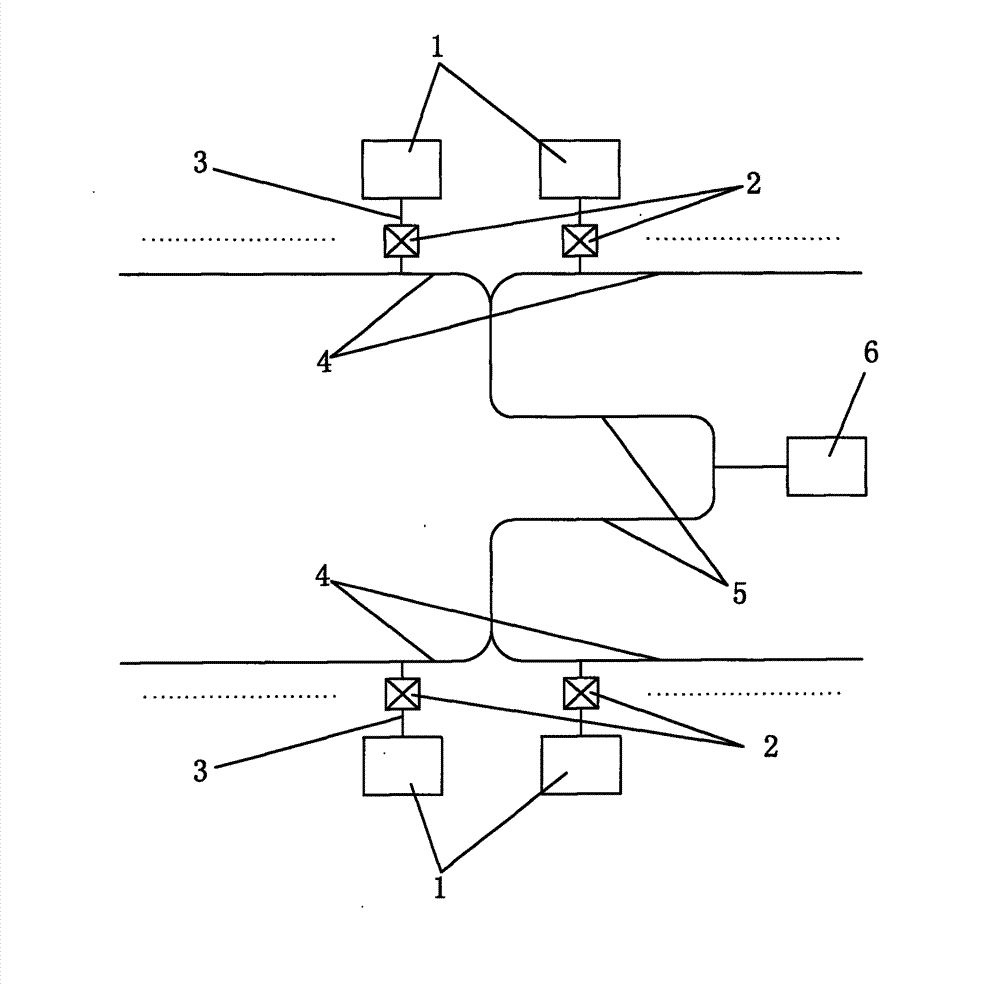

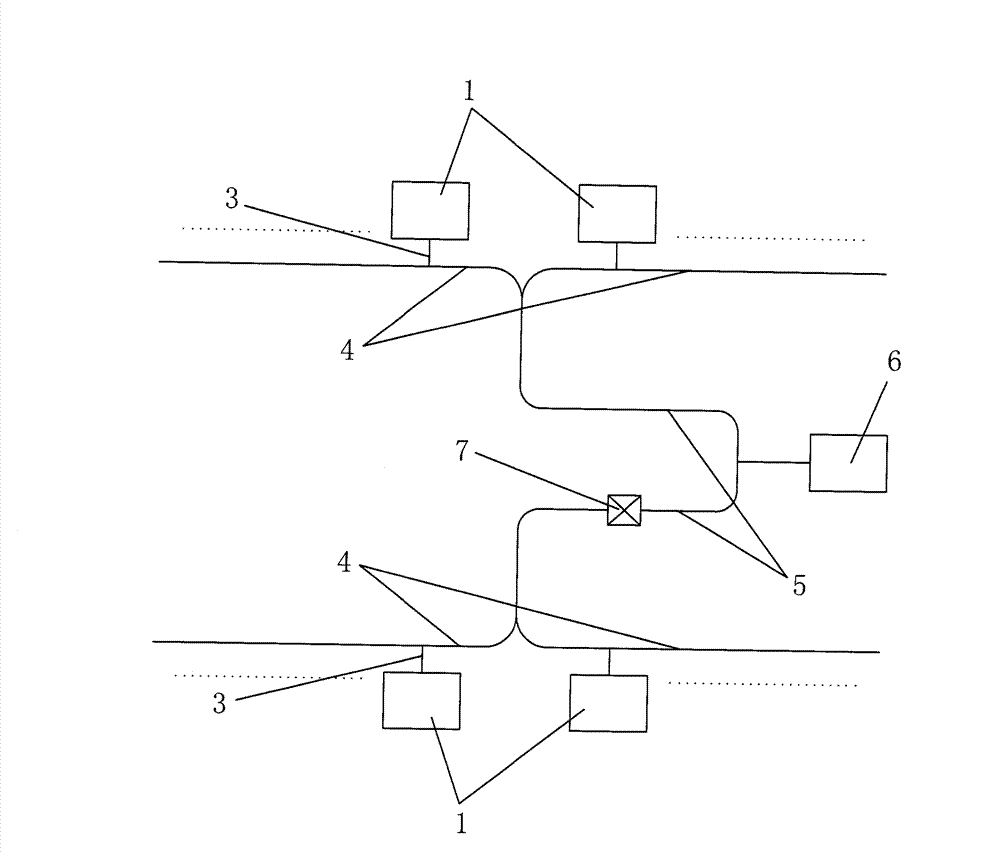

[0011] Such as figure 1 In the shown method for recovering waste heat from flue gas from an aluminum electrolytic cell, the flue gas discharged from an aluminum electrolytic cell 1 sequentially passes through a smoke exhaust branch pipe 3, a smoke exhaust main pipe 4, and a smoke exhaust main pipe 5, and finally is discharged through an induced draft fan 6. The present invention A waste heat recoverer 2 for recovering the flue gas directly discharged from the aluminum electrolytic cell 1 is installed on the exhaust branch pipe 3 of each aluminum electrolytic cell 1 , and each waste heat recovery device 2 corresponds to one aluminum electrolytic cell 1 . Every additional waste heat recovery device 2 is installed on the smoke exhaust branch pipe 3 of the aluminum electrolytic cell 1 that is the closest to the pipeline distance of the induced draft fan. The arrangement of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com