Synchronous end seal remover

A terminal and U-shaped technology, applied in the field of end seal removal tools, can solve the problems of waste, track plate damage, low efficiency, etc., and achieve the effect of simple structure and reasonable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

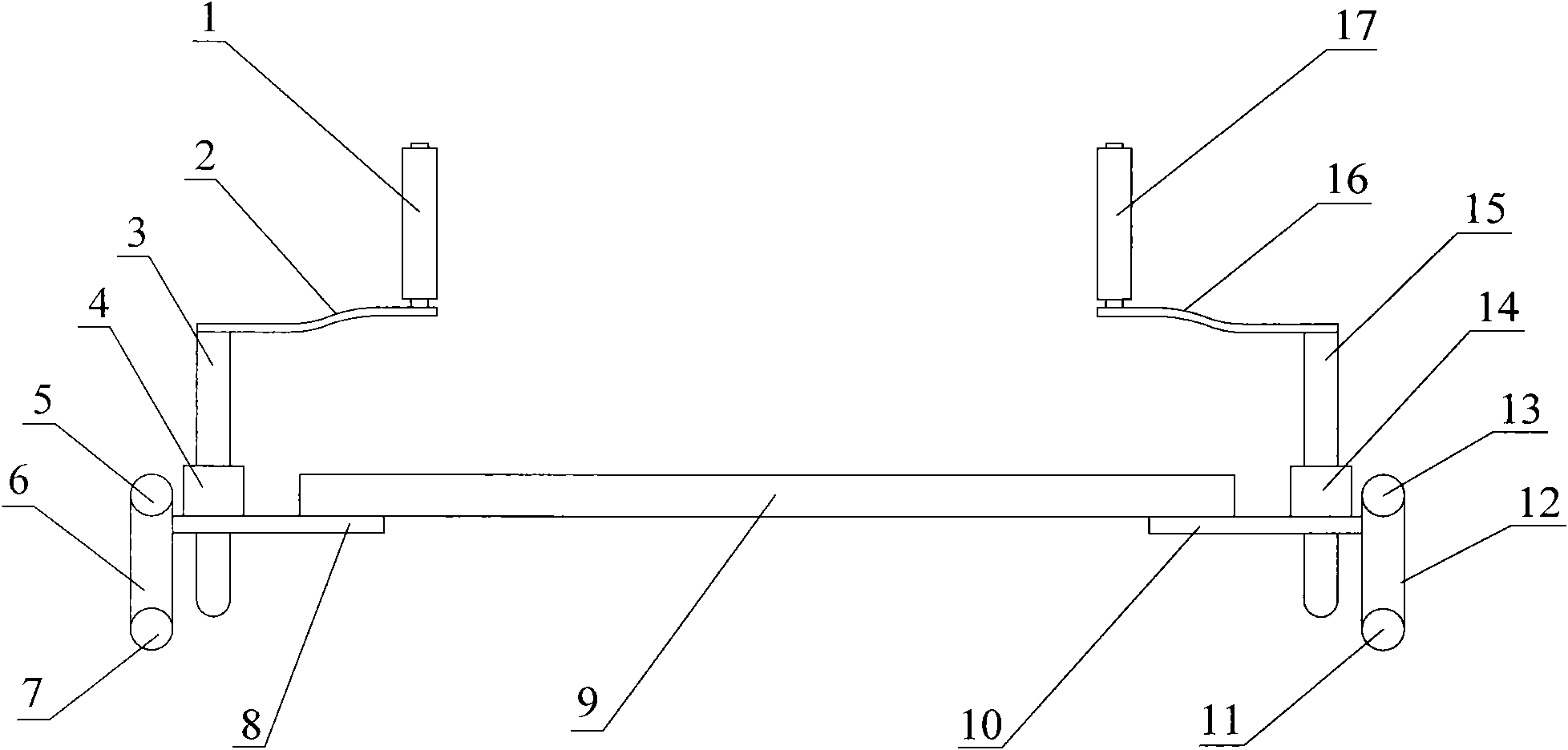

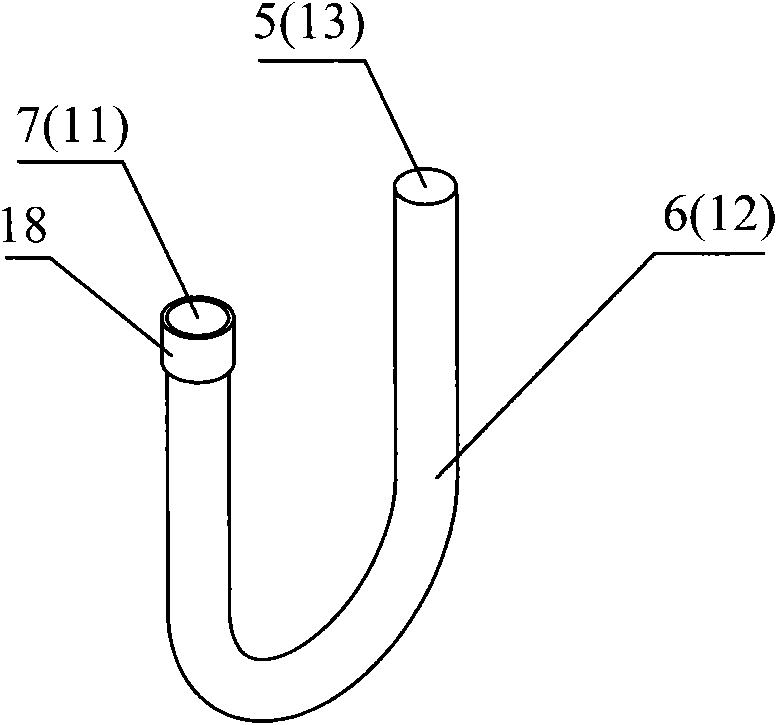

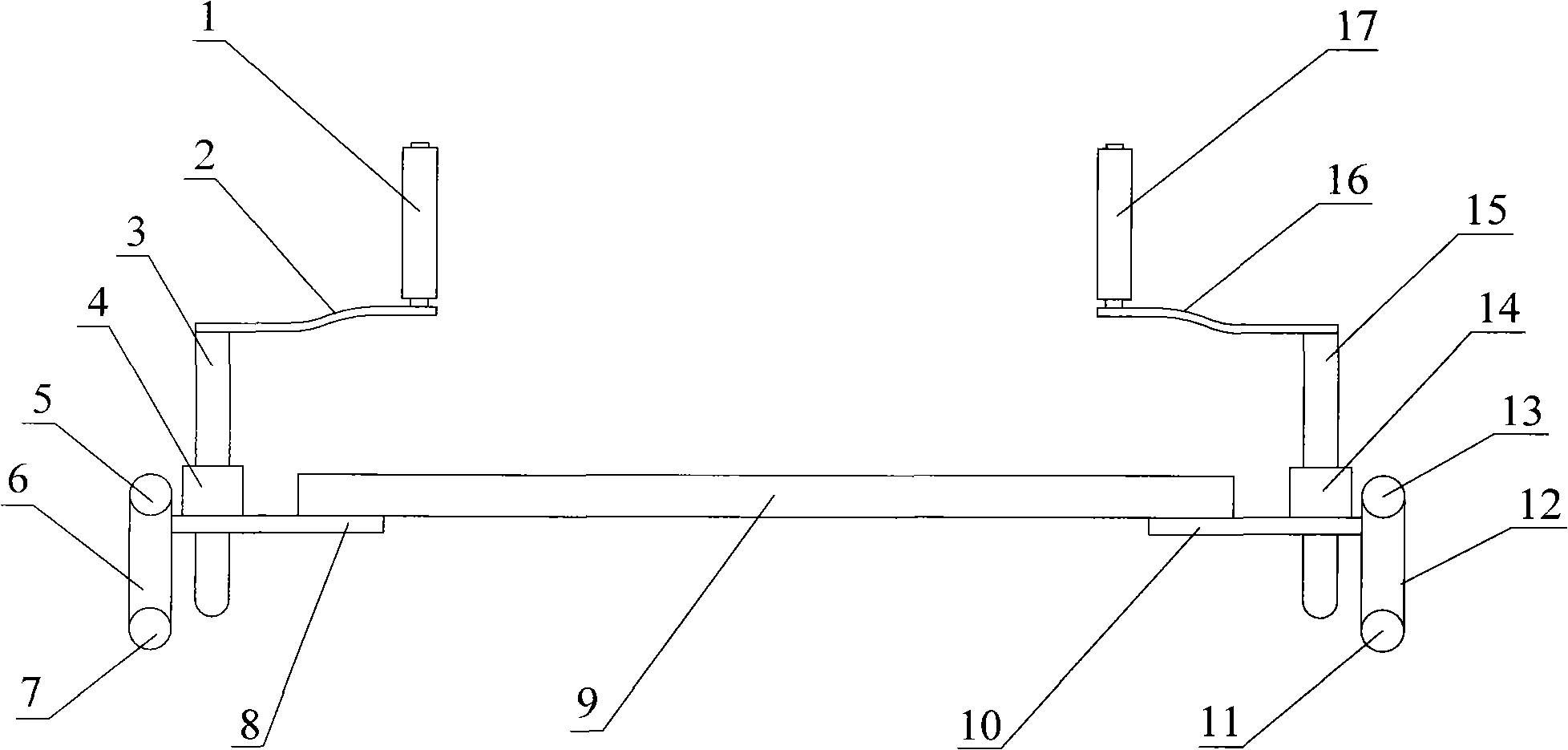

[0022] Such as figure 1 The shown synchronous end seal remover includes U-shaped component 1 6, U-shaped component 2 12, base plate 1 8, base plate 2 10, screw 1 3, screw 2 15, connecting rod 1 2, connecting rod 2 16, Crank 1, crank 2 17, nut 1 4, nut 2 14 and connecting rod 3 8; the U-shaped member 1 6 and U-shaped member 2 12 adopt U-shaped threaded steel, and the base plate 8 and base plate 10 adopt steel plates , the U-shaped component 6 is installed on the base plate 8, the nut 4 is located on one side of the U-shaped component 6 and fixed on the base plate 8, and the screw rod 3 is sleeved in the nut 4 and passed through Through the base plate one 8, the screw rod one 3 is connected with the crank handle one 1 through the connecting rod one 2; the U-shaped component two 12 is installed on the base plate two 10, the screw rod two 15 is located on the side of the U-shaped component two 12 and Fixed on the base plate 2 10, the screw rod 2 15 is sleeved in the nut 2 14 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com