Naval vessel watertight door

A technology for watertight doors and ships, which is applied in the arrangement of watertight doors, sealing devices, window/door frames, etc., can solve the problems of difficult opening and closing of watertight doors, wave deformation of the hull facade, and poor sealing, and achieves strong practicability and reliability. Promotion value, good shock resistance, not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

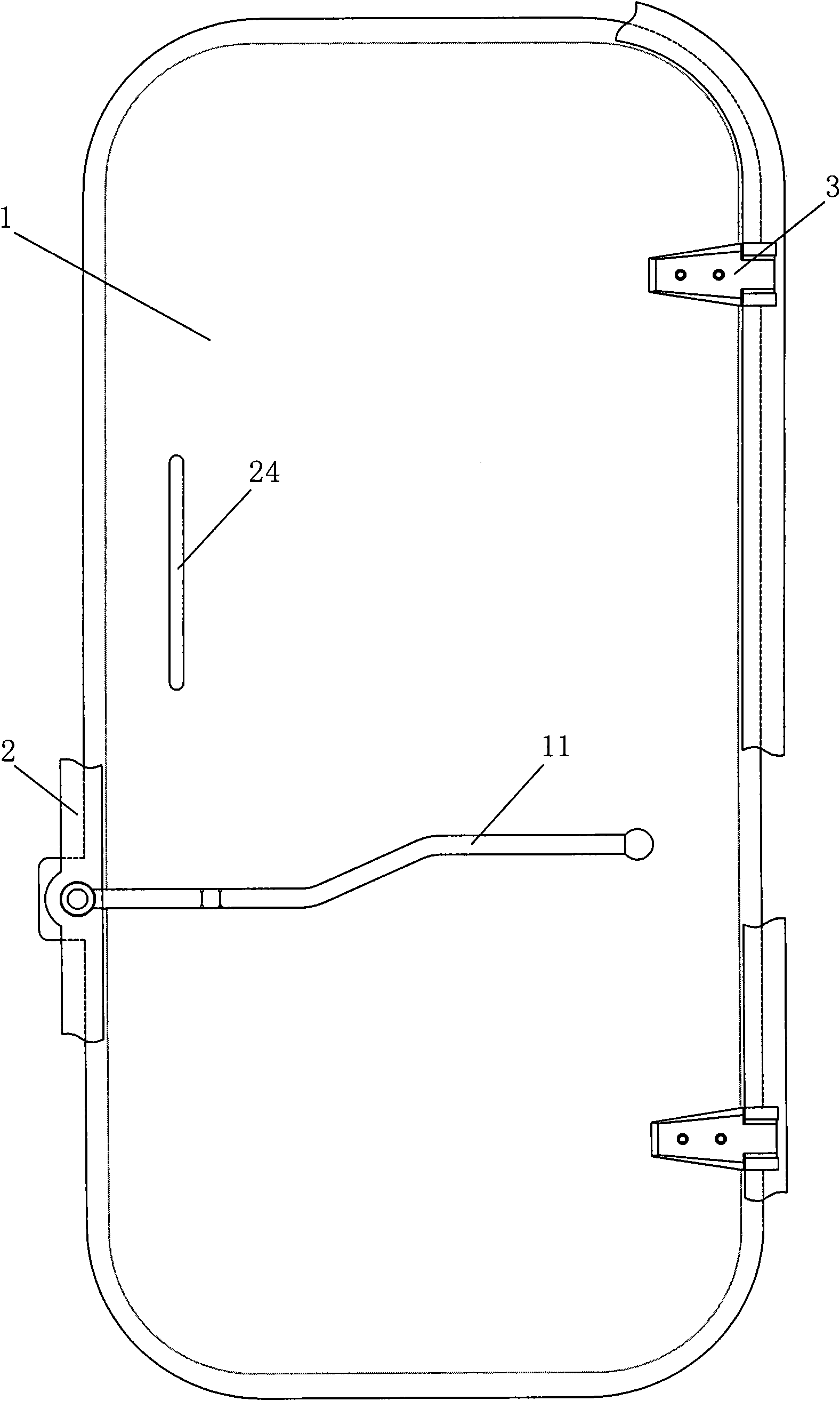

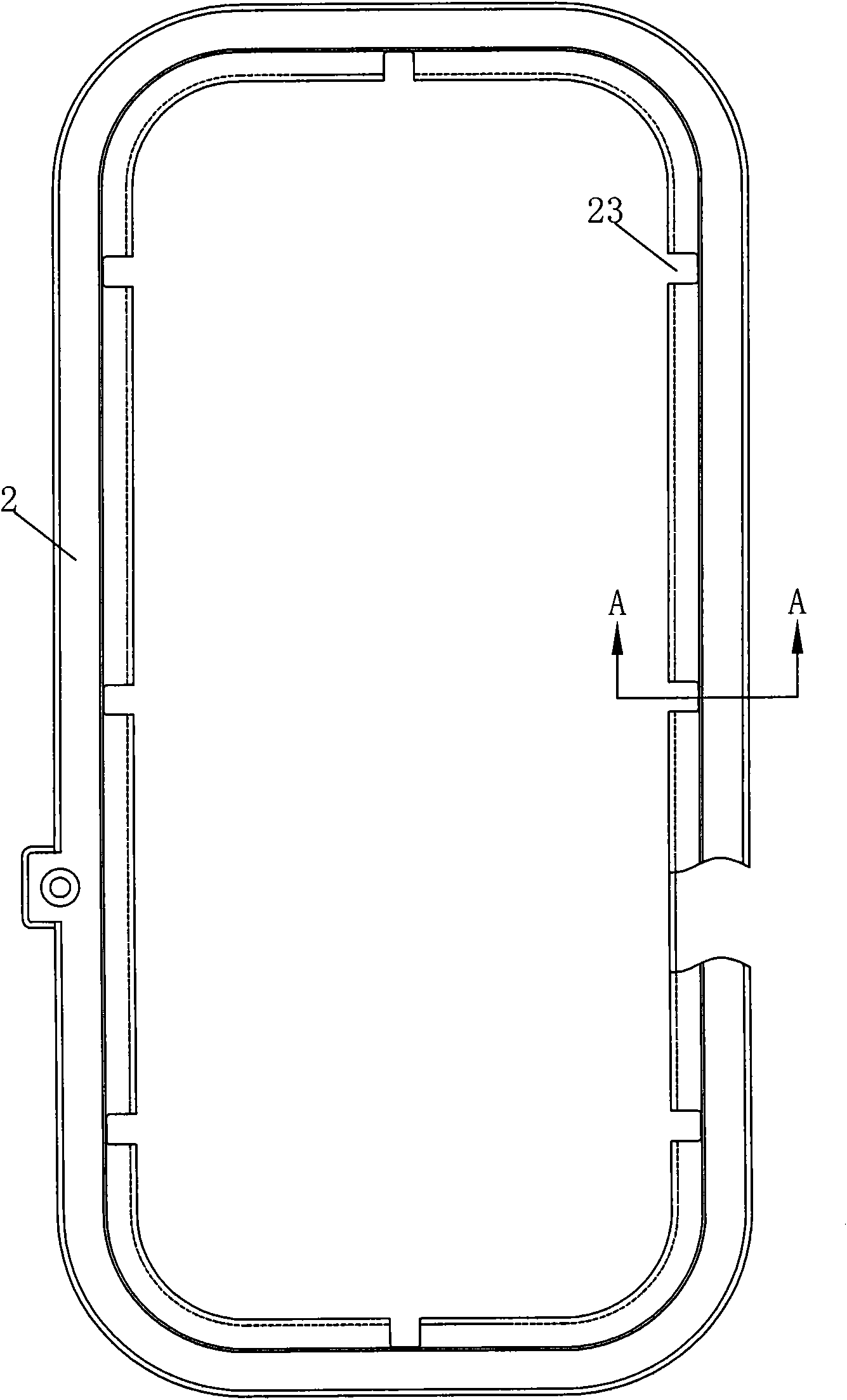

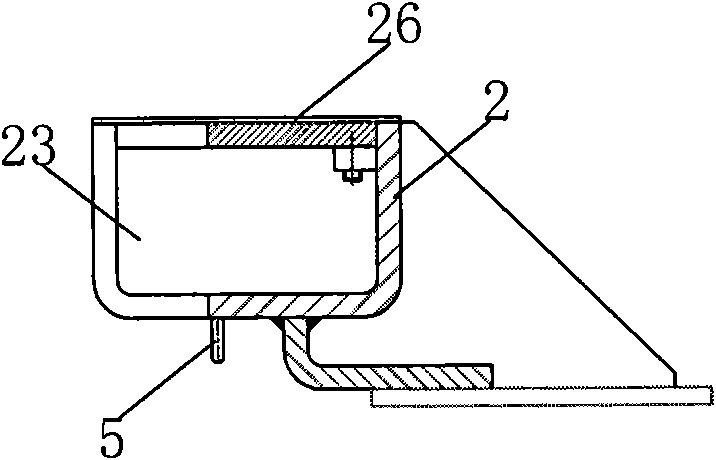

[0031] Such as Figure 1 to Figure 13 As shown, the ship watertight door of the present invention includes a door panel 1 and a door frame 2, both of which are rectangular. The door frame 2 is installed on the hull, and the door panel 1 and the door frame 2 are connected by two door hinges 3 arranged on one side. The door panel 1 is provided with inner and outer handles 24 to facilitate the opening and closing of the door panel 1 . The inner periphery of the door panel 1 is provided with an annular sealing rubber strip 4, and the fixing mode of the sealing rubber strip 4 is to set a fixing groove around the door panel in the inner side of the door panel 1, and the sealing rubber strip 4 is installed in the fixing groove. The outer periphery of the door frame 2 is provided with an annular pressing knife 5 that can cooperate with the sealing rubber strip 4 to form a seal. When the door panel 1 is closed, the pressing knife 5 is pressed into the sealing rubber strip 4 to form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com