Electric stapler and operation method thereof

A working method and technology for a stapler, which are applied to staple tools, manufacturing tools, staple staple tools, etc., can solve problems such as reduced penetration performance, reduced clamping force, and enlarged product shape, and achieve the performance of preventing binding. The effect of decreasing the number of products and suppressing the increase in the variety of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] An electric stapler according to an exemplary embodiment of the present invention will be described with reference to the drawings. In addition, the electric stapler of the exemplary embodiment has the same structure as the general electric stapler 1 already described. Therefore, the same reference numerals are given to the parts composed of the same structure as the already explained structure, and the explanation thereof is omitted in the typical embodiment.

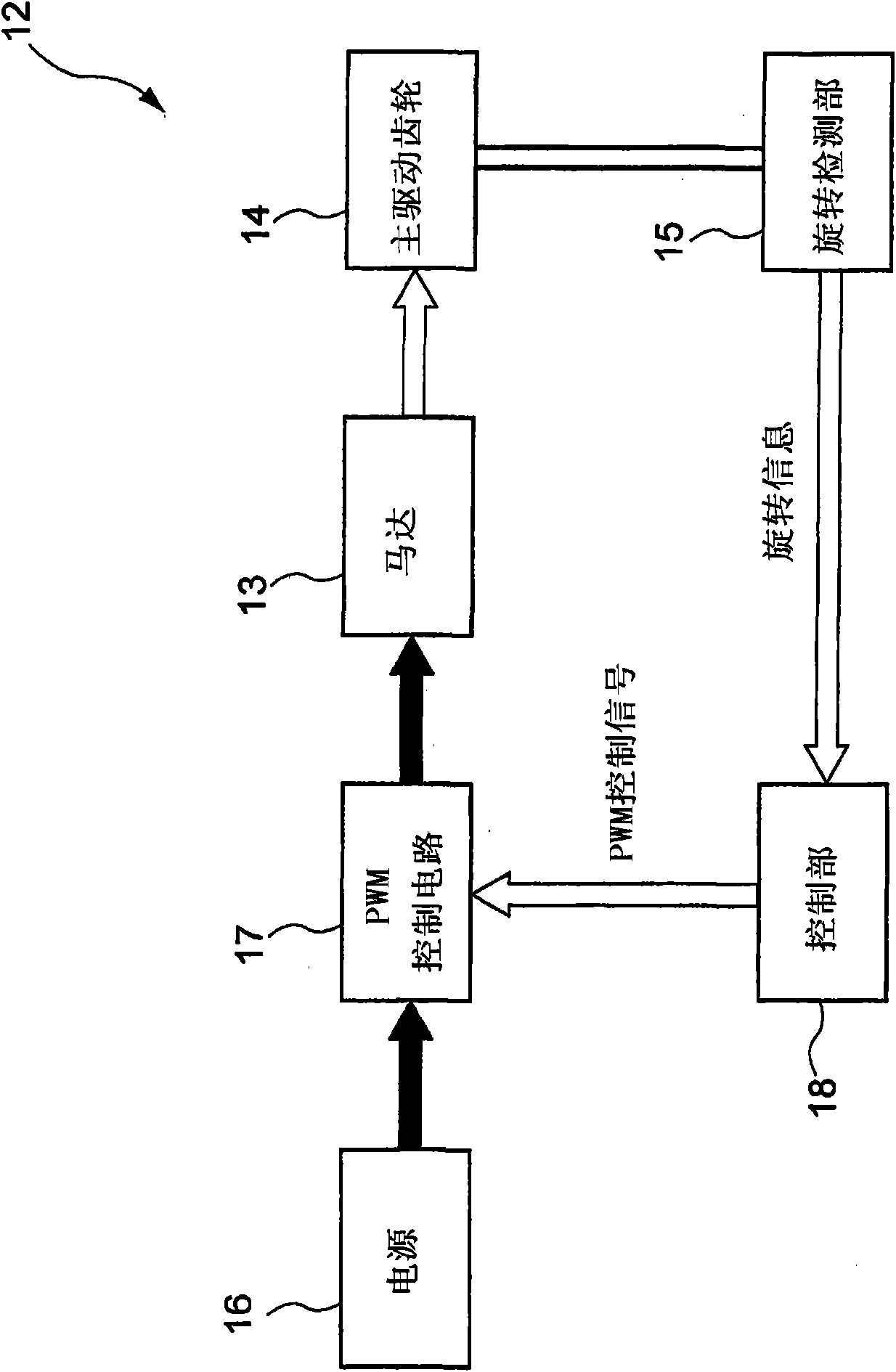

[0051] figure 1 It is a block diagram showing a schematic configuration of a functional part that performs drive control of the motor in the electric stapler of the exemplary embodiment.

[0052] The electric stapler 12 has: a motor 13; a main drive gear 14 that is rotationally driven by the motor 13; a rotation detection unit (rotation state detection device) 15 that detects the rotation state of the main drive gear 14; and supplies power from the power source 16 to the motor 13 A PWM (Pulse Width Modulation) cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com