Vacuum and dynamic compaction synchronization method

A simultaneous method and vacuum technology, applied in soil protection, construction, infrastructure engineering, etc., can solve problems such as failure to reach overload level, limited pressure of drainage consolidation method, engineering failure, etc., to eliminate post-construction settlement and settlement. poor, improving drainage conditions, increasing the effect of permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

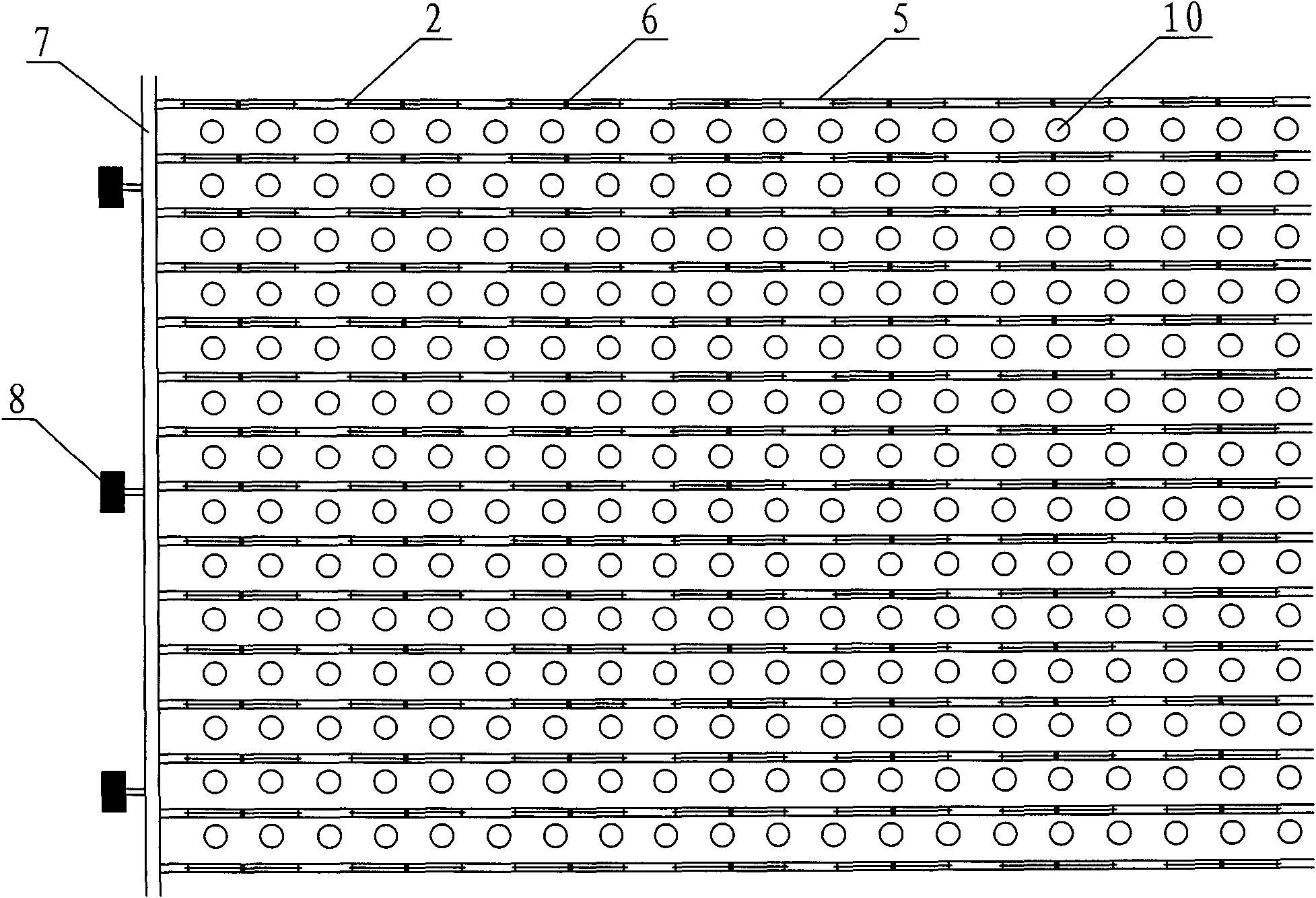

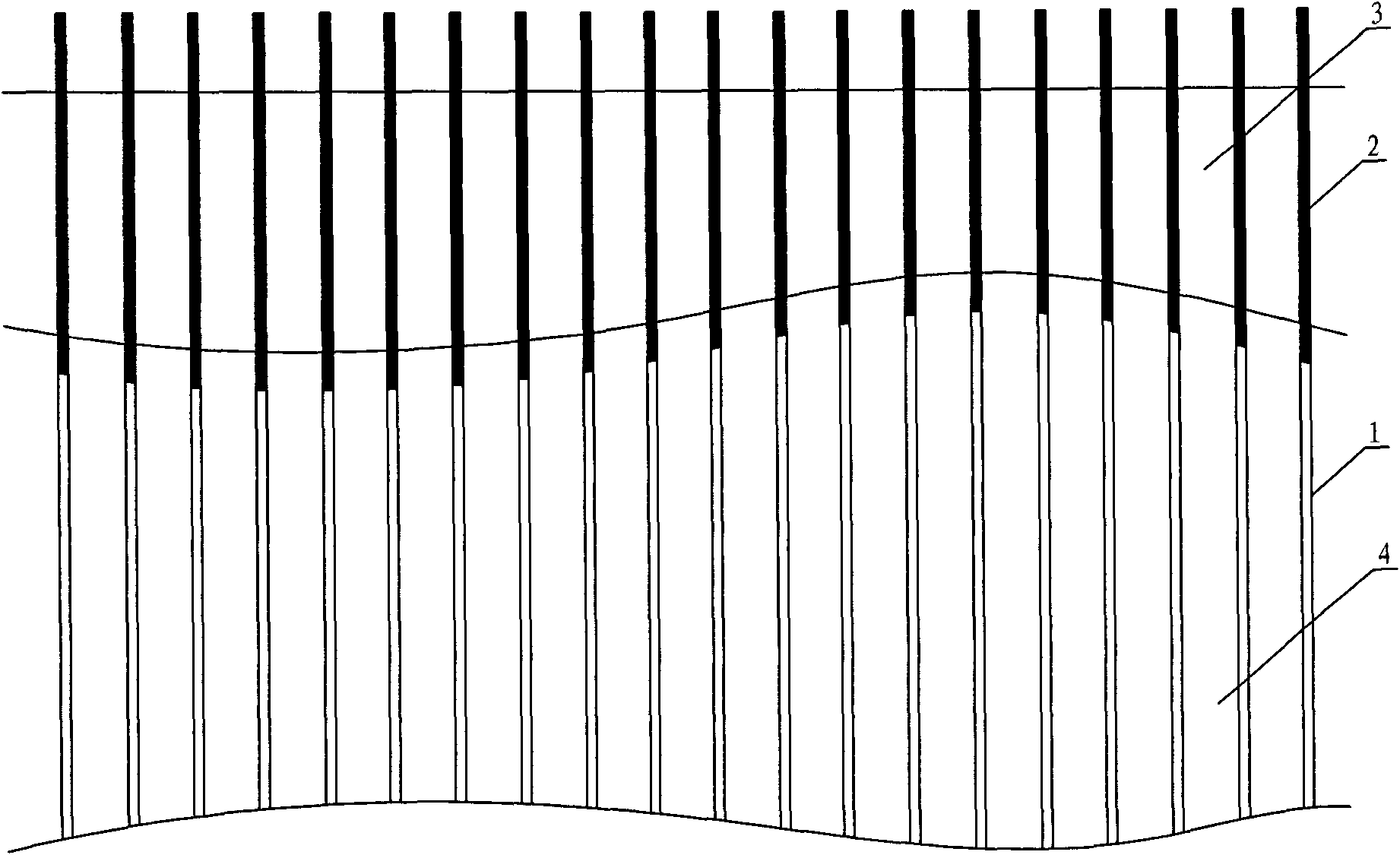

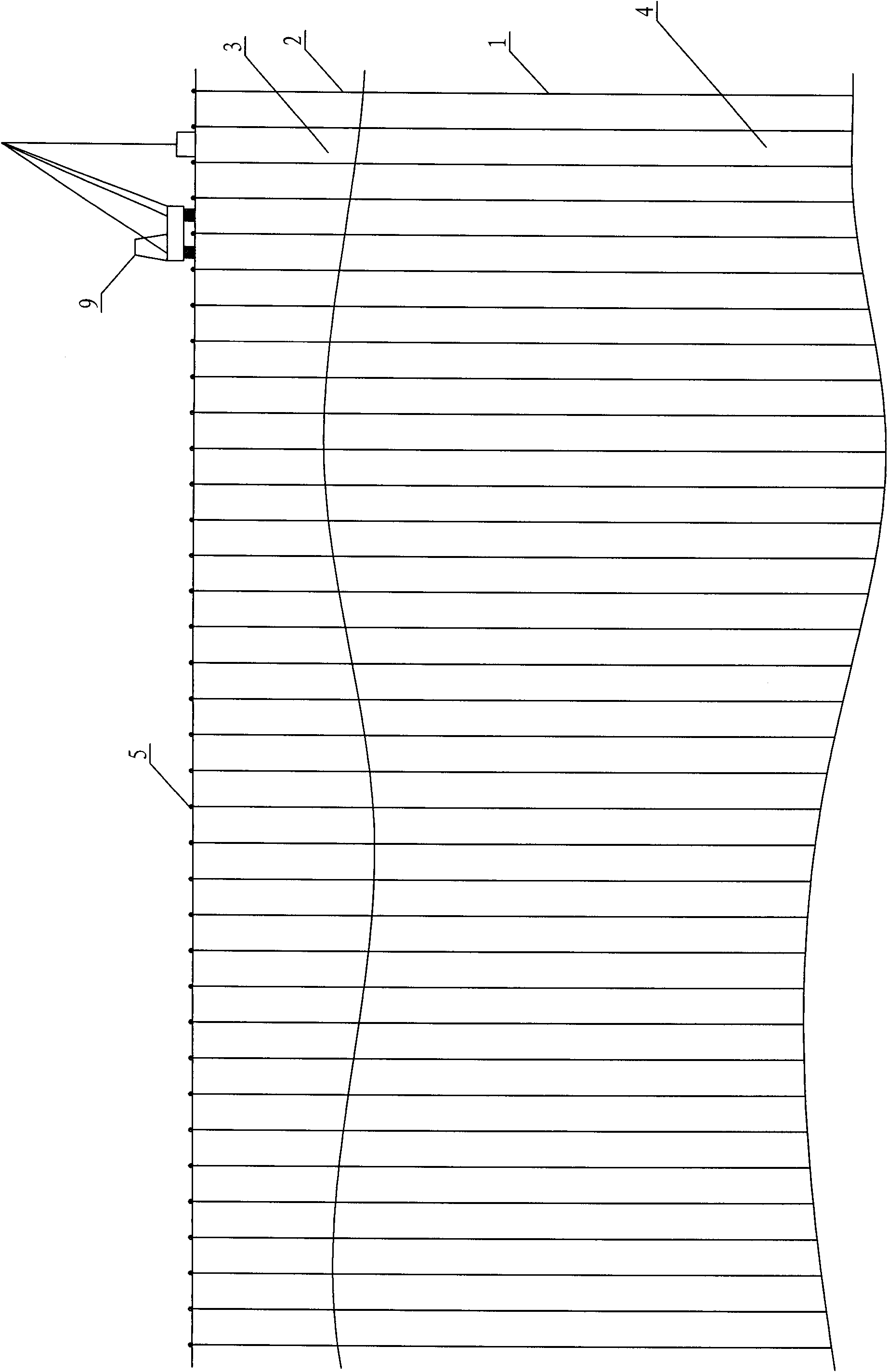

[0026] Such as figure 1 , figure 2 and image 3 Shown, the detailed construction steps of the vacuum dynamic compaction synchronous method of the present invention:

[0027] (1) Arrangement of drainage plate piles, which can be arranged in square and plum blossoms, with a spacing of 0.8-1.4m, determined according to the project situation;

[0028] (2) Determine the depth of the drainage board and the sealing length of the drainage board through exploration. Tanmo takes a square grid as a unit, and the unit width depends on the complexity of the geological conditions of the site. The average value of the thickness of the permeable and air-permeable soil layer 3 at the four corners of the square grid is used as the thickness of the permeable and air-permeable soil layer of the unit. The depth of drainage board 1 is generally set to the bottom of soft soil layer 4. When there is a permeable layer at the lower part of the soft soil layer, there must be a distance of 1m between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com