Scroll compressor

A scroll compressor and scroll technology, applied in the field of scroll compressors, can solve problems such as overcompression and loss increase, and achieve the effect of preventing overcompression and reducing overpressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

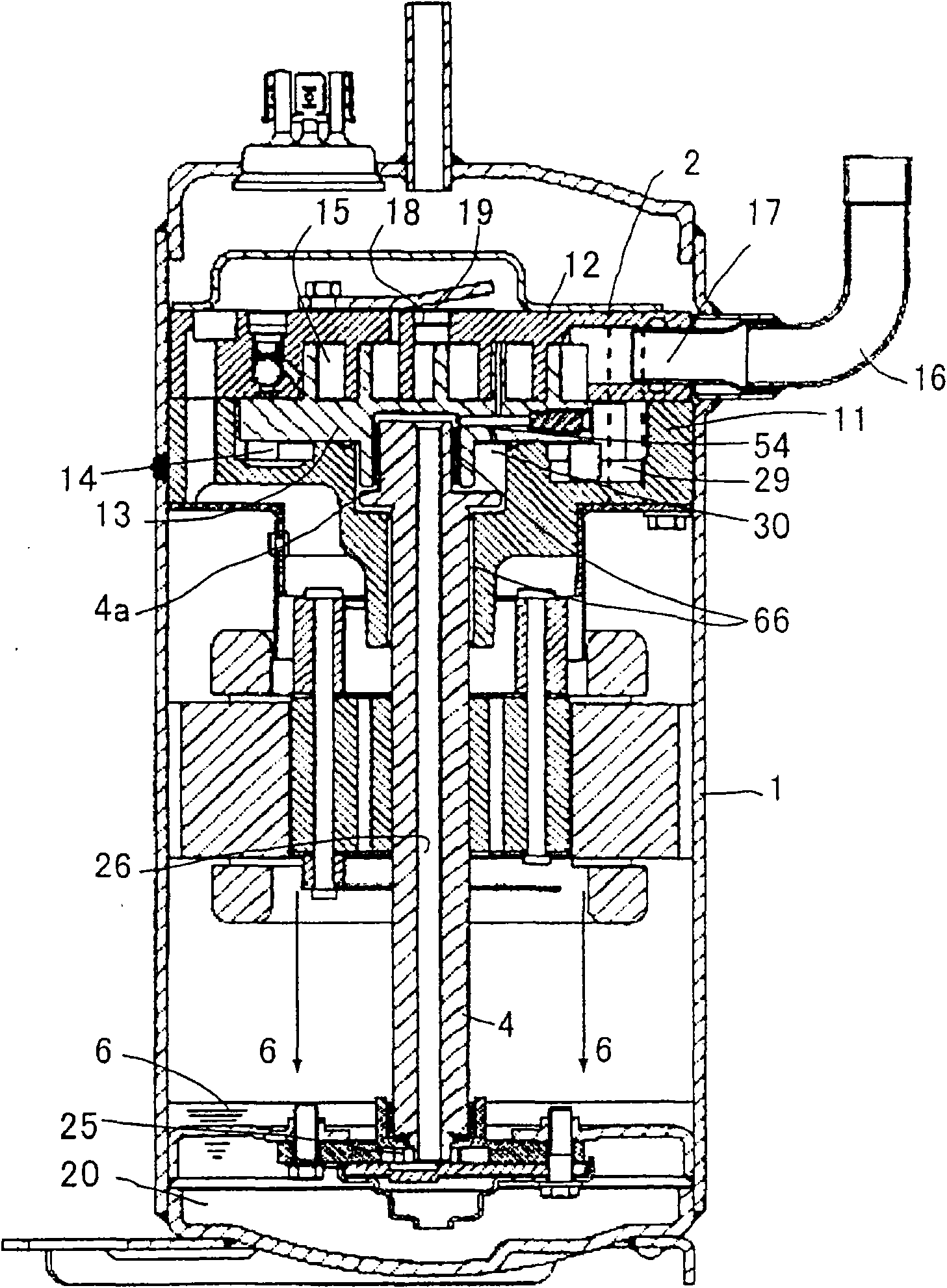

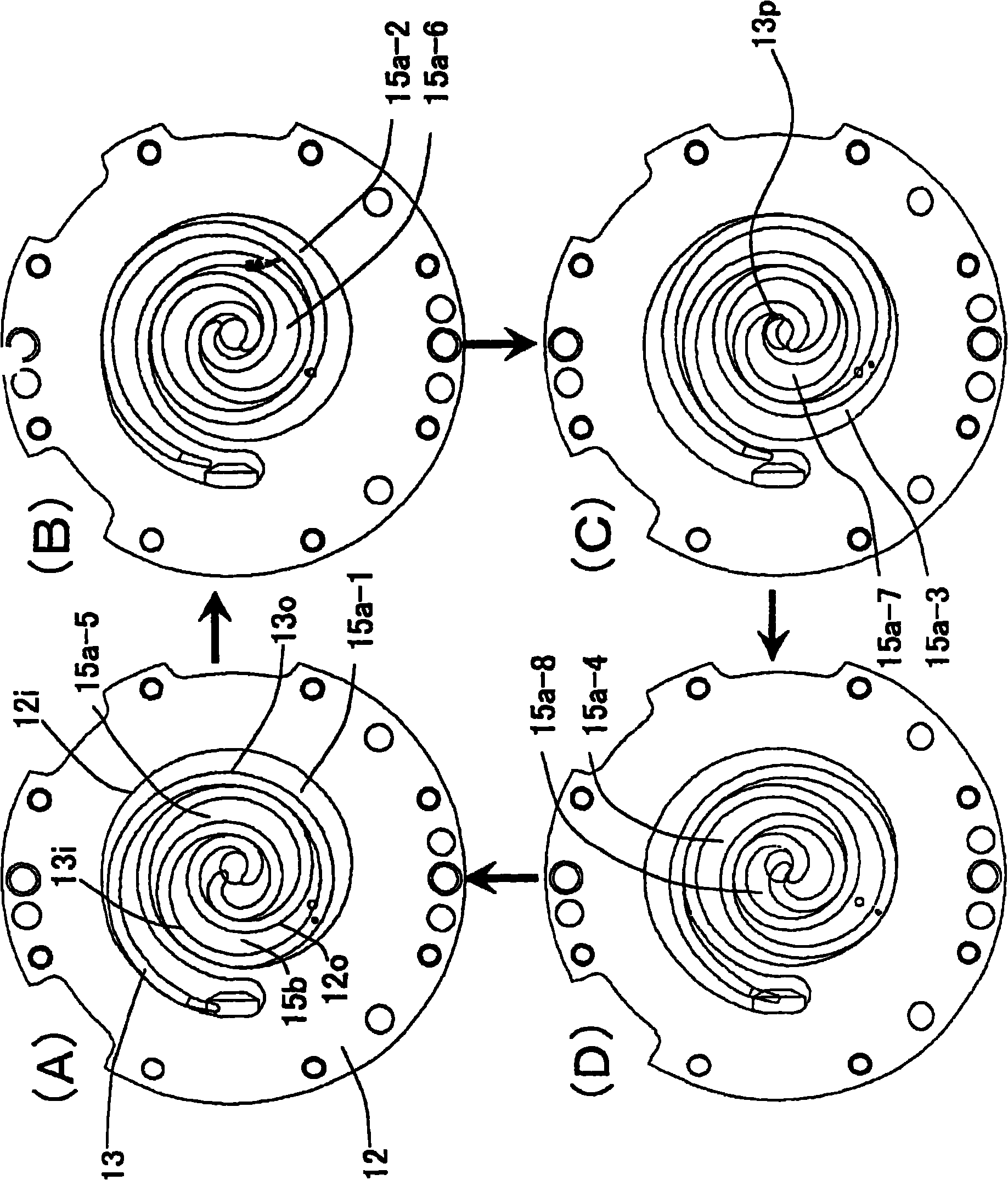

[0031] figure 1 It is a longitudinal sectional view of the scroll compressor in Embodiment 1 of the present invention. The operation and function of the scroll compression chamber will be described below.

[0032] Such as figure 1 As shown, the scroll compressor of the present invention is the main bearing part 11 of the crankshaft 4 fixed in the airtight container 1 by means of welding or heating, inserting, etc., and the fixed scroll fixed on the main bearing part 11 with screws 12, the orbiting scroll 13 engaged with the fixed scroll 12 is sandwiched to form a scroll compression mechanism 2. Between the orbiting scroll 13 and the main bearing member 11, there is provided a rotation restricting structure 14 formed of an Oldham ring or the like that prevents the orbiting scroll 13 from rotating and guides its movement along a circular orbit. By relying on the eccentric shaft portion 4a located at the upper end of the crankshaft 4 to drive the orbiting scroll 13 to rotate...

Embodiment 2

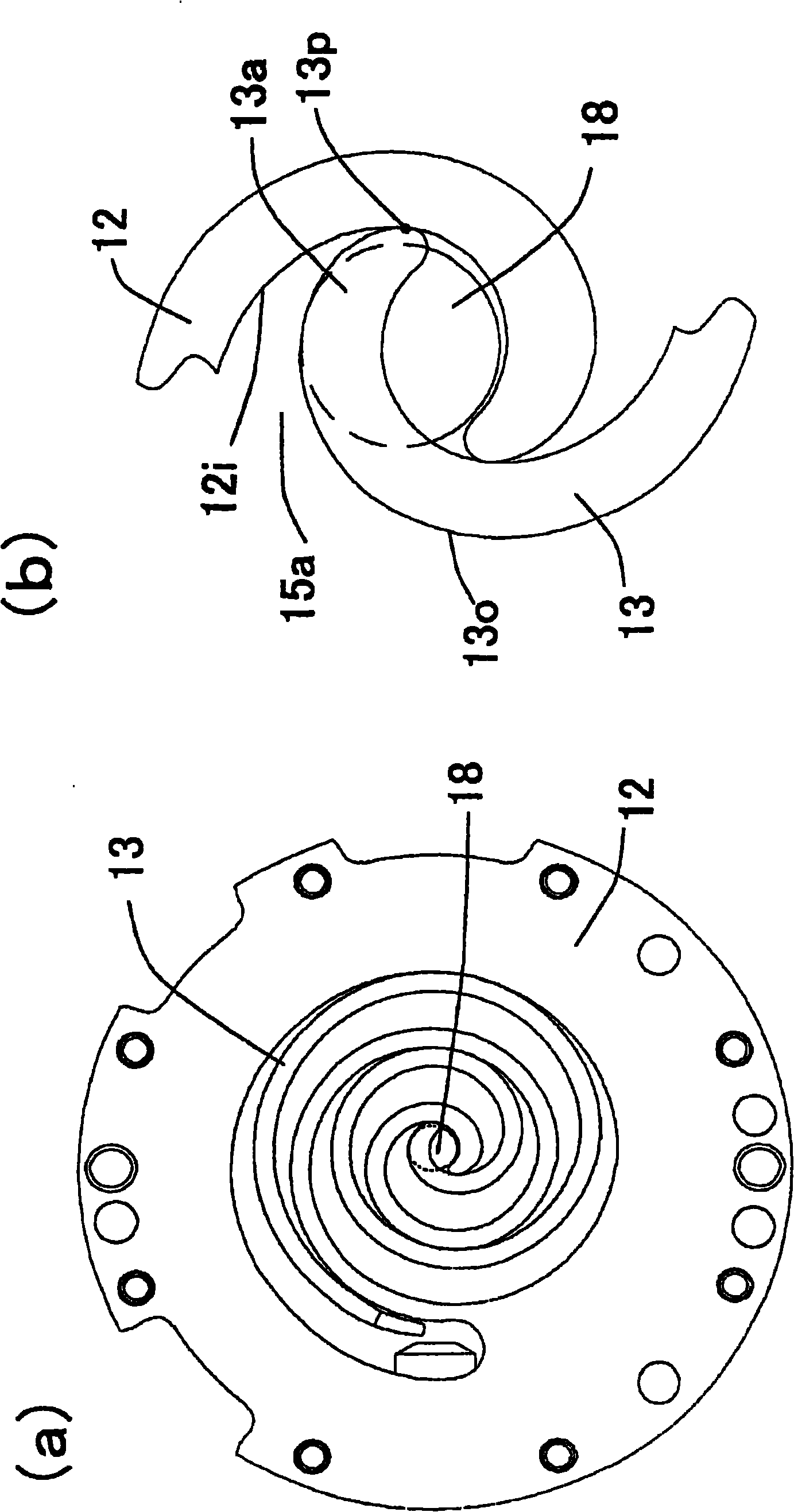

[0045] Figure 4 (a) is a cross-sectional view of the compression mechanism 2 of the scroll compressor according to Embodiment 2 of the present invention, showing that the point 13p corresponding to the wrap start angle of the wrap tooth outer wall 13o of the orbiting scroll 13 is about to start from the fixed scroll The state before the wrap inner wall 12i of the orbiting disk 12 separates and immediately before the concave portion 58 opens into the first compression chamber 15a. Figure 4 (b) is a partially enlarged view of the vicinity of the discharge port 18 . exist Figure 4 neutralize image 3 Only the same symbols are used for the same structure in , and the description is omitted here.

[0046] In the scroll compressor of this embodiment, as Figure 4 As shown in (b), a concave portion 58 communicating with the discharge port 18 is formed on the fixed scroll 12, and a point 13p corresponding to the wrap start angle of the wrap tooth outer wall 13o of the orbiting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com