Flat plate type heat dissipation structure with high heat dissipation effect and manufacturing method thereof

A technology of heat dissipation structure and manufacturing method, which is applied to heat exchange equipment, indirect heat exchangers, metal extrusion dies, etc., to achieve the effect of increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

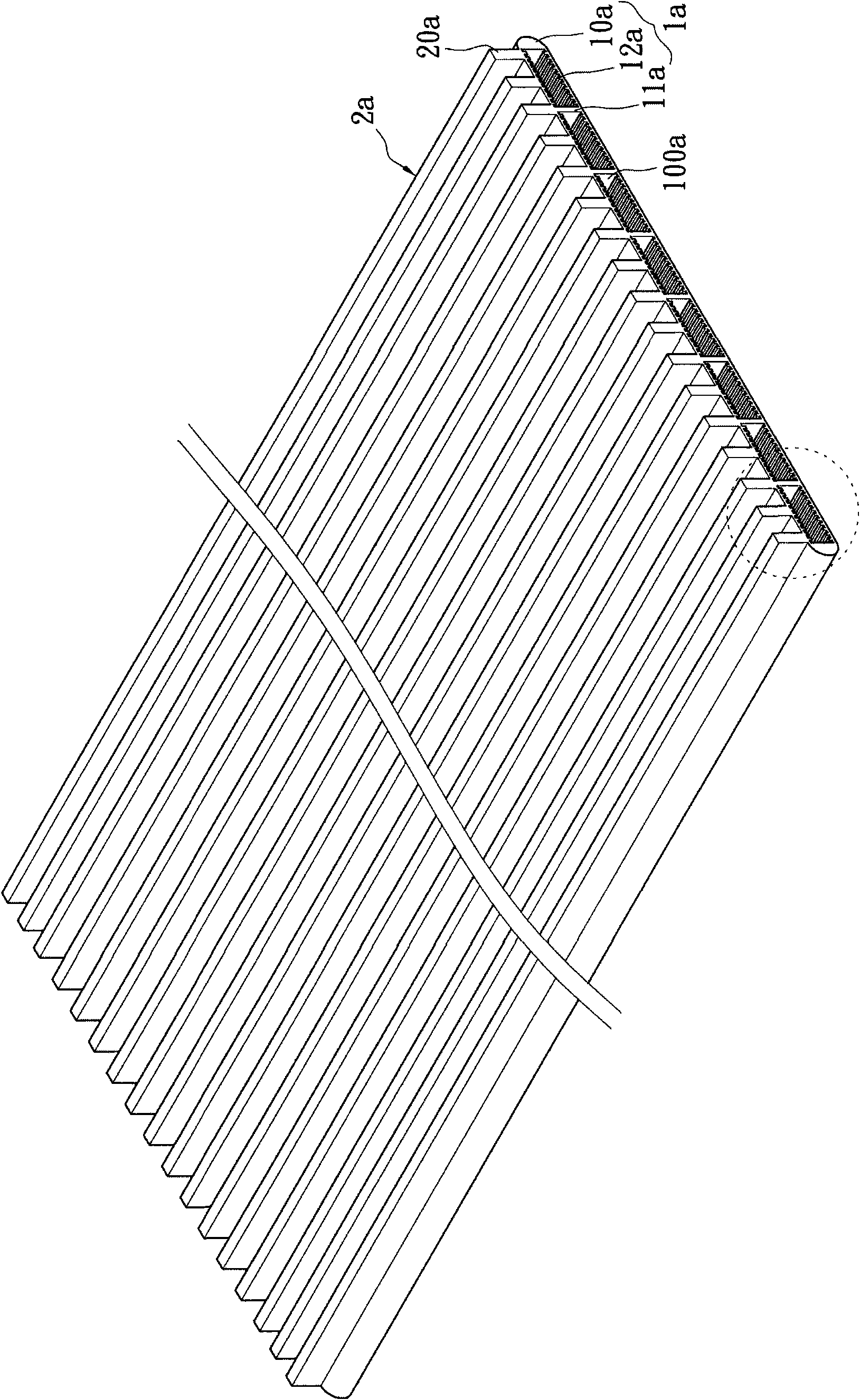

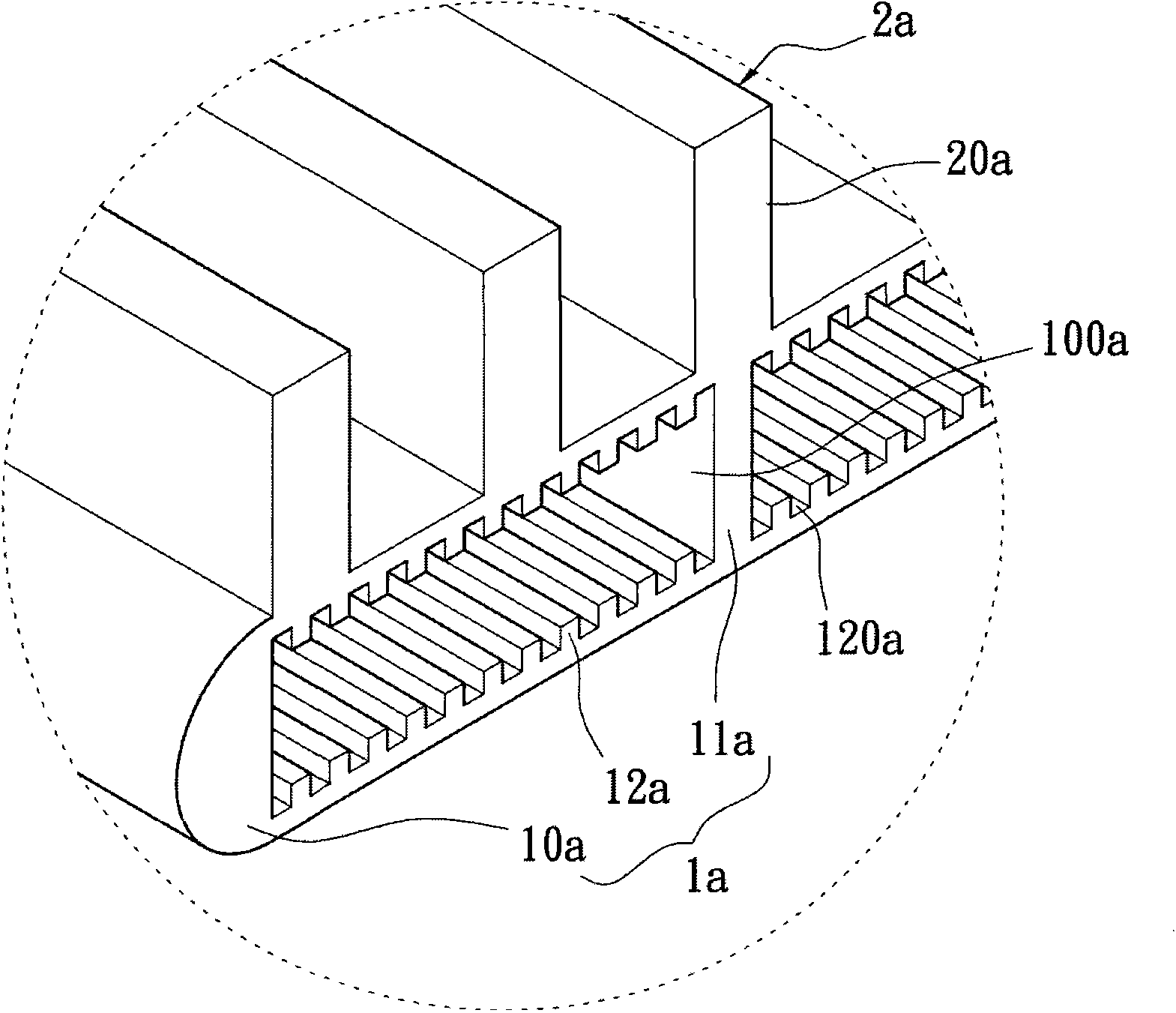

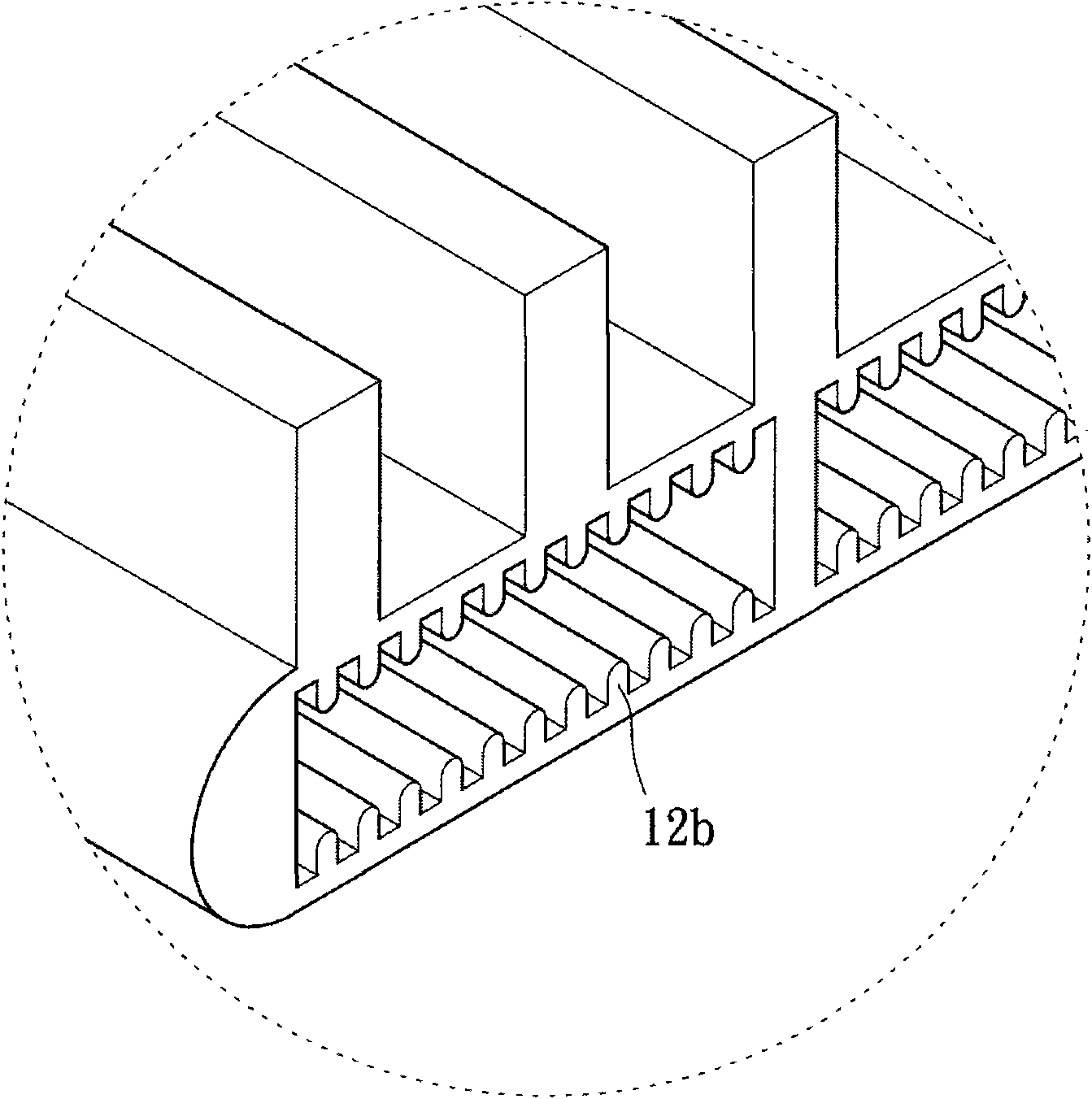

[0084] see Figure 1A to Figure 1B shown, where Figure 1A It is a three-dimensional schematic diagram of the first embodiment of the flat heat dissipation structure with high heat dissipation effect of the present invention; Figure 1B It is a partially enlarged view of the first embodiment of the flat plate heat dissipation structure with high heat dissipation effect of the present invention ( Figure 1A partial enlarged view). It can be seen from the above figures that the first embodiment of the present invention provides a flat heat dissipation structure with high heat dissipation effect, which includes: a first heat dissipation unit 1a and a second heat dissipation unit 2a.

[0085] Wherein, the first heat dissipation unit 1a has a vacuumized and closed hollow heat dissipation body 10a ( Figure 1A The front and rear ends of the hollow heat dissipation body 10a have been cut), a plurality of support plates 11a integrally formed in the hollow heat dissipation body 10a to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com