Mask knife edge moving device of photo-etching machine

A technology for mobile devices and lithography machines, which is applied in the field of lithography machines, can solve problems such as lack of equipment, and achieve the effect of improving flexibility and improving uniformity of illumination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

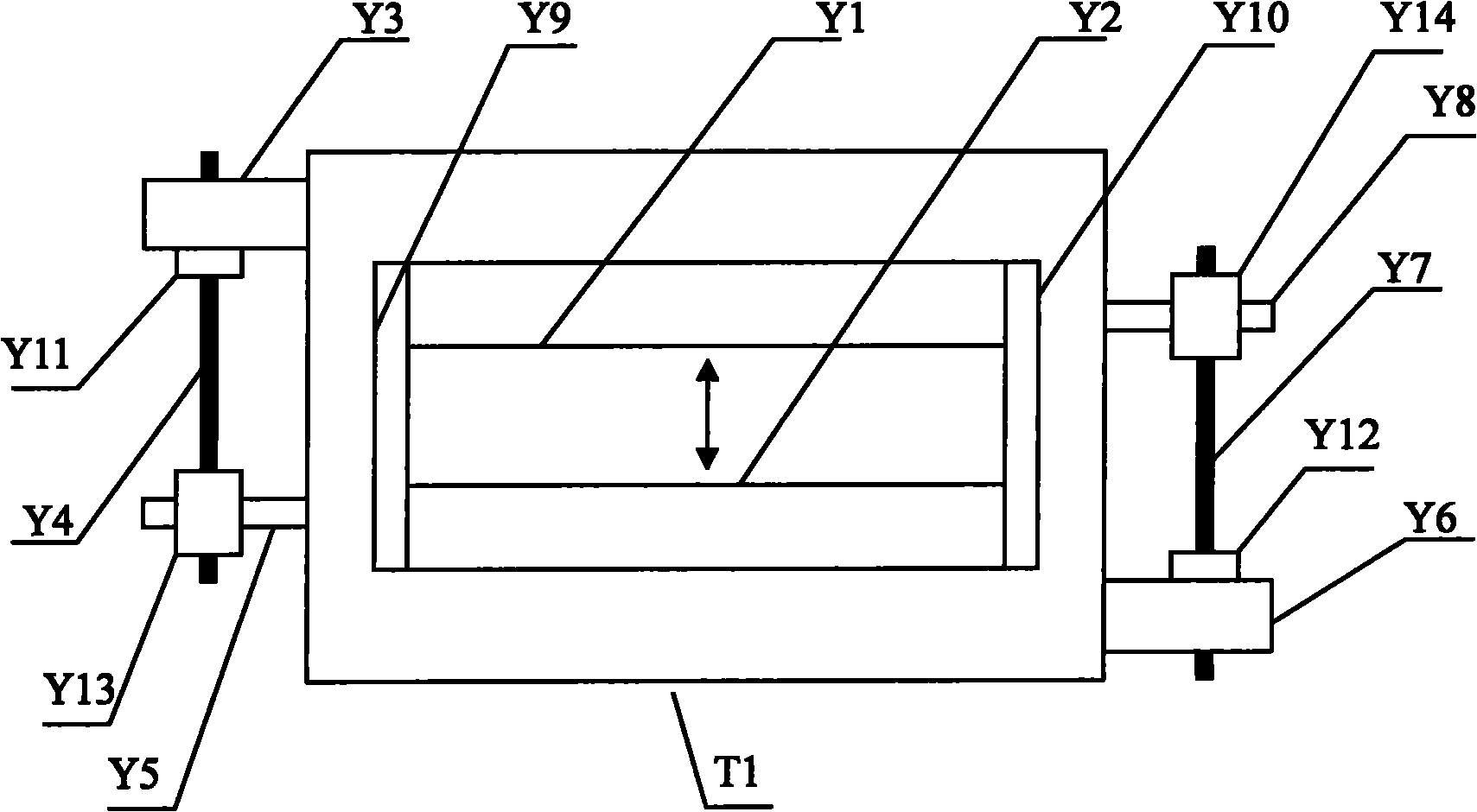

[0009] Such as figure 1 As shown, in the embodiment of the present invention, the Y-direction mask blade moving device is composed of upper and lower blade clamping parts. The Y-up blade clamp part is composed of blade clamp Y1, precision ball screw Y7, screw nut Y14, driving rod Y8, motor Y6, coupling Y12, and grating Y10.

[0010] The Y-down blade clamp part is composed of blade clamp Y2, precision ball screw Y4, screw nut Y13, driving rod Y5, motor Y3, coupling Y11, and grating Y9.

[0011] The Y-up blade clamp Y1 is installed on the driving rod Y8, the motor Y6 is connected with one end of the precision ball screw Y7 through the coupling Y12, the other end of the precision ball screw Y7 is connected with the screw nut Y14, and the screw nut Y14 is connected with the screw nut Y14. Drive bar Y8 links to each other. The detection grating Y10 is installed on the right side of the blade holder Y1 and is perpendicular to the blade holder Y1. When the blade clamp Y1 needs to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com