Air disinfection machine

An air sterilizer and fan technology, applied in air quality improvement, mechanical equipment, air flow control components, etc., can solve the problems of easy aging of plastic parts, uneven light intensity, sterilization dead angle affecting sterilization effect, etc., to improve the uniformity of light. , Improve the sterilization effect, eliminate the effect of lighting dead angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

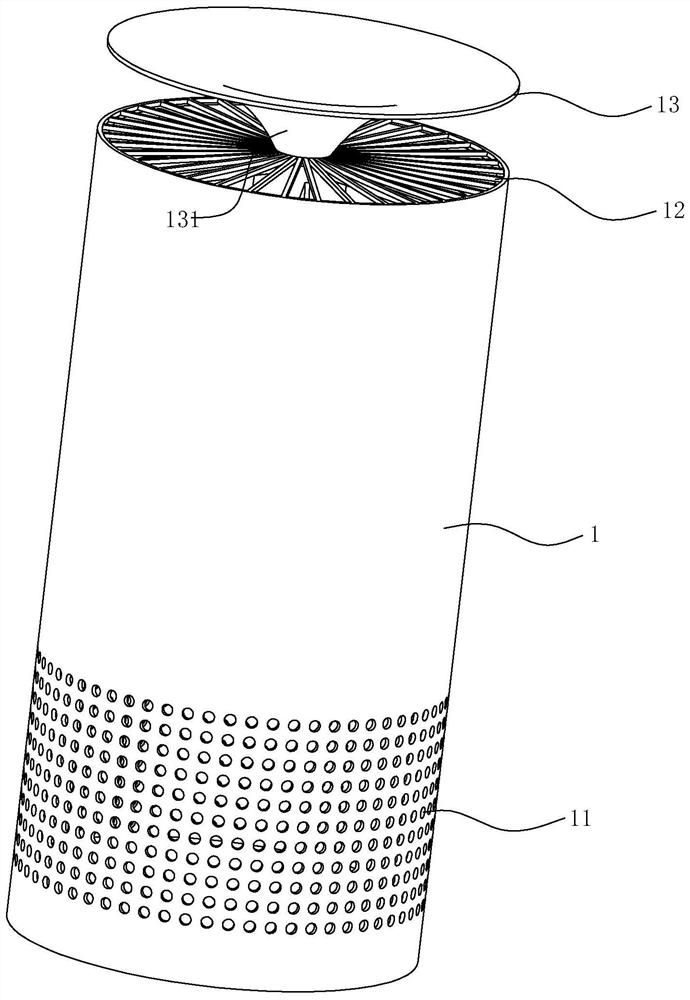

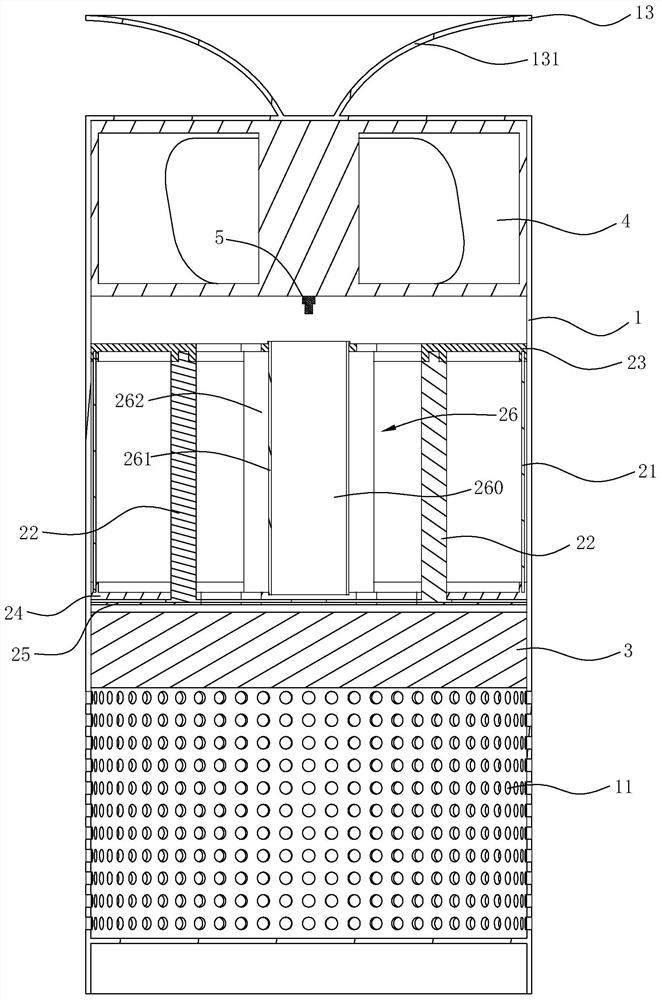

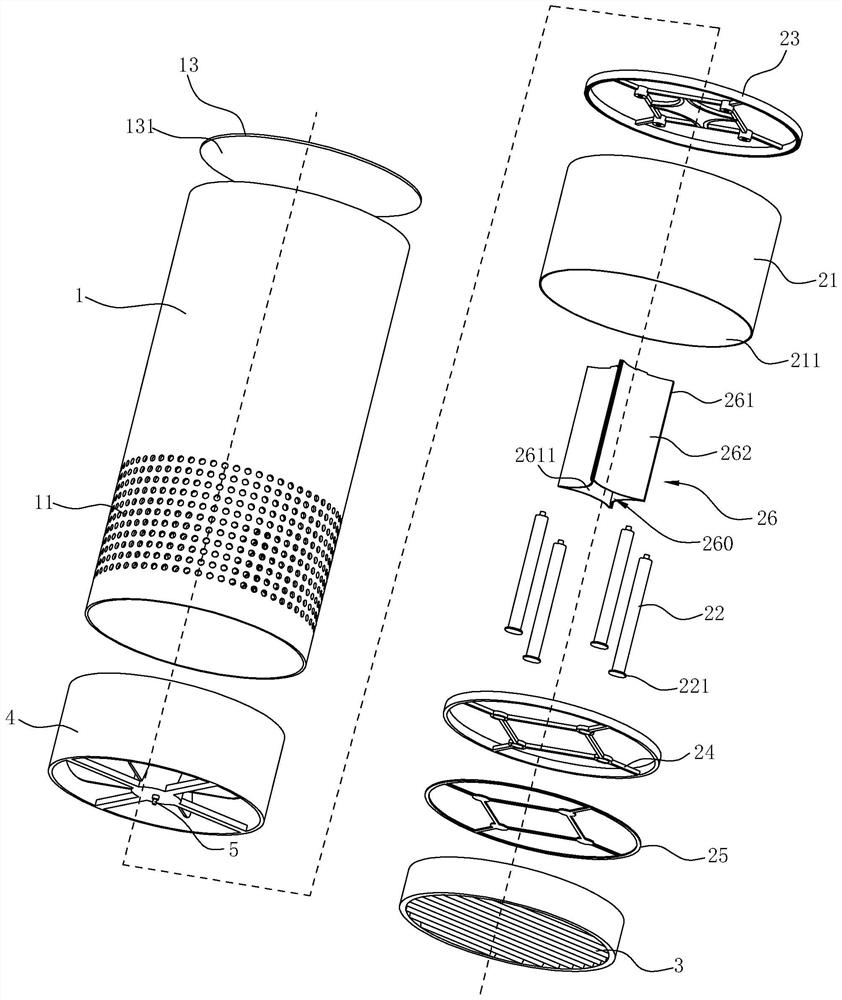

[0022] like Figures 1 to 4 As shown, the air sterilizer of this embodiment includes a casing 1 and a germicidal lamp assembly 2 arranged in the casing 1. The outer peripheral wall of the lower part of the casing 1 has several air inlets 11 and the top wall has air outlets 12. The germicidal lamp assembly 2 is located between the air inlet 11 and the air outlet 12 . The housing 1 of this embodiment is further provided with a filter assembly 3 for filtering particulate matter, and the filter assembly 3 is located upstream of the germicidal lamp assembly 2 . The casing 1 is provided with a fan assembly 4 for sucking indoor air into the casing 1 and discharging the sterilized air, the fan assembly 4 is arranged downstream of the germicidal lamp assembly 2, and the air inlet of the fan assembly 4 is arranged. Detection sensor 5 for detecting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com