Friction stir welding method for stirring pin and shaft shoulder during differential speed rotation

A friction stir and welding method technology, applied in welding equipment, non-electric welding equipment, metal processing equipment and other directions, can solve the problems of huge energy consumption, large forward resistance, strict clamping requirements, etc., to improve production efficiency and welding speed. The effect of speeding up and reducing set-up requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

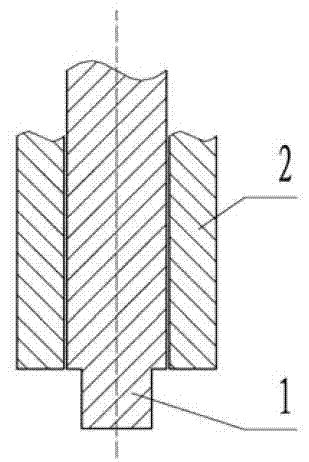

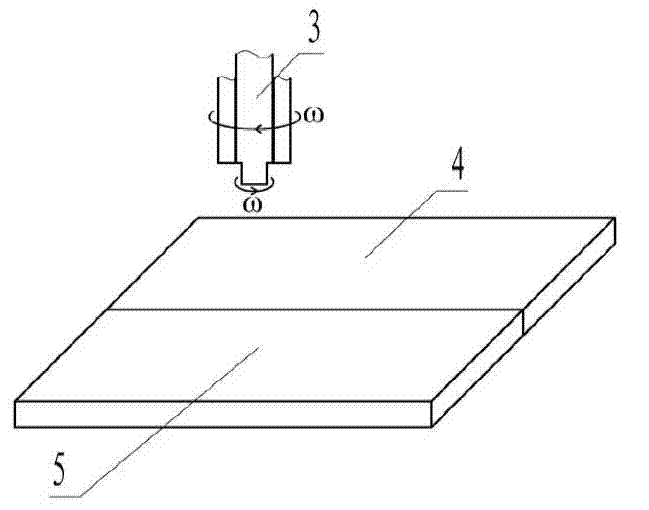

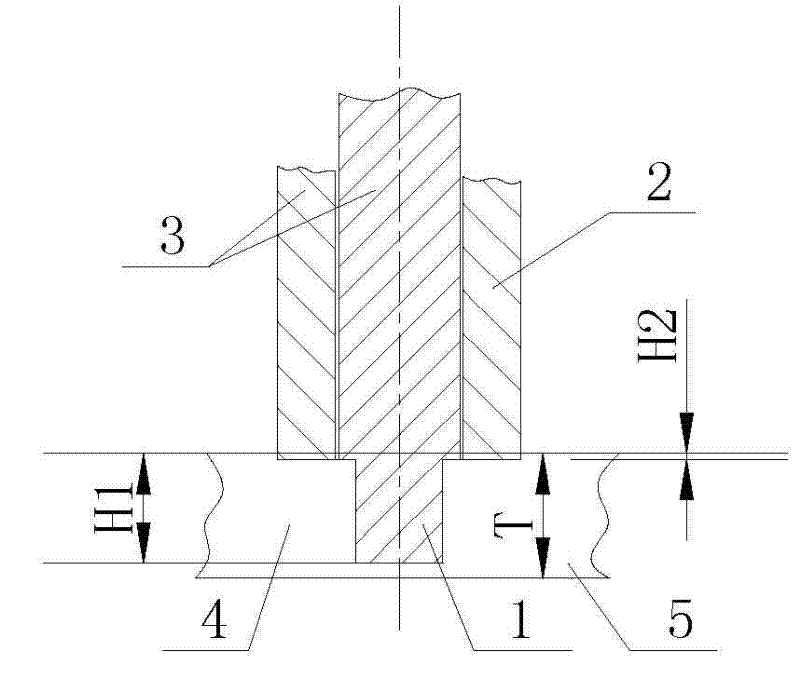

[0014] Specific implementation mode one: as Figure 1~3 As shown, a friction stir welding method in which the stirring needle and the shaft shoulder rotate at a differential speed described in this embodiment is realized according to the following steps:

[0015] Step 1. Set the first workpiece 4 to be welded and the second workpiece 5 to be welded butt-connected and both are located on the same horizontal plane (that is, the first workpiece to be welded 4 and the second workpiece to be welded 5 are paired), and clamped on the On the workbench; the first workpiece to be welded 4 and the second workpiece to be welded 5 are plates;

[0016] Step 2, the stirring needle 1 of the stirring head 3 is rotated at a speed of 3000 to 30000 rpm Into the part to be welded (that is, the butt surface of the first workpiece 4 to be welded and the second workpiece 5 to be welded); the rotation speed of the shoulder 2 of the stirring head 3 Lower than the rotation speed of Stirring Needle 1...

specific Embodiment approach 2

[0018] Specific embodiment two: In step two of this embodiment, the rotational speed of the shaft shoulder 2 100-800 rpm. The rotation speed of the shoulder 2 can be selected according to the specific conditions of the first workpiece 4 and the second workpiece 5 to be welded, so as to reduce the lowering and forward resistance of the stirring head 3 . Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Specific embodiment three: In step two of this embodiment, the piercing speed of the stirring head 3 is 2-4 mm / min. The penetration speed of the stirring head 3 can be selected according to the specific conditions of the first workpiece 4 to be welded and the second workpiece 5 to be welded, so that the stirring head 3 can easily penetrate into the workpiece to be welded. Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com