Detaching tool for embedded nuts of plane spoiler and detaching method

A disassembly tool and embedded technology, which is applied in the field of disassembly tools and disassembly of embedded nuts of aircraft spoilers, can solve the problems of honeycomb sandwich structure skin, spoiler debonding, tool damage, etc., and achieve improved fatigue resistance Performance, not easy to disengage, and the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

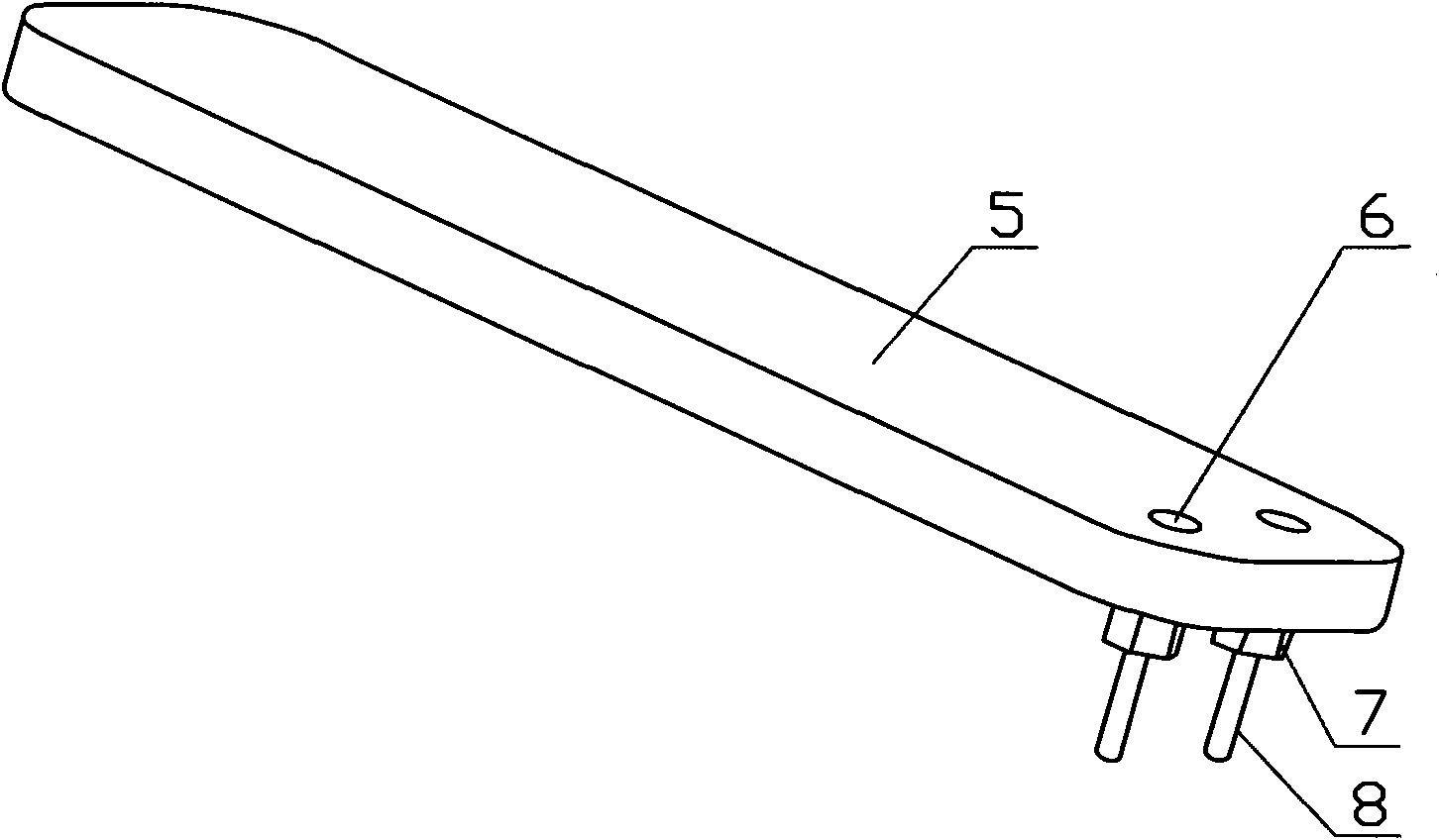

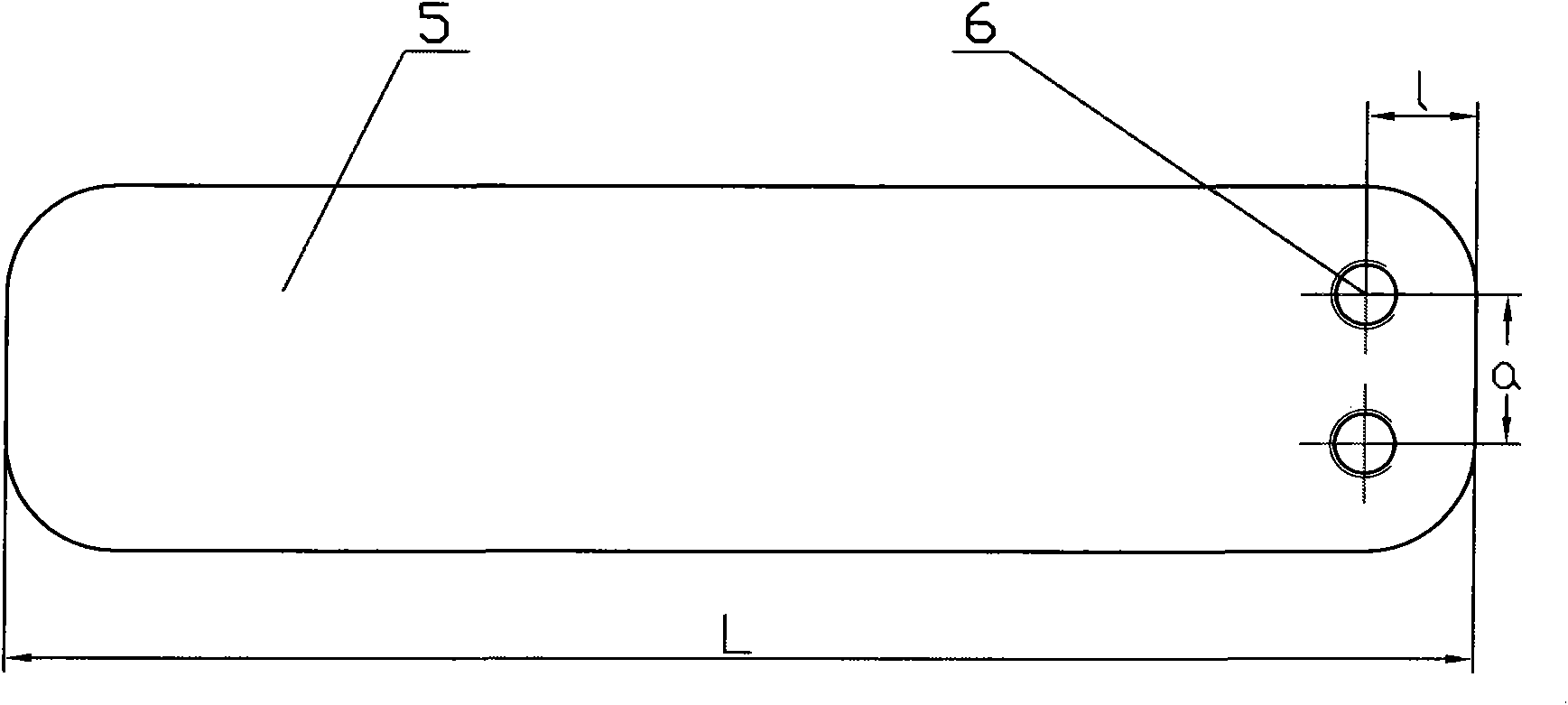

[0025] Refer to the instructions attached figure 2 , An aircraft spoiler embedded nut removal tool, which includes a plate-shaped base 5 and a pair of removal members with outhanging rods 8 arranged at the front end of the base perpendicular to the surface of the base, wherein two The pitch a of the outriggers is 0.52 to 0.56 inches, the length h of the outriggers is 0.36 to 0.40 inches, and the diameter d is 0.094 inches.

[0026] Preferably, the distance between the two outriggers is 0.55 inches, and the length of the outriggers is 0.38 inches.

[0027] In order to meet the requirements of use and make the structure of the base as compact as possible, the base is selected from materials with a yield strength greater than 60Ksi and a tensile strength greater than 70Ksi, and the outstretching rod is selected from high-speed steel. Of course, the base is mainly held by hand. The feeling of holding is very important and the size should not be too small. Therefore, the material of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com