Biochemical exterior drainage decoloring agent and preparation method thereof

A decolorizing agent and biochemical technology, applied in metallurgical wastewater treatment, adsorption water/sewage treatment, etc., can solve the problems of large-scale application of activated carbon due to cost constraints, easy decomposition of flocculated substances, and high price of activated carbon, and achieve excellent adsorption and enhanced Effect of pore-forming reaction and improvement of adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

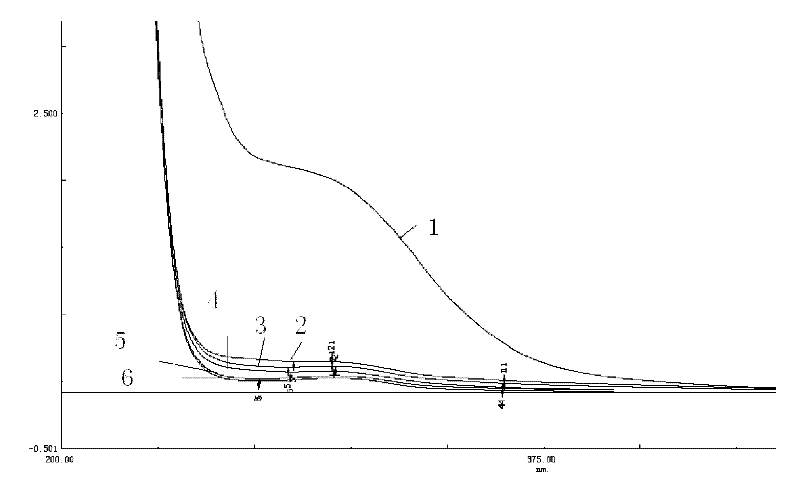

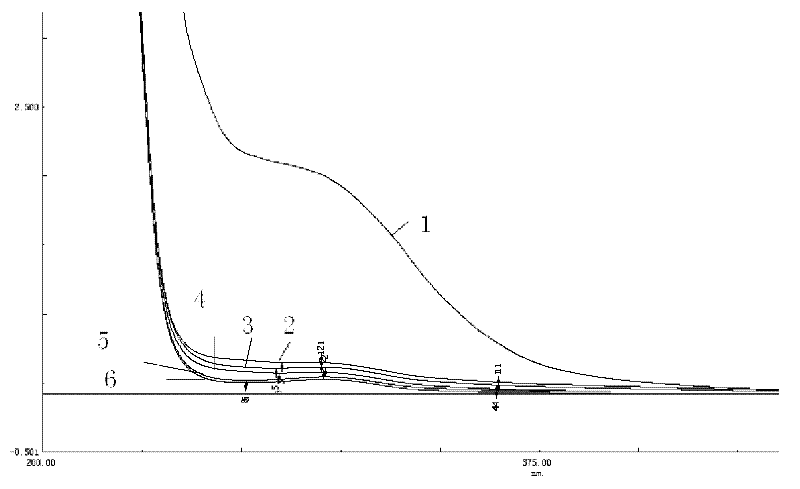

Image

Examples

Embodiment 1

[0024] 200 parts by weight of semi-coke particles with a particle diameter of 18mm, K 2 CO 3 1 part by weight, Ca(OH) 2 5 parts by weight are placed in a closed reactor for heating, and the pressure inside the reactor is controlled to be 4Mpa. When the closed reactor is heated to 800°C, start to feed CO 2 Gas, the gas flow rate is 10L / min per kg of semi-coke particles, and CO is fed at a temperature of 800-830°C 2 10 min, then stop CO 2 The gas input is stopped at the same time and the reactor is heated, the closed reactor is naturally cooled to room temperature, and finally the reaction product in the closed reactor is taken out, that is, the decolorizing agent 2 of the present invention.

Embodiment 2

[0026] 200 parts by weight of semi-coke particles with a particle diameter of 3mm, 3 parts by weight of sodium carbonate, Ca(OH) 2 3 parts by weight are placed in a closed reactor for heating, and the pressure inside the reactor is controlled to be 3Mpa. When the closed reactor is heated to 700°C, start to introduce CO 2 Gas, the gas flow rate is 8L / min per kg of semi-coke particles, and CO is fed at a temperature of 700-730°C 2 20 min, then stop CO 2 Gas input stops the reactor simultaneously and heats up, makes airtight reactor cool down to room temperature naturally, all adopts N during described heating up and cooling. 2 Gas protection, and finally take out the reaction product in the closed reactor, which is the decolorizing agent 2 of the present invention.

Embodiment 3

[0028] 200 parts by weight of semi-coke particles with a particle diameter of 13mm, K 2 CO 3 3 parts by weight are placed in a closed reactor for heating, and the pressure inside the reactor is controlled to 1Mpa. When the closed reactor is heated to 900°C, start to introduce CO 2 Gas, the gas flow rate is 5L / min per kg of semi-coke particles, and CO is fed at a temperature of 900-930°C 2 40 min, then stop CO 2 The gas input is stopped at the same time and the reactor is heated, the closed reactor is naturally cooled to room temperature, and finally the reaction product in the closed reactor is taken out, that is, the decolorizing agent 3 of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com