Low-true-density kaolin rubber reinforcing filler and preparation method thereof

A technology of reinforcing filler and high density, applied in the field of rubber filler, can solve the problems of high density and poor reinforcing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

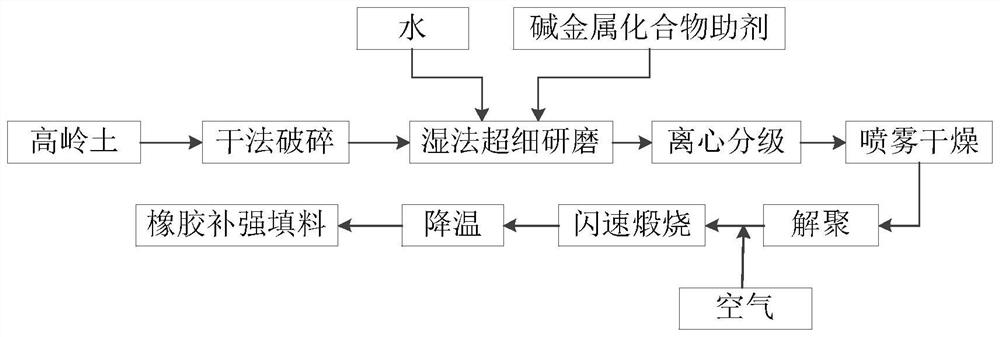

[0024] Such as figure 1 As shown, the preparation method of the low true density kaolin rubber reinforcing filler of the present embodiment comprises the following steps:

[0025] Using kaolin as raw material, kaolin is dry crushed to obtain coarse material, which is added with water and alkali metal compound additives for wet ultrafine grinding, and then centrifugally classified to obtain ultrafine slurry. Kaolin less than or equal to 2μm accounts for more than 95%;

[0026] The ultra-fine slurry is spray-dried and depolymerized to obtain fine material particles;

[0027] The fine material particles are mixed with air to obtain suspended matter, and the suspended matter is sprayed into the calcining kiln by jet flow for flash calcination, and the temperature is lowered to obtain low true density kaolin rubber reinforcing filler;

[0028] Kaolin adopts organic matter content of 0.1% to 30%, K 2 O and Na 2 O is kaolin with a total mass content of 0.1% to 1%.

[0029] The p...

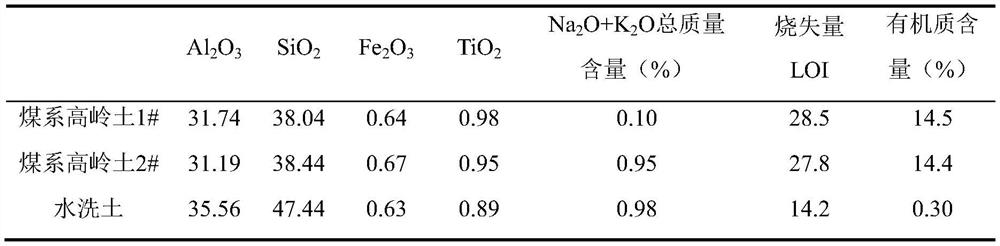

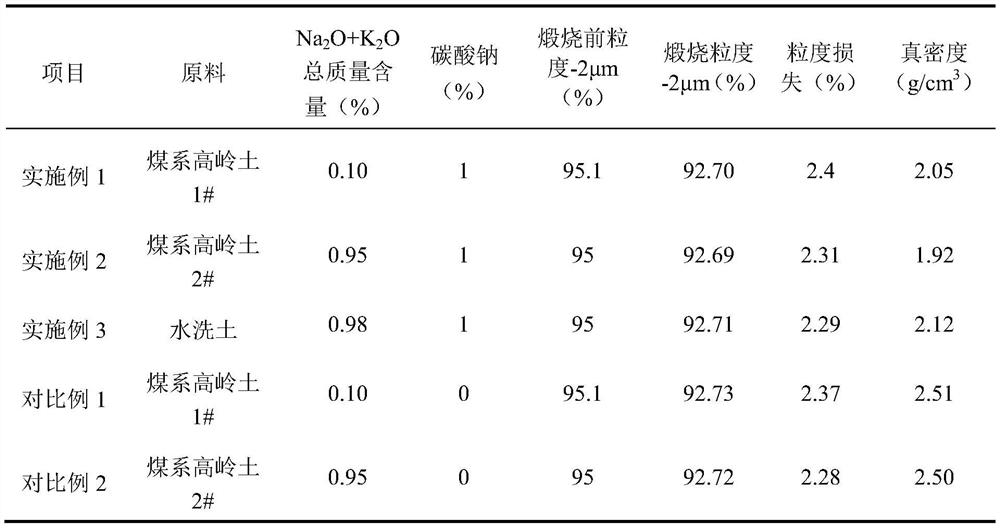

Embodiment 1

[0044] Coal-based kaolin 1# is used as raw material, and coal-based kaolin 1# is dry crushed to obtain coarse material. The coarse material is added with water, 1% sodium carbonate and 6% sodium hexametaphosphate for wet ultra-fine grinding, and then centrifuged Superfine slurry is obtained by classification, and the proportion of kaolin less than or equal to 2 μm in the ultrafine slurry is more than 95%;

[0045] The ultra-fine slurry is spray-dried and depolymerized to obtain fine material particles;

[0046] Mix the fine material particles with air to obtain a suspension, and the content of kaolin in the suspension is 5kg / m 3 , the suspension is sprayed into the tubular calcination kiln with a jet flow rate of 20m / s for flash calcination. The temperature of flash calcination is 1000°C, the time is 0.5s, and the temperature is quickly lowered to below 700°C within 10s after mixing with cold air. , to obtain low true density kaolin rubber reinforcing filler.

Embodiment 2

[0048] The difference from Example 1 is that coal series kaolin 2# is used as raw material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com