Composite catalyst for industrial wastewater treatment by electrolytic oxidation method and preparation method thereof

A technology for composite catalysts and industrial wastewater, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, water/sewage treatment, etc., can solve the problems of easy clustering, low activity, acid and alkali corrosion resistance Poor performance and other problems, to achieve the effect of good fluidization performance, high catalytic activity, uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

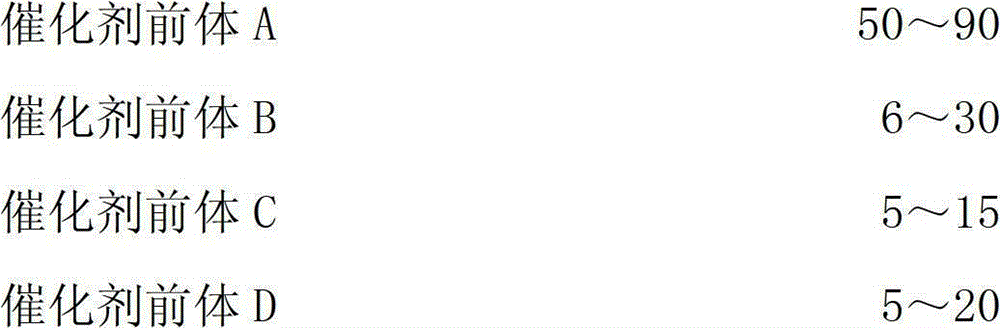

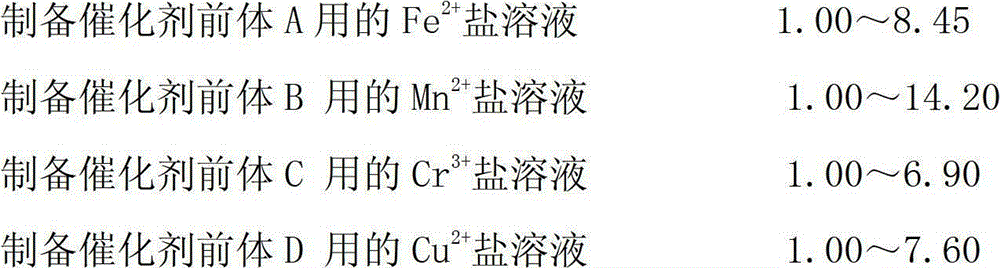

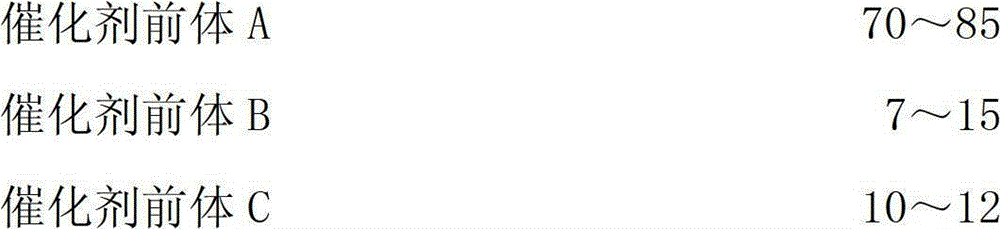

Method used

Image

Examples

Embodiment 1

[0060] Weigh 10g of polystyrene resin pellets, add them into 100ml of chloroform, add them into chloroform, slowly add 50ml of 30%-50% fuming sulfuric acid while stirring at room temperature, then sulfonate in a water bath at 60°C for 180min, and slowly Add absolute ethanol, suction filter, wash 3 times, and then wash with deionized water until there is no SO in the washing liquid 4 2- Check it out, and then dry it with a hair dryer for later use. This step is repeated several times to prepare a sufficient amount of sulfonated polystyrene resin for future use.

[0061] Equipped with Fe with a mass fraction of 8.10% 2+ Add 120ml of salt solution into a 200ml beaker and conduct ion exchange with 20g of sulfonated polystyrene resin at 25°C. The reaction time is 90min, then filter and wash the catalyst precursor for 5 times, place it in an oven and dry at 80°C for 360min to obtain the catalyst precursor A; Equipped with Mn with a mass fraction of 10.92% 2+ Add 120ml of salt so...

Embodiment 2

[0064] After adopting the same steps as in Example 1 to carry out sulfonation to the selected carrier, respectively use Fe with a mass fraction of 5.52% 2+ Salt solution, Mn with a mass fraction of 7.28% 2+ Salt solution, Cr with a mass fraction of 3.28% 3+ Salt solution, Cu with a mass fraction of 4.80% 2+ The salt solution and the sulfonated carrier were ion-exchanged at 20°C. After the reaction, it was detected that Fe in A 2+ The loading amount is 3.3%, Mn in B 2+ The loading amount is 3.4%, Cr in C 3+ The loading amount is 2.9%, Cu in D 2+ The load is 3.3%. The catalyst was prepared in the same steps as in Example 1.

[0065] Using the process parameters of Example 1, the same wastewater as in Example 1 was treated. After treatment, the COD of the effluent was 39 mg / L, and the COD removal rate was 74%.

Embodiment 3

[0067] Using the same steps as in Example 1, after the selected carrier is sulfonated, use the same mass fraction of Fe as in Example 1 2+ , Mn 2+ 、Cr 3+ 、Cu 2+ The salt solution and the sulfonated carrier were ion-exchanged at 45°C, and the reaction time was 900min. After the reaction, it was detected that Fe in A 2+ The loading amount is 7.3%, Mn in B 2+ The loading amount is 5.9%, Cr in C 3+ The loading amount is 7.5%, Cu in D 2+ The loading capacity is 7.2%. The catalyst was prepared in the same steps as in Example 1.

[0068] Using the process parameters of Example 1, the same wastewater as in Example 1 was treated. After treatment, the COD of the effluent was 35 mg / L, and the COD removal rate was 76.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com