High-temperature-hot-water corrosion resisting coating

A technology of high temperature resistance and coating, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of inconvenient construction and high cost of coatings, and achieve the effects of reduced cost, simple coating process, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021]A: Weigh 60 parts (hereinafter referred to as mass) of epoxy-modified silicone resin (SMH-30) and add an appropriate amount of diluent (n-butanol: xylene (mass ratio) = 3: 7) to dilute and stir evenly; B : Add 30 parts of mica iron oxide ash, 10 parts of sericite, 3 parts of talcum powder, stir with a strong electric mixer for 15 minutes at high speed, add 0.3 parts of dispersant (DISPERBYK-142), 0.2 parts of disinfectant during stirring Foaming agent (BYK-066N) to obtain component A; C: weigh 6 parts of polyamide curing agent as component B; D: mix components A and B and stir evenly to obtain the coating composition of the present invention .

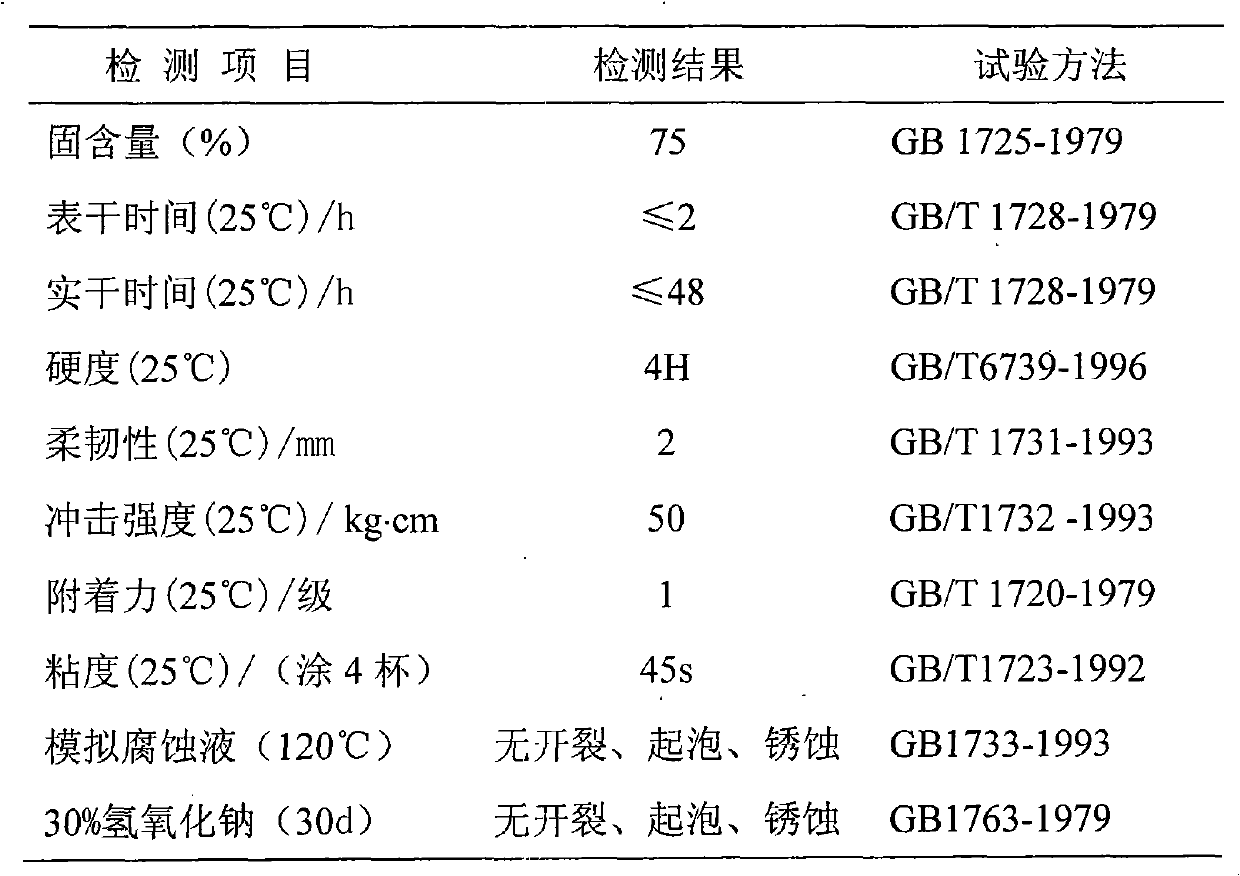

[0022] Use the above-mentioned paint to brush and paint on the steel plate specified in the national standard to obtain a paint film thickness of 120 μm, and cure it at room temperature (10-40°C) for 48 hours to obtain a smooth and hard coating film. The physical and mechanical properties of the test coating film are shown in Tab...

Embodiment 2

[0025] A: Weigh 60 parts (hereinafter referred to as mass) of epoxy-modified silicone resin (SMH-30), add an appropriate amount of diluent (n-butanol: xylene (mass ratio) = 3:7) to dilute and stir evenly; B: Add 30 parts of mica iron oxide ash, 10 parts of sericite, 3 parts of talcum powder, stir with a powerful electric mixer at high speed for 15 minutes, add 0.3 parts of dispersant (DISPERBYK-142), 0.2 parts of Defoamer (BYK-066N) to obtain component A; C: Weigh 3 parts of T31 curing agent as component B; D: Mix components A and B and stir evenly with a glass rod at a low speed to obtain the present invention coating composition.

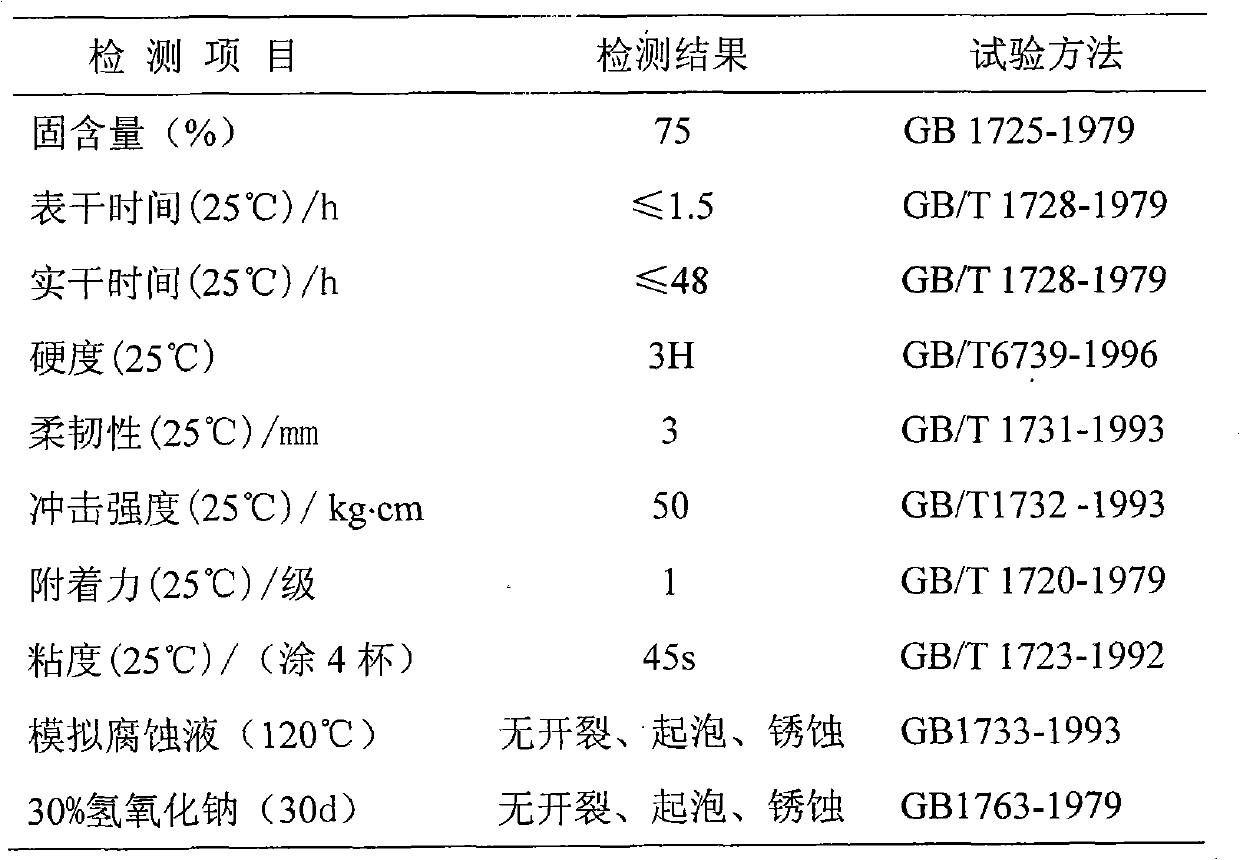

[0026] Use the above-mentioned paint to brush and paint on the steel plate specified in the national standard to obtain a paint film thickness of 120 μm, and cure it at room temperature (0-10°C) for 48 hours to obtain a smooth and hard film. The physical and mechanical properties of the test film are as follows:

[0027]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com