Method for preparing magnesium alloy bar with superhigh intensity by powerful deformation

A magnesium alloy, ultra-high-strength technology, applied in the deformation field of magnesium alloy, can solve the problems of small size of powder metallurgy products, cannot meet the needs of large components and structural diversification, and achieve the effect of large degree of work hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] a. Pre-deform the semi-continuous casting ingot (with a diameter of Φ97mm and a length of 5000mm) into a rod (with a size of Φ22mm.

[0016] b. The pre-deformed bar is strongly and rapidly compressed and deformed at room temperature. The radial compression speed of the hammer head is 3 times per second, the axial movement speed is 1500mm per minute, and the motor power is 15KW. The shrinkage rate is 21.44%;

[0017] c. After strong deformation, the bar is subjected to isothermal aging at 220°C, and the aging time is 20h;

[0018] After aging treatment, the mechanical performance test was carried out according to GB / T228-2002, the results are shown in Table 1, and the macroscopic photos of the products are shown in figure 1 .

Embodiment 2

[0020] a. Pre-deform the semi-continuous casting ingot (diameter Φ97mm, length 5000mm) into a bar (size Φ22mm).

[0021] b. The pre-deformed bar is strongly and rapidly compressed and deformed at room temperature. The radial compression speed of the hammer head is 3 times per second, the axial movement speed is 1500mm per minute, and the motor power is 15KW. The shrinkage rate is 36.73%;

[0022] c. After strong deformation, the bar is subjected to isothermal aging at 180°C, and the aging time is 100h;

[0023] After aging treatment, the mechanical performance test is carried out according to GB / T228-2002, the results are shown in Table 1, and the macroscopic photos of the product are shown in figure 1 .

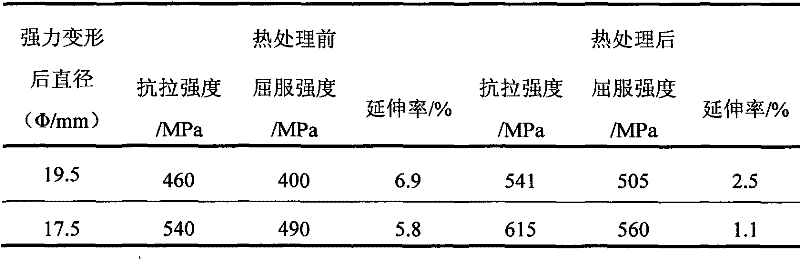

[0024] Table 1 Tensile mechanical properties of strongly deformed magnesium alloys at room temperature

[0025]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com