A hydraulic bulging forming method for a non-ferrous metal tee

A non-ferrous metal and tee technology, applied in the field of non-ferrous metal tee forming, can solve the problems that are difficult to meet the requirements of "finish, clean and economical", the forming accuracy of tee pipe fittings is not high, and the product is unevenly stressed, so as to eliminate Residual stress and work hardening problems, low labor intensity of workers, and the effect of overcoming internal dislocation proliferation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

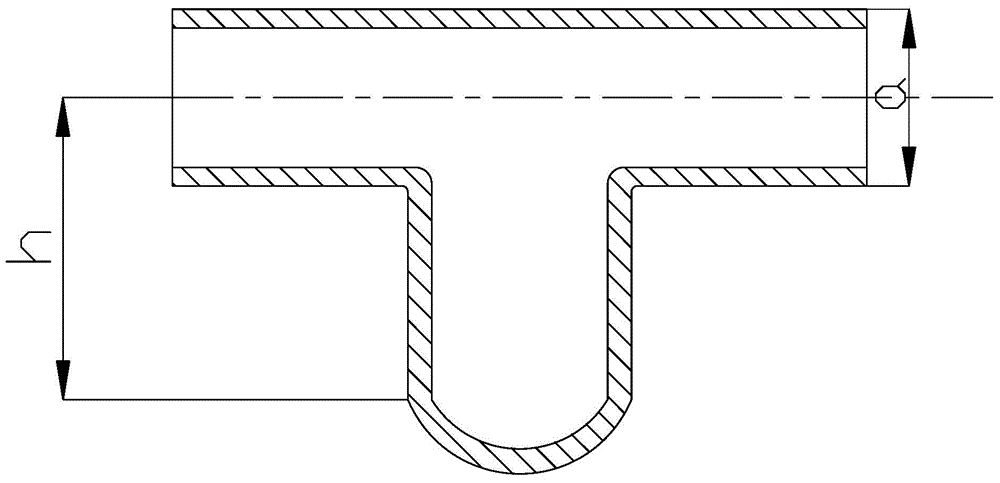

[0039] Manufacture of C-276 nickel-based alloy tee with Ф48.3×2.77mm and branch pipe height of 58.15mm:

[0040] Step 1. Carry out surface eddy current testing on the C-276 nickel-based alloy tube billet according to JB / T4730.6-2005, select a tube billet without defects such as cracks and inclusions, and conduct ultrasonic testing according to JB / T4730.3-2005, and select Tube blanks without internal defects such as delamination; according to the principle of constant metal volume, sawing and cutting straight tube blanks, deburring, cleaning and removing impurities and oil stains attached to the inner and outer surfaces of the tube blanks, and then smearing on the outer surface of the tube blanks Lubricant S-0 forged graphite emulsion;

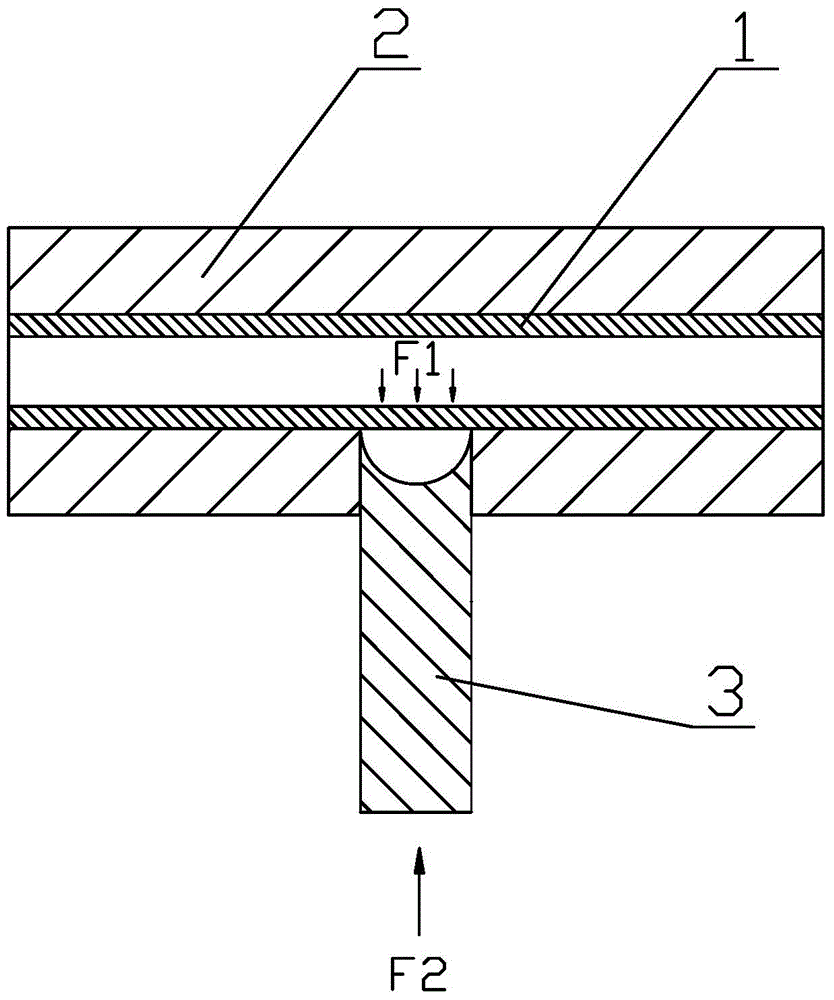

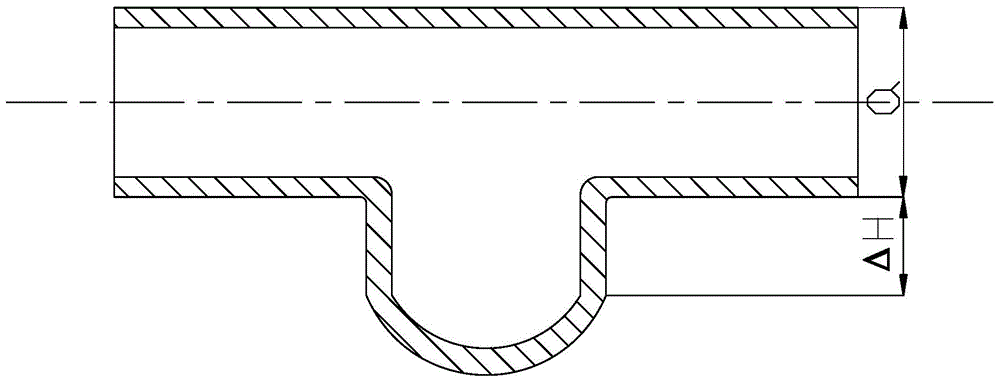

[0041] Step 2. Select a mold according to the size of the tee that needs to be formed, place the tube blank coated with lubricant in step 1 in the mold cavity, and set a layer of plastic film between the outer wall of the tube blank and the inn...

Embodiment 2

[0053] Manufacturing of R60702 pure zirconium tee with Ф60.3×3.91mm and branch pipe height of 64.15mm:

[0054] Step 1. Conduct surface eddy current testing on the R60702 pure zirconium tube billet according to JB / T4730.6-2005, select the tube billet without cracks, inclusions and other defects, and conduct ultrasonic testing according to JB / T4730.3-2005, select no delamination Tube blanks with internal defects; according to the principle of constant metal volume, sawing and cutting straight tube blanks, deburring, cleaning and removing impurities and oil stains attached to the inner and outer surfaces of the tube blanks, and then applying lubricant S to the outer surface of the tube blanks -0 forged graphite milk;

[0055] Step 2. Select a mold according to the size of the tee that needs to be formed, place the tube blank coated with lubricant in step 1 in the mold cavity, and set a layer of plastic film between the outer wall of the tube blank and the inner wall of the mold;...

Embodiment 3

[0067] Ф33.4×1.65mm, the manufacture of TA2 pure titanium tee with a branch pipe height of 38.7mm:

[0068] Step 1. Conduct surface eddy current testing on TA2 pure titanium tube blanks according to JB / T4730.6-2005, select tube blanks without defects such as cracks and inclusions, and conduct ultrasonic testing according to JB / T4730.3-2005, and select no delamination Tube blanks with internal defects; according to the principle of metal volume invariance, sawing and cutting straight tube blanks, deburring, cleaning and removing impurities and oil stains attached to the inner and outer surfaces of the tube blanks, and then applying lubricant two to the outer surface of the tube blanks Molybdenum sulfide;

[0069] Step 2. Select a mold according to the size of the tee that needs to be formed, place the tube blank coated with lubricant in step 1 in the mold cavity, and set a layer of plastic film between the outer wall of the tube blank and the inner wall of the mold;

[0070] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com