Crank-rocker quick mechanism

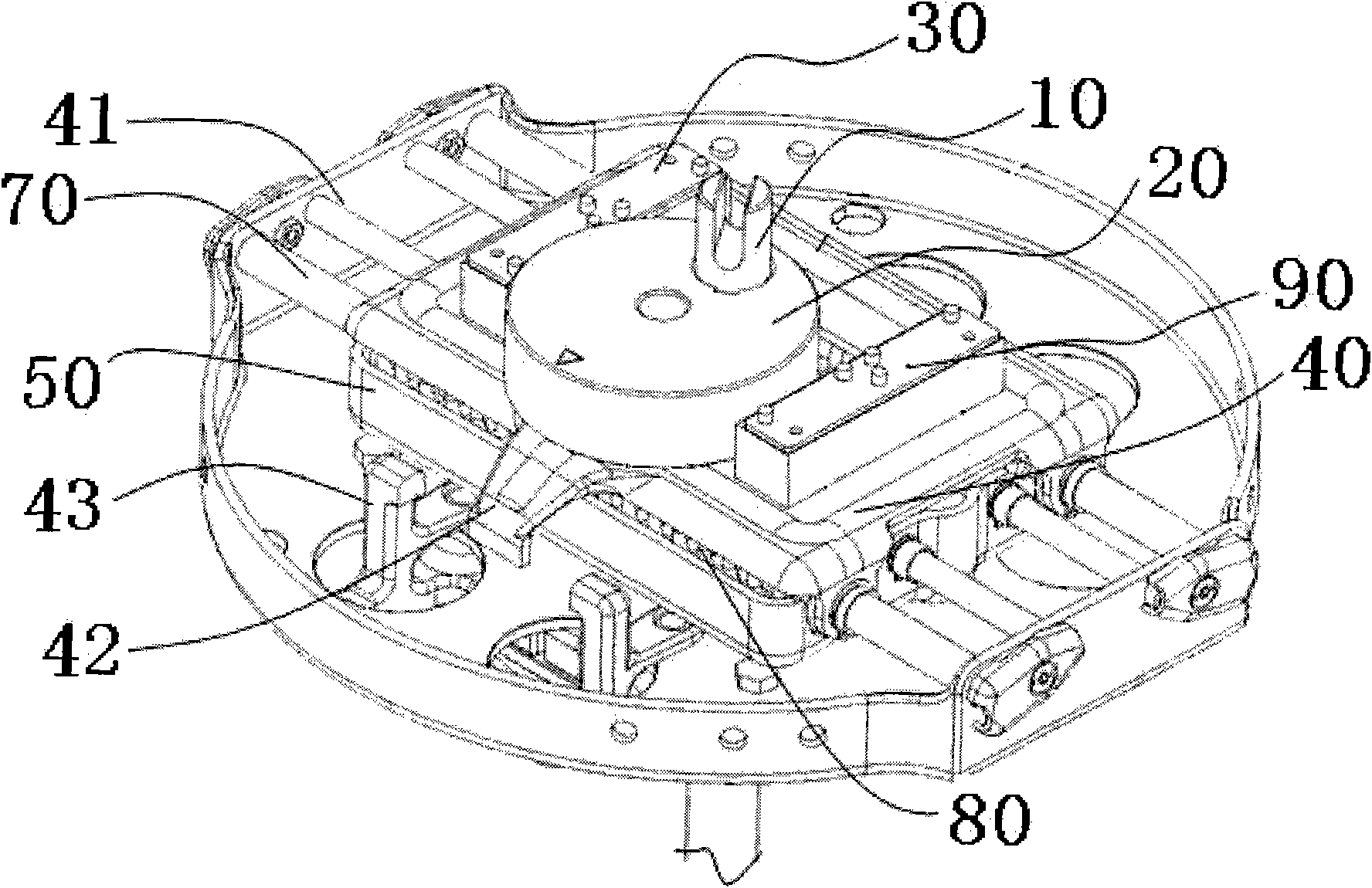

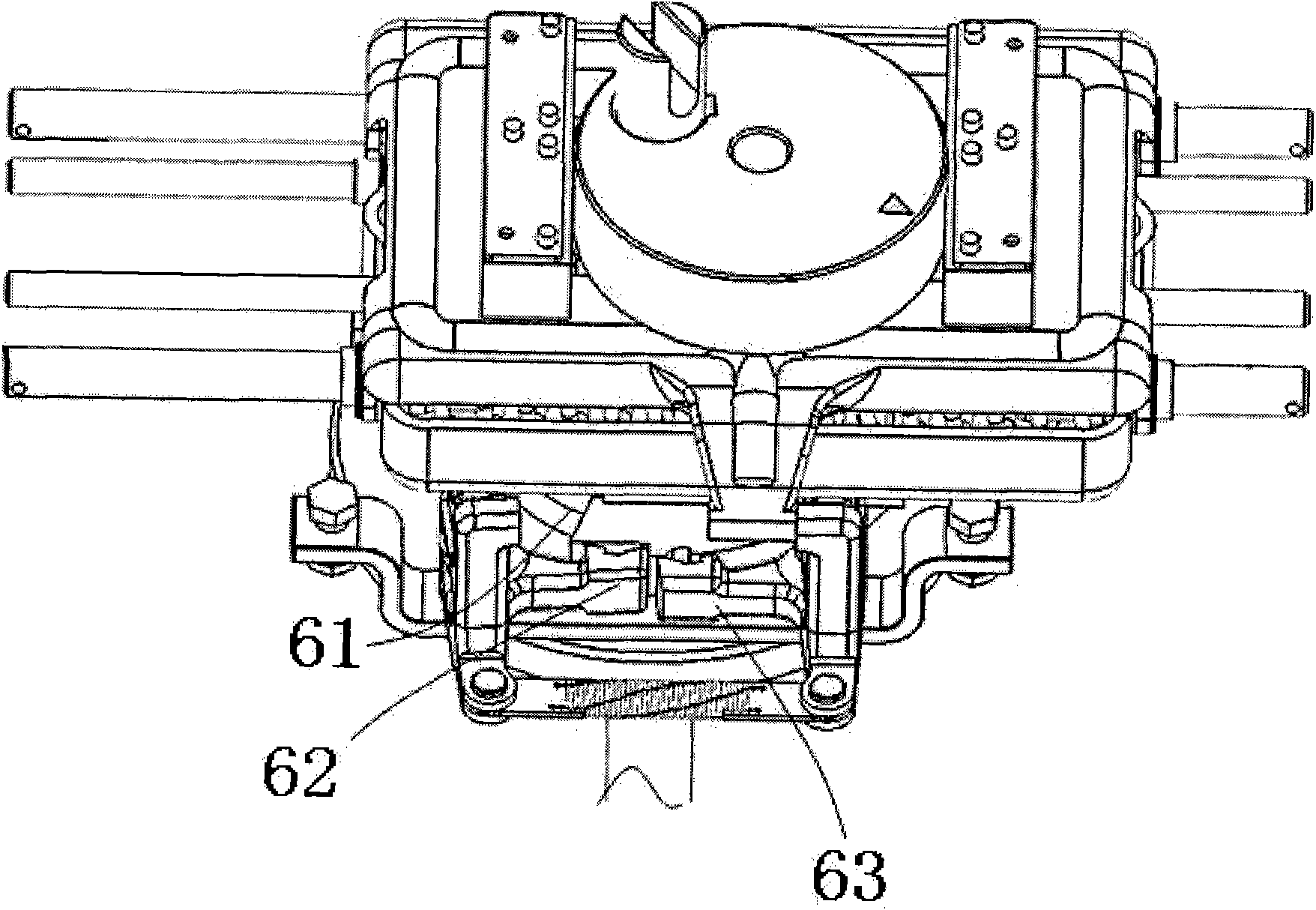

A crank-rocker mechanism and crank-rocker technology, which is applied in the direction of prior contact arrangement, power device inside the switch, etc., can solve the problems of increased manufacturing cost, many friction components, mechanical failure, etc., and achieve low mechanical failure rate and manufacturing cost , small resistance, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

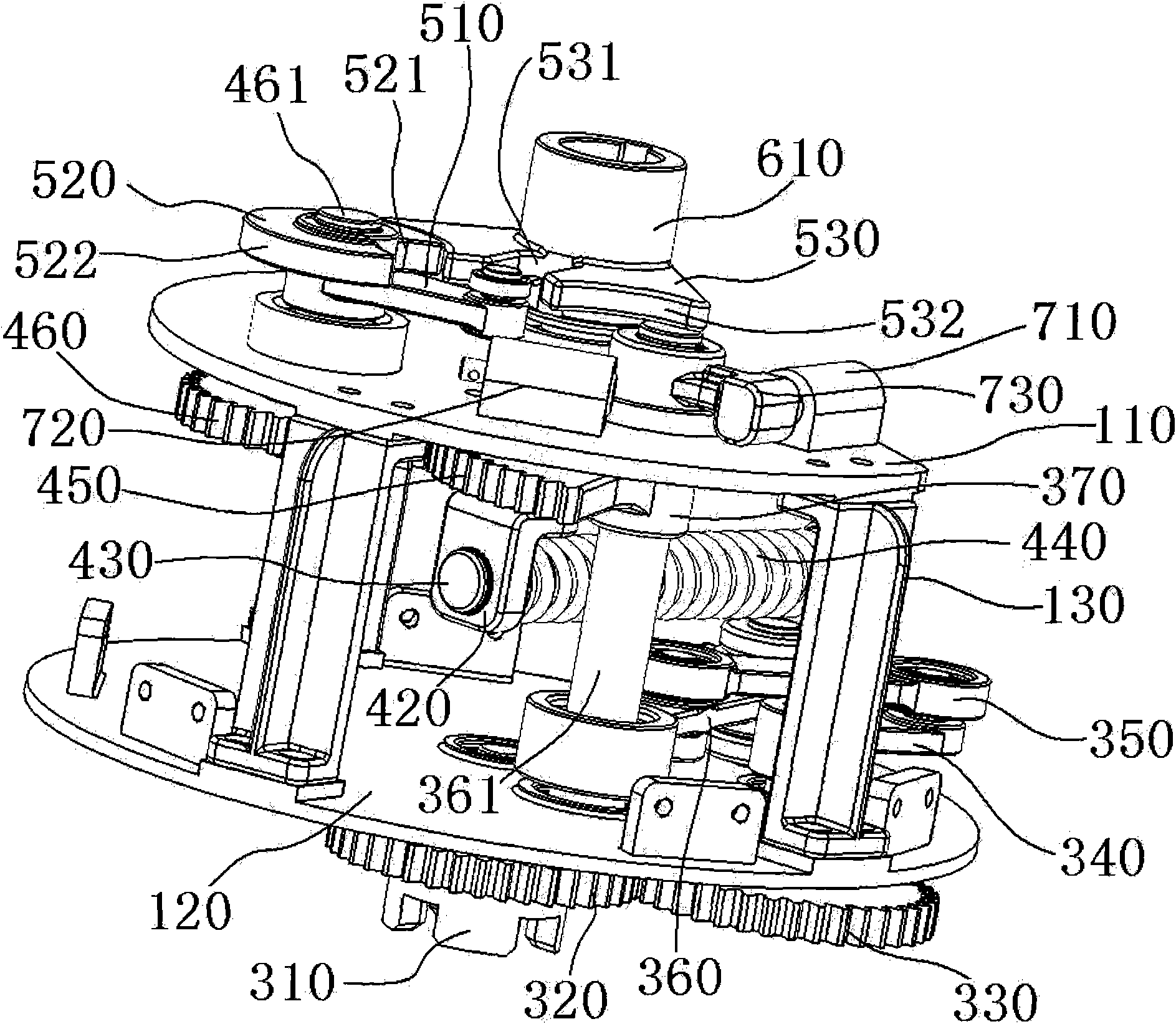

[0069] see image 3 , the crank-rocker fast mechanism shown includes upper and lower mounting plates 110, 120 for installation. The shapes of the upper and lower mounting plates 110, 120 can be designed according to the requirements of the on-load tap changer. The upper and lower mounting plates 110, 120 are connected by three brackets 130, leaving an installation space for the upper and lower mounting plates 110, 120 to facilitate the installation of various parts.

[0070] The tooth coupling 310 and the driving gear 320 are coaxially installed on the lower mounting plate 120 and are located below the lower mounting plate 120 . The driven gear 330 and the first end of the crank 340 are also coaxially installed on the lower mounting plate 120 , wherein the driven gear 330 is located below the lower mounting plate 120 , and the crank 340 is located above the lower mounting plate 120 .

[0071] The jaw coupling 310 is connected with the output shaft (not shown in the figure) of...

Embodiment 2

[0083] see Figure 12 , the crank-rocker fast mechanism shown includes upper and lower mounting plates 110, 120 for installation. The shapes of the upper and lower mounting plates 110, 120 can be designed according to the requirements of the on-load tap changer. The upper and lower mounting plates 110, 120 are connected by three brackets 130, leaving an installation space for the upper and lower mounting plates 110, 120 to facilitate the installation of various parts.

[0084] The jaw coupling 310 and the driving gear 320 are coaxially installed on the lower mounting plate 120 and are located below the lower mounting plate 120, and the first end of the driven gear 330 and the crank 340 are also coaxially installed on the lower mounting plate 120, wherein the driven gear The gear 330 is located below the lower mounting plate 120 , and the crank 340 is located above the lower mounting plate 120 .

[0085]The jaw coupling 310 is connected with the output shaft (not shown in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com