Cutting tube

A technology for cutting tubes and slits, applied in the fields of application, tobacco, and paper cigarette manufacturing, which can solve problems such as poor cutting quality, production interruption, and limited machine availability, and achieve the effect of preventing deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

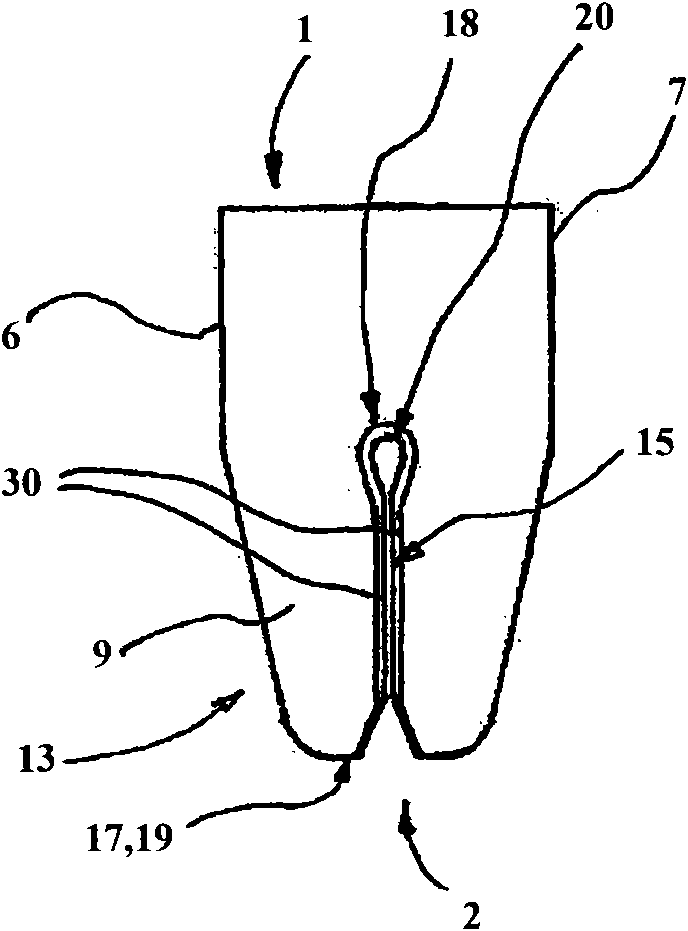

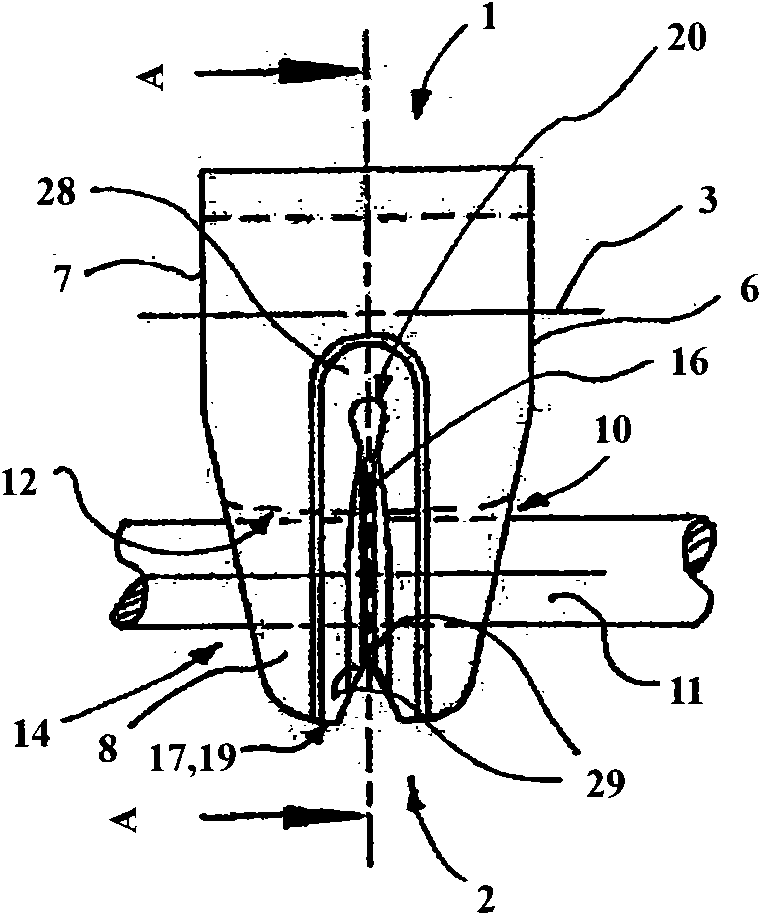

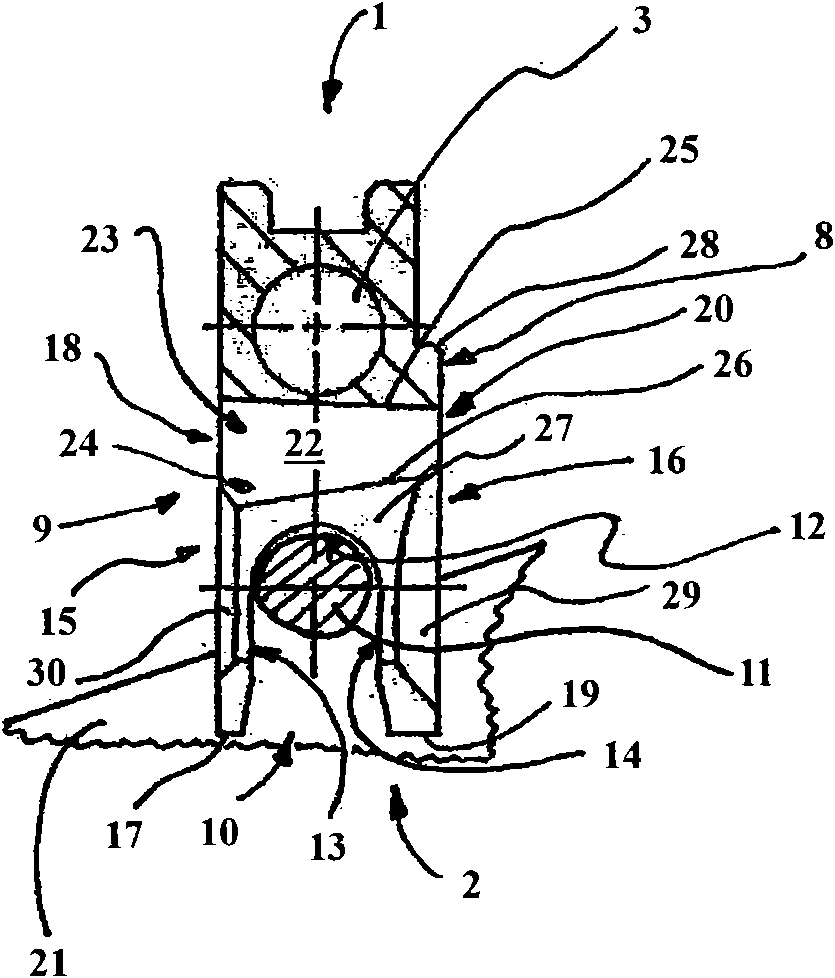

[0054] exist Figure 1 to Figure 4 The cutting tube shown in is substantially constructed almost like a double fork (Doppel-Gabel) and comprises two guiding forks arranged transversely relative to each other, one of which is located in the strip 11 guides the strip 11 during the cutting of the strip and the other guides the knife 21 during the cutting of the strip.

[0055] The cut tube comprises a fastening end 1 and a free end 2 opposite the fastening end 1, as shown in particular by image 3 as visible.

[0056] The fastening end 1 is provided with a rectangular fastening groove in cross-section that is open upwards and outwards for receiving a likewise not shown form of a support arm (not shown). The fastening end 1 is provided with a cylindrical bore 3 extending parallel to the aforementioned groove for receiving a not shown clamping bolt, which has two threaded holes for receiving a fastening screw. The bottom of the aforementioned fastening groove has two pass-through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com