Unpowered dust removal device

A technology of dust removal device and power, which is applied in the direction of combination device, separation of dispersed particles, chemical instruments and methods, etc., and can solve problems such as inability to completely remove dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

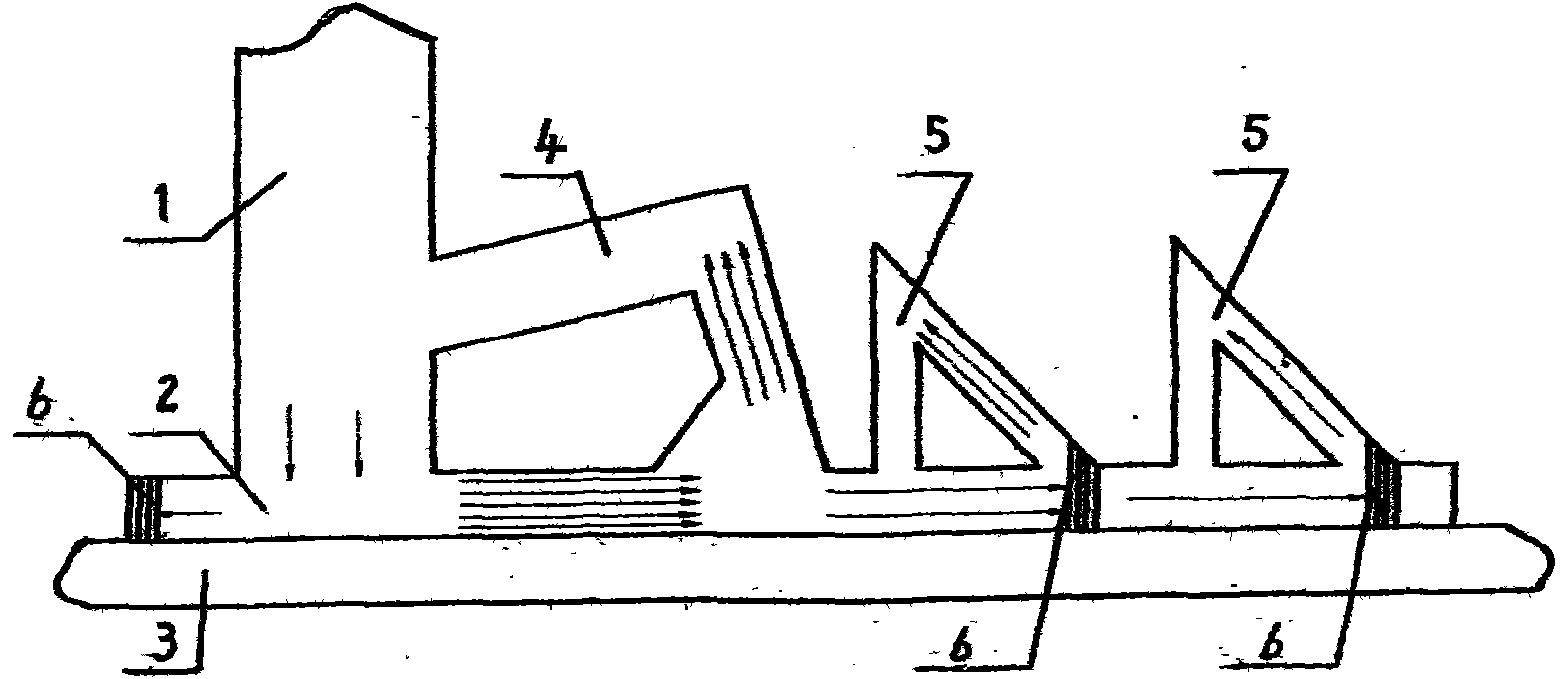

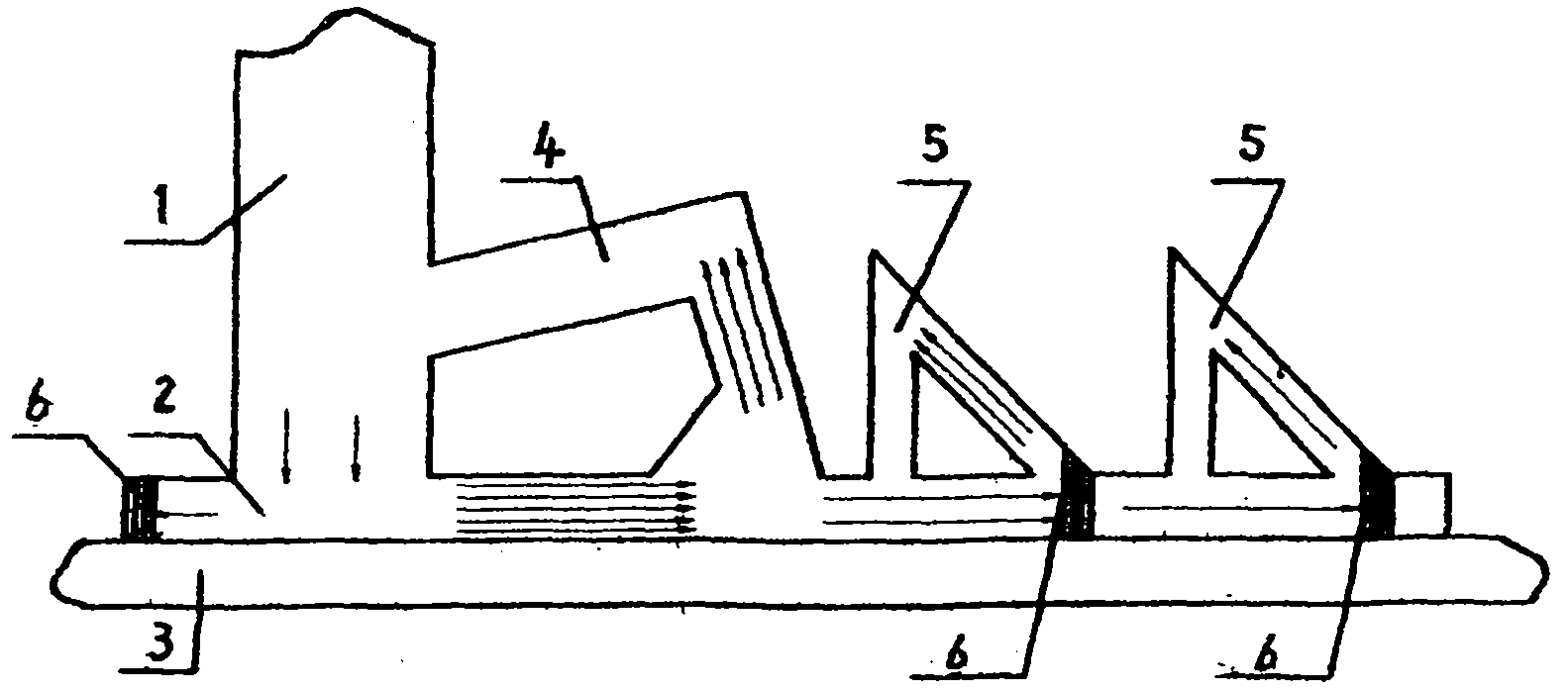

[0013] The non-powered dust removal device of the present invention utilizes the physical siphon principle and energy conservation principle applied in the above-mentioned prior art, adopts a relatively sealed structure, and sets an environment where the dust energy is depleted, so that the dust falls back on the transmission belt regularly to complete effective dust removal. In the non-powered dedusting device of the present invention, a dust return-shaped revolving channel is set, and no dust-proof curtain is installed at the material outlet of the revolving-shaped dust revolving channel, and the method of step-down dust removal and synchronous multi-channel dust removal is adopted, which not only solves the problem of coal dust The deflagration problem makes the dust removal effect more ideal, which can fully meet the requirements of GB16248-1996 "Hygienic Standards for Respirable Dust in Air in Workplaces".

[0014] A detailed description will be made below in conjunction w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com