Patents

Literature

45results about How to "Reduce disposal time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

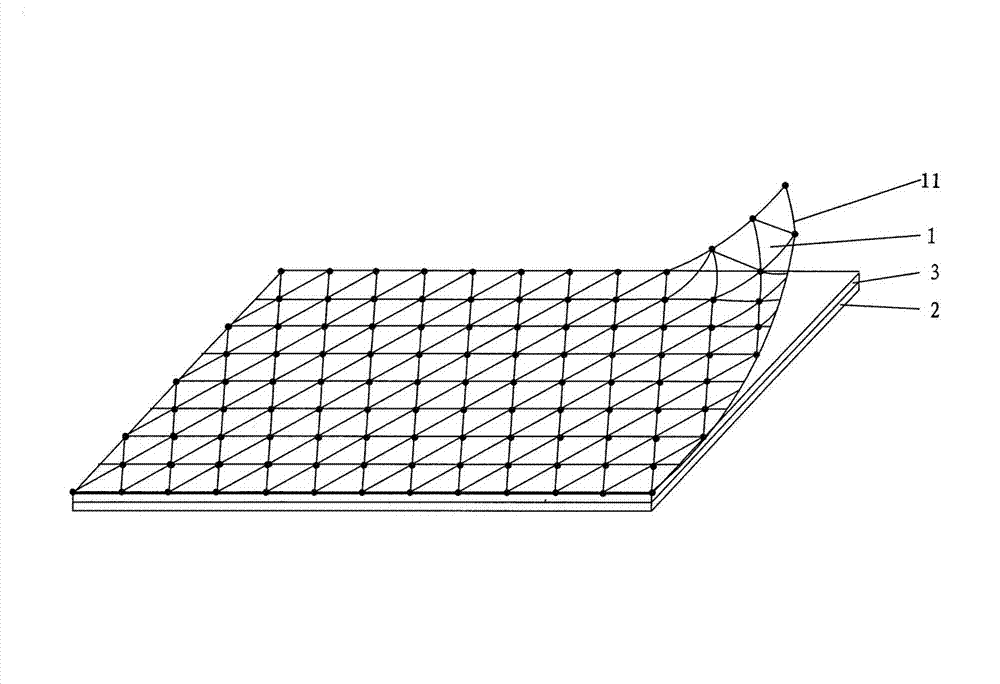

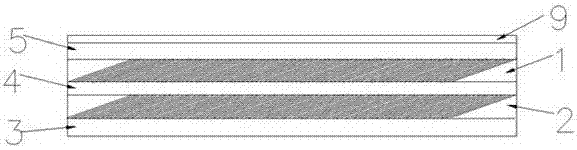

Manufacturing method of composite medical non-woven fabric absorbent pads

The invention relates to a manufacturing method of composite medical non-woven fabric absorbent pads and belongs to the field of preparation of medical dressing. The manufacturing method includes steps of feeding medical non-toxic polyethylene particles into a screw extruder to fuse and extrude, forming a film through curtain coating, rolling to form anti-adhesive holes, cooling and winding to obtain a medical non-toxic polyethylene film used as an anti-adhesive layer; subjecting blended fibers blended by viscose fibers and high-absorbent fibers to opening by an opener, carding by a carding machine, lapping by a lapping machine and needling by a needle machine, and obtaining non-woven fabric used as a liquid absorbent layer; feeding polyurethane particles into the screw extruder to fuse and extrude, and forming a film by curtain coating, cooling and winding to obtain a polyurethane film used as a waterproof breathable layer; subjecting the anti-adhesive layer and one surface of the liquid absorbent layer to thermal compositing, and subjecting the waterproof breathable layer and the other surface of the liquid absorbent layer to thermal compositing to obtain a composite medical non-woven fabric absorbent pad. The manufacturing method of the composite medical non-woven fabric absorbent pads has the advantages that liquid absorbent quantity is high, leakage to the outside is prevented, contact area of the skin can be remarkably decreased, handling time of medical staff can be shortened, and technical steps are few.

Owner:SUZHOU EMY MEDICAL SUPPLIES

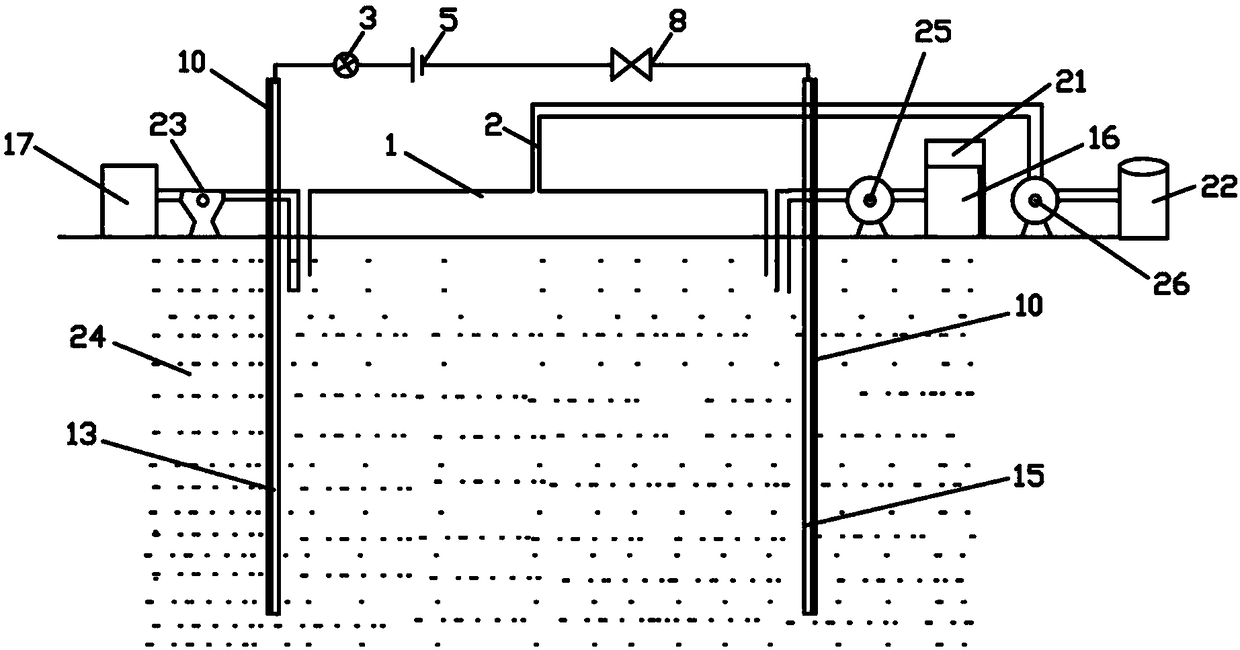

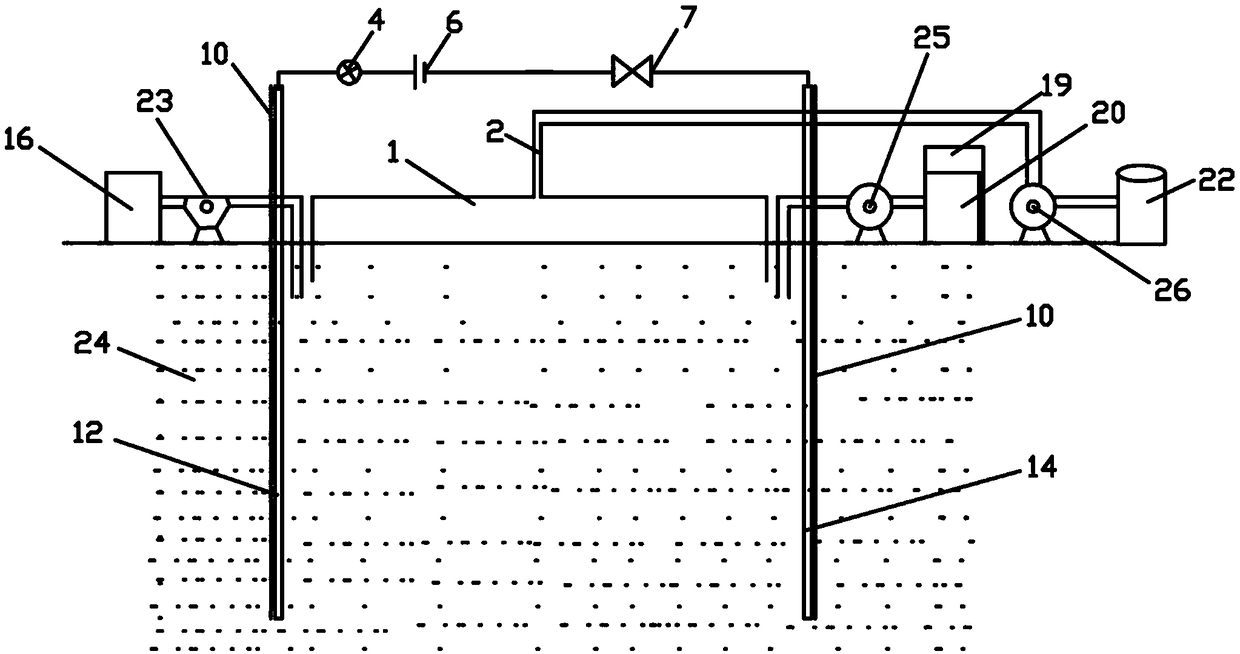

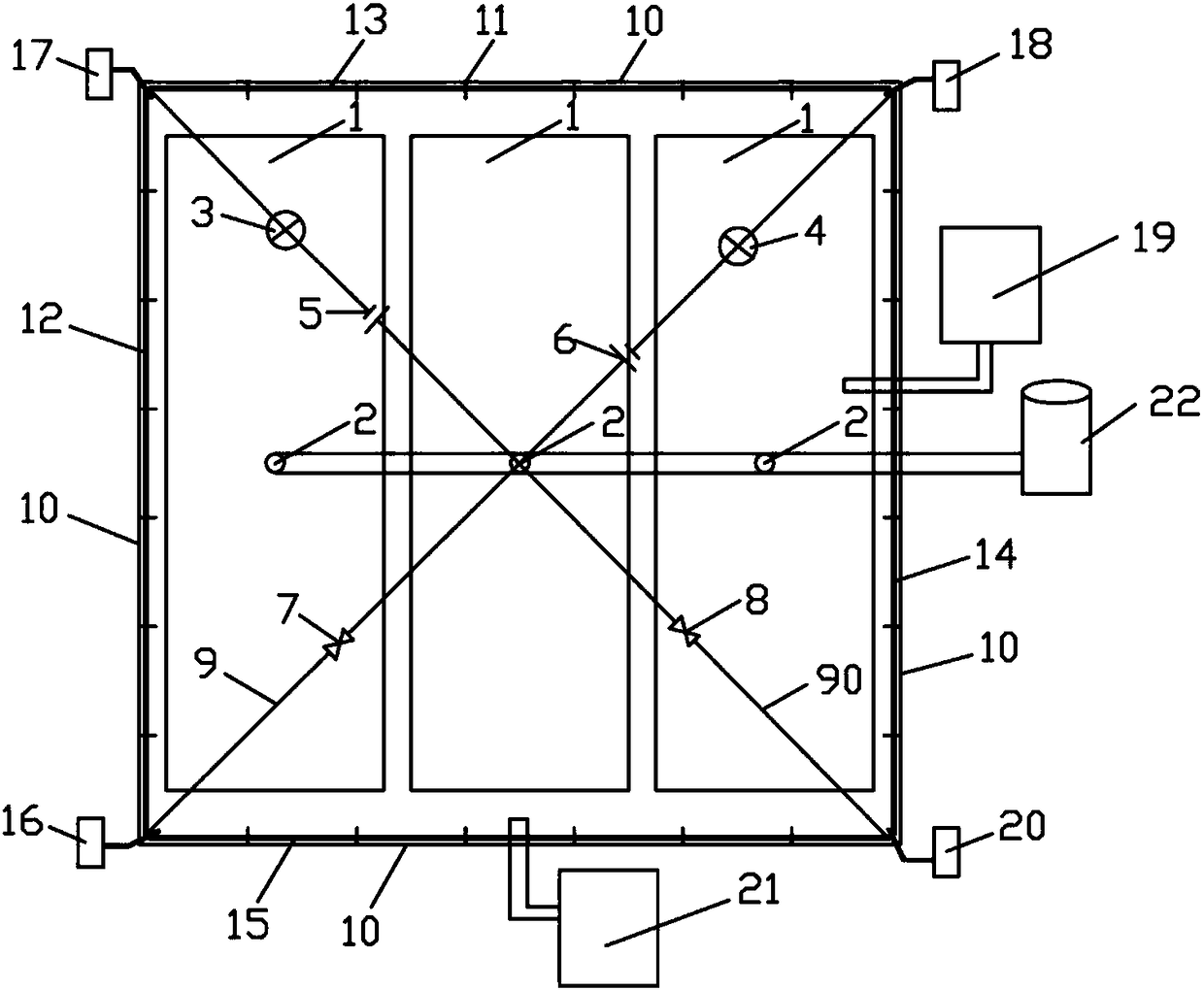

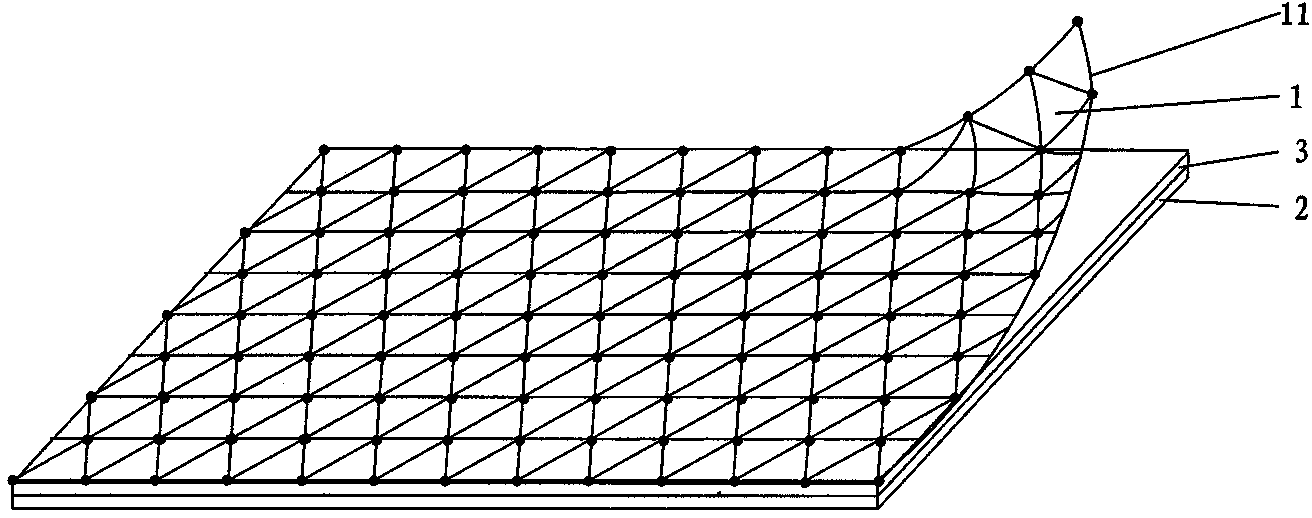

In-situ restoration system and method for river-lake bottom mud polluted by heavy metals

PendingCN108341569AImprove corrosion resistanceImprove repair effectSludge treatment by de-watering/drying/thickeningWater contaminantsElectrokinetic remediationSewage discharge

The invention relates to the technical field of in-situ restoration and dewatering for pollution of river-lake bottom mud and particularly relates to an in-situ restoration system and method for the river-lake bottom mud polluted by heavy metals. The system comprises a steel-plate mold frame with a square-shaped structure, wherein the lower part of the steel-plate mold frame is inserted and driveninto the river-lake bottom mud; a volatile organic pollutant gas collecting bag is arranged at the upper part of the steel-plate mold frame and is connected to a volatile organic pollutant gas disposal system by a gas suctioning pipeline; the four corners of the steel-plate mold frame are respectively provided with a non-volatile organic pollutant disposal device I, a heavy-metal and volatile organic pollutant disposal device, a non-volatile organic pollutant disposal device II and a non-volatile organic pollutant disposal device III; the steel-plate mold frame is also provided with an electric restoration system and a sewage discharging system. The in-situ restoration system and method have the beneficial effects that electric restoration and dewatering technologies are applied in disposal of the river-lake bottom mud simultaneously, the economic-practical effects and the environment-friendly effect are achieved, the effect is better, the method is simple in operation, and no secondary pollution is generated.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

Medical antibacterial compound dressing

The invention discloses a medical antibacterial composite dressing, comprising a first antibacterial layer, a second antibacterial layer and a liquid-absorbing layer, the first antibacterial layer and the second antibacterial layer are bonded by an adhesive layer, and the surface of the first antibacterial layer A non-woven fabric layer is provided, and the liquid-absorbing layer is arranged on the surface of the second antibacterial layer. The present invention has the advantages of simple structure, antibacterial and antibacterial, breathable, and good flexibility, and has high liquid-absorbing efficiency, effectively shortening the disposal time of medical personnel. time.

Owner:MAANSHAN NIUZE TECH SERVICE

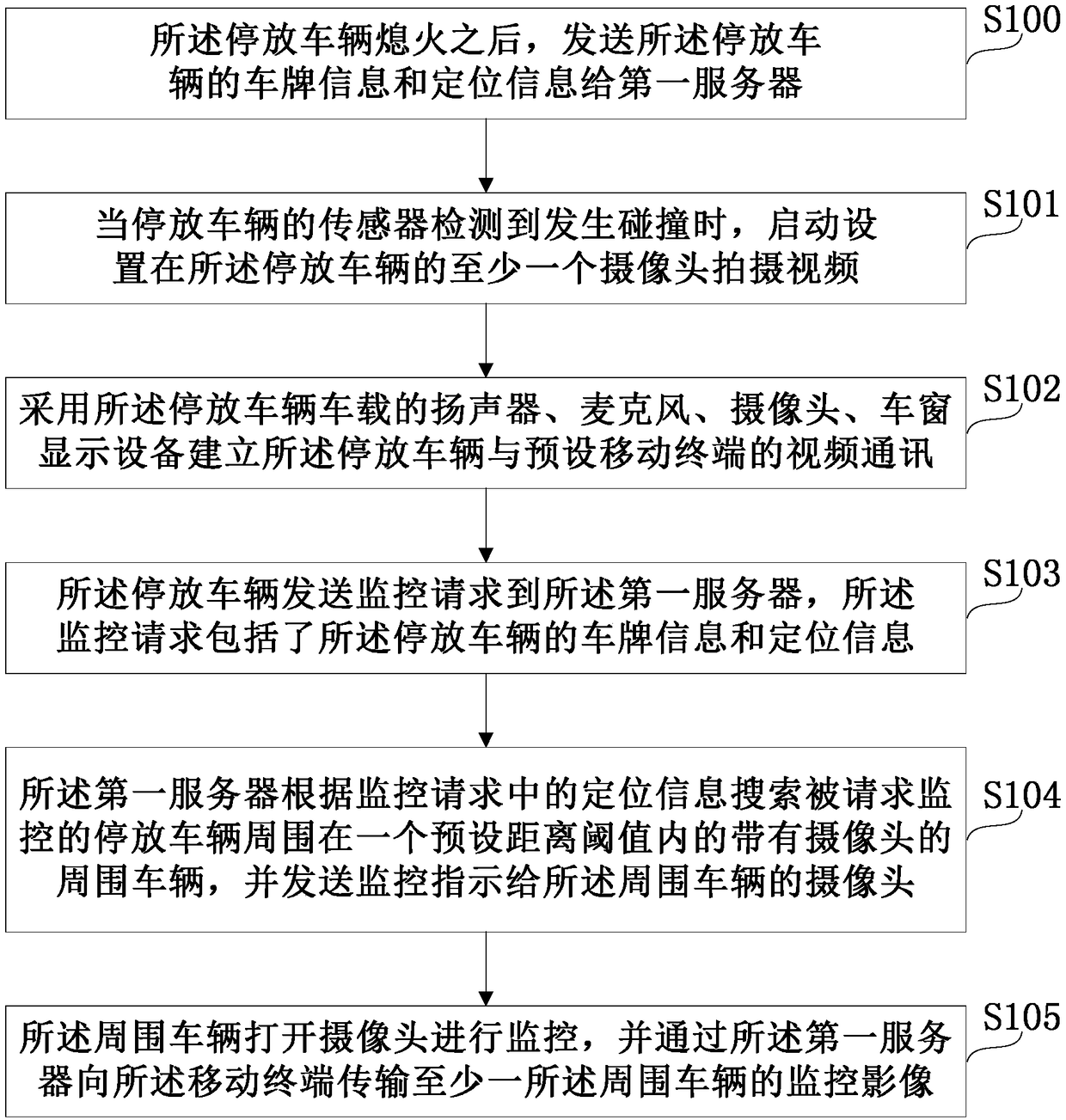

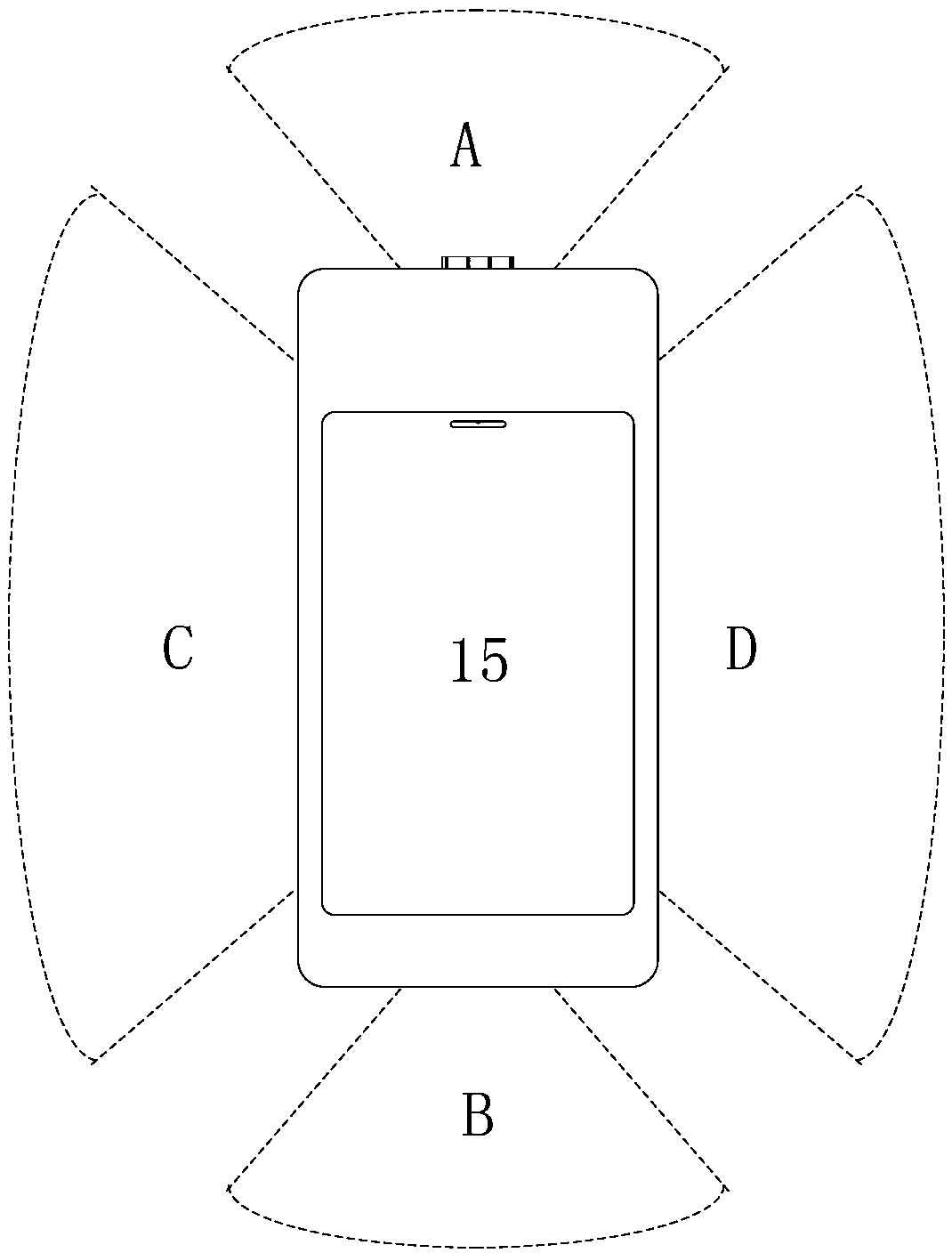

Method, system, device and storage medium for video communication after collision of parked vehicles

InactiveCN109218682AFacilitate direct communicationReduce disposal timeClosed circuit television systemsTwo-way working systemsDisplay deviceDirect communication

The invention provides a method, a system, a device and a storage medium for video communication after the collision of parked vehicles. The method comprises the following steps: when a sensor of a parked vehicle detects a collision, at least one camera arranged on the parked vehicle is started to photograph video; when the sensor of the parked vehicle detects a collision, at least one camera arranged on the parked vehicle is started to photograph video. The video communication between the parked vehicle and the preset mobile terminal is established by using the vehicle-mounted loudspeaker, microphone, camera and window display device. The invention can establish the video communication between the accident party and the vehicle owner on the spot at the first time after the parked vehicleis collided, thereby facilitating the direct communication between the off-site vehicle owner and the accident party, shortening the handling time of the accident, reducing the handling difficulty ofthe traffic dispute, and improving the humanized experience.

Owner:AIWAYS AUTOMOBILE CO LTD

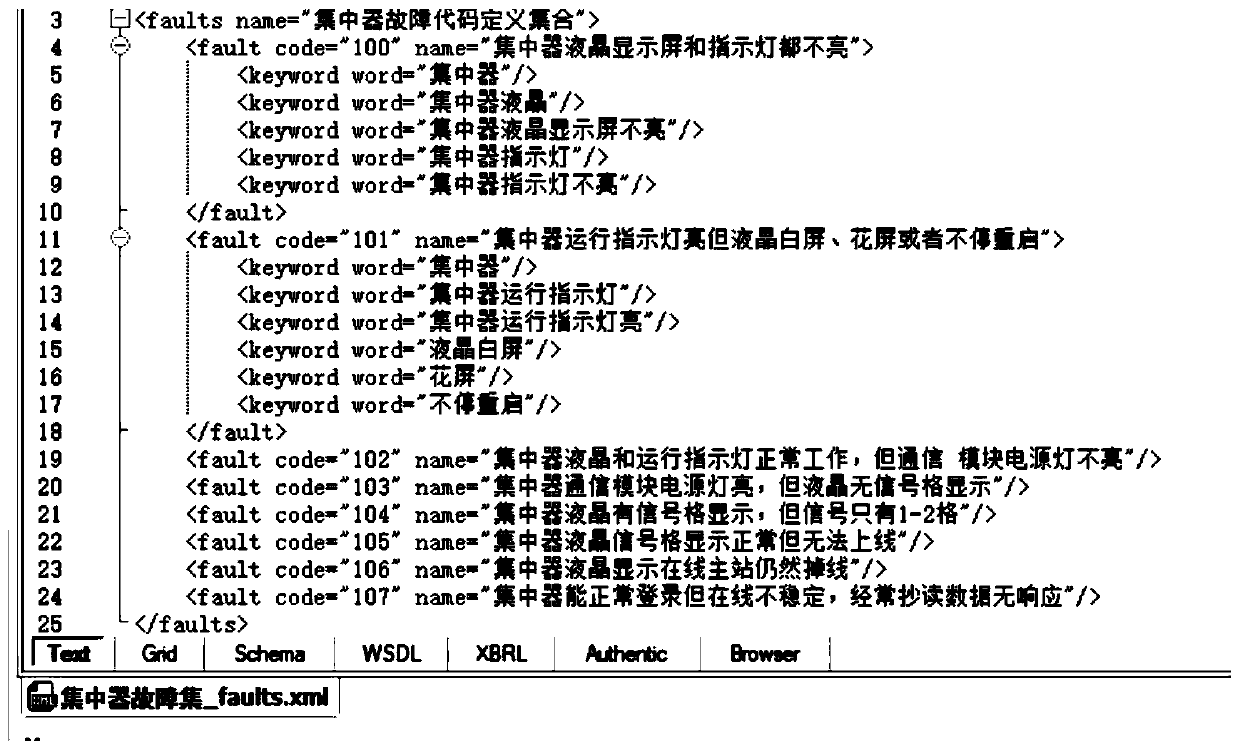

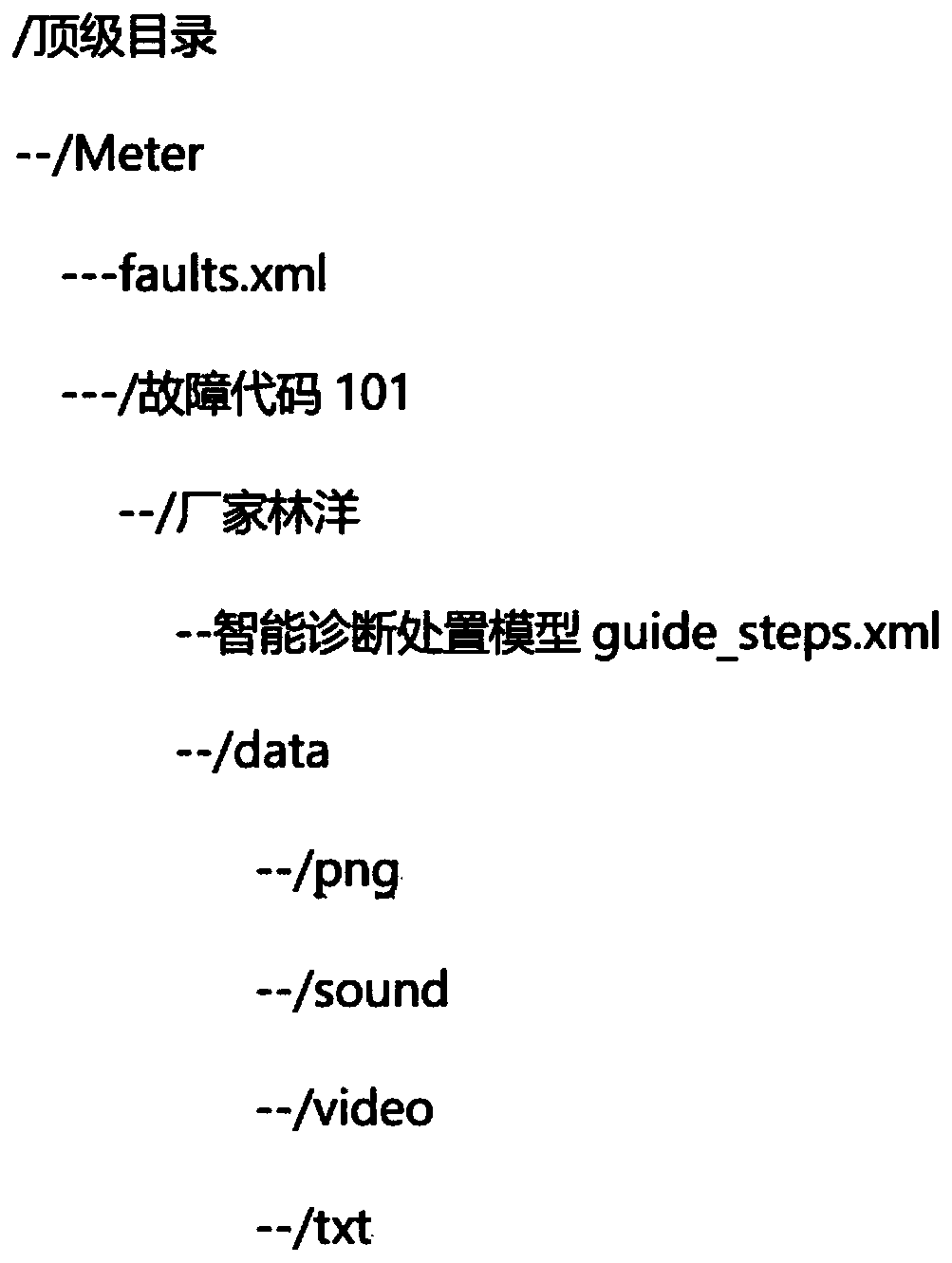

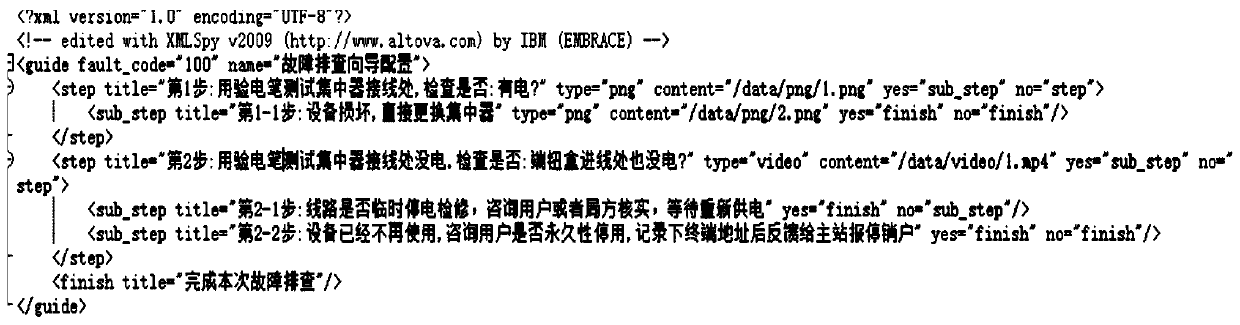

Knowledge database construction and management method for operation and maintenance of electric power metering equipment

ActiveCN110597791AEasy to set upImprove securityDatabase updatingData processing applicationsHuman powerTime cost

The invention discloses a knowledge database construction and management method for operation and maintenance of electric power metering equipment. The method comprises the following steps: defining afault operation and maintenance knowledge code set model in an xml format; setting a fault code definition set model file faults.xml of each metering equipment to adopt the xml format; a knowledge base operation and maintenance administrator adding, deleting, modifying and auditing operation and maintenance knowledge corresponding to each fault code of each device through a background web page; and constructing an xml format and a configured intelligent diagnosis and treatment model. The constructed database can achieve network access training at any time, update knowledge of operation and maintenance can be updated at any time and known in time, effective propaganda can be obtained in time, on-site operation and maintenance can be effectively supported, and labor and time cost is reduced.

Owner:GUIZHOU POWER GRID CO LTD

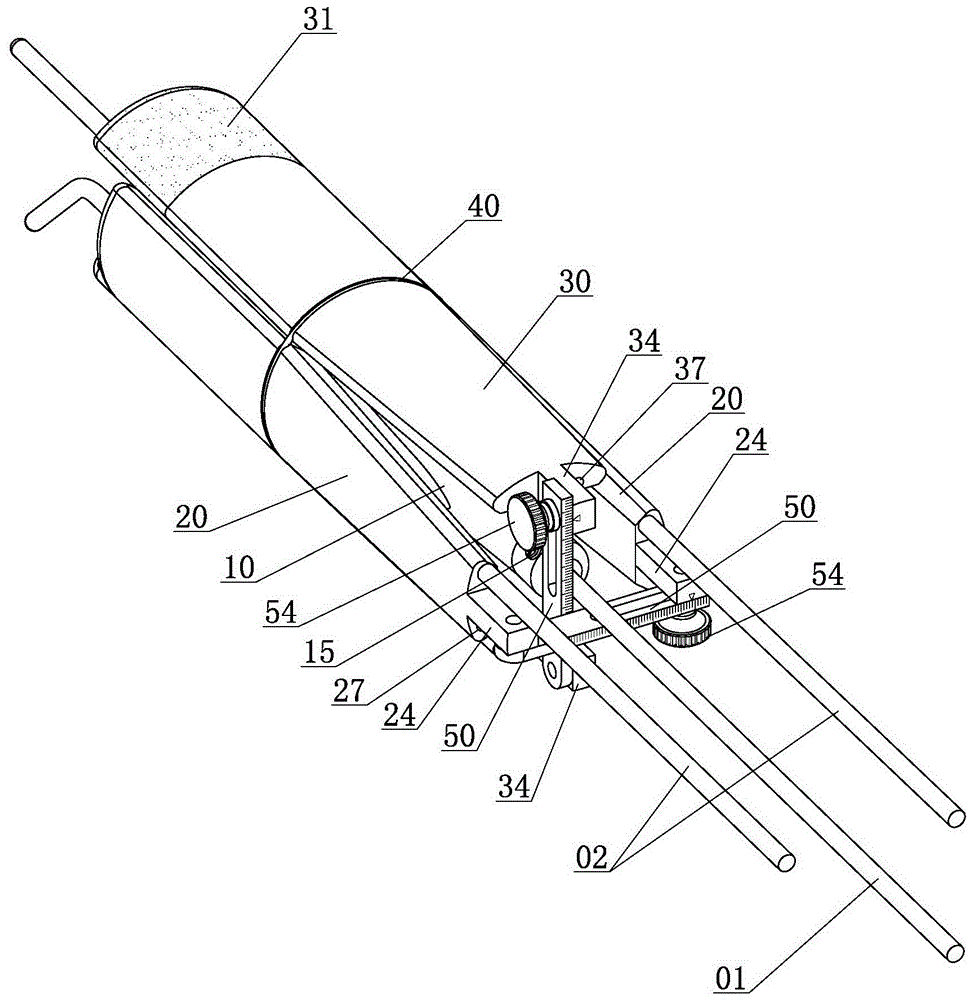

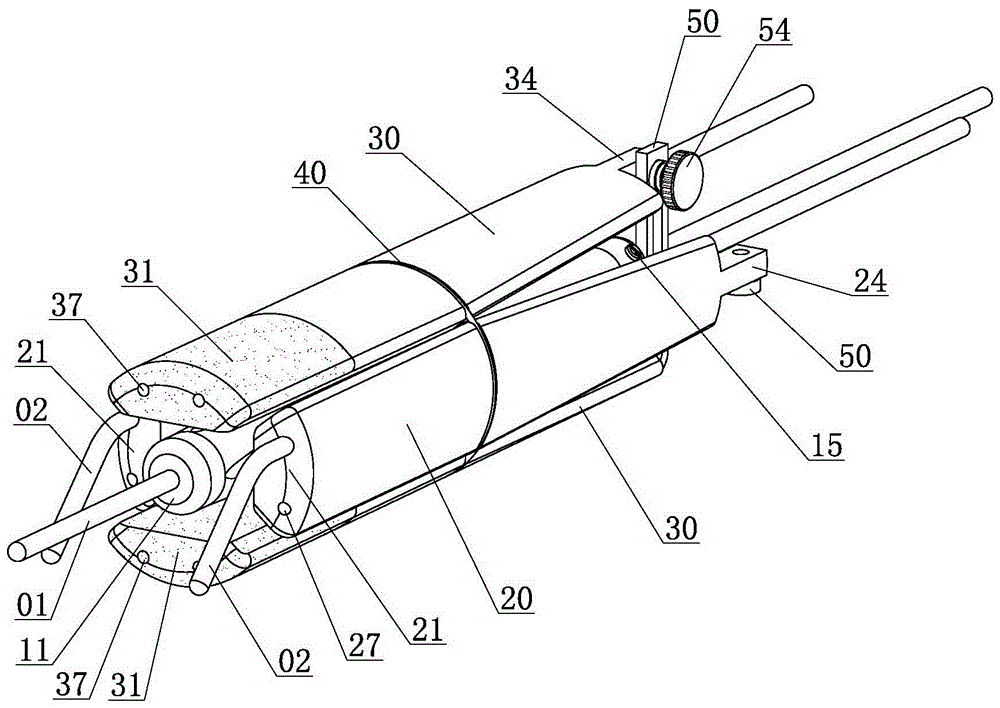

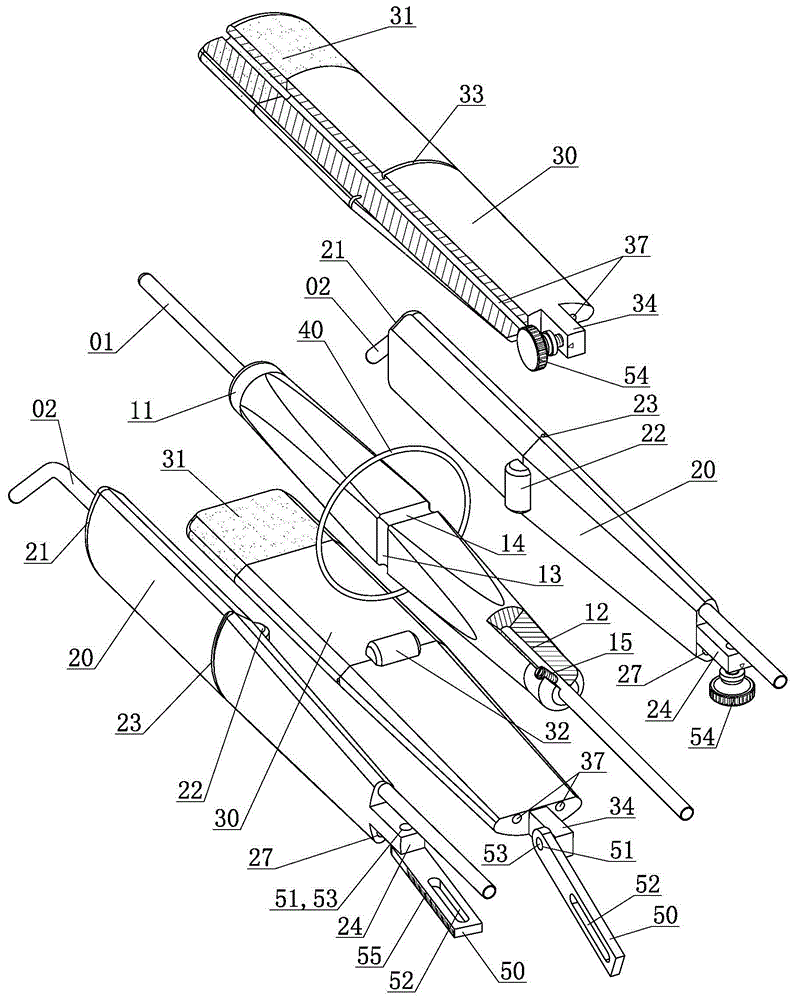

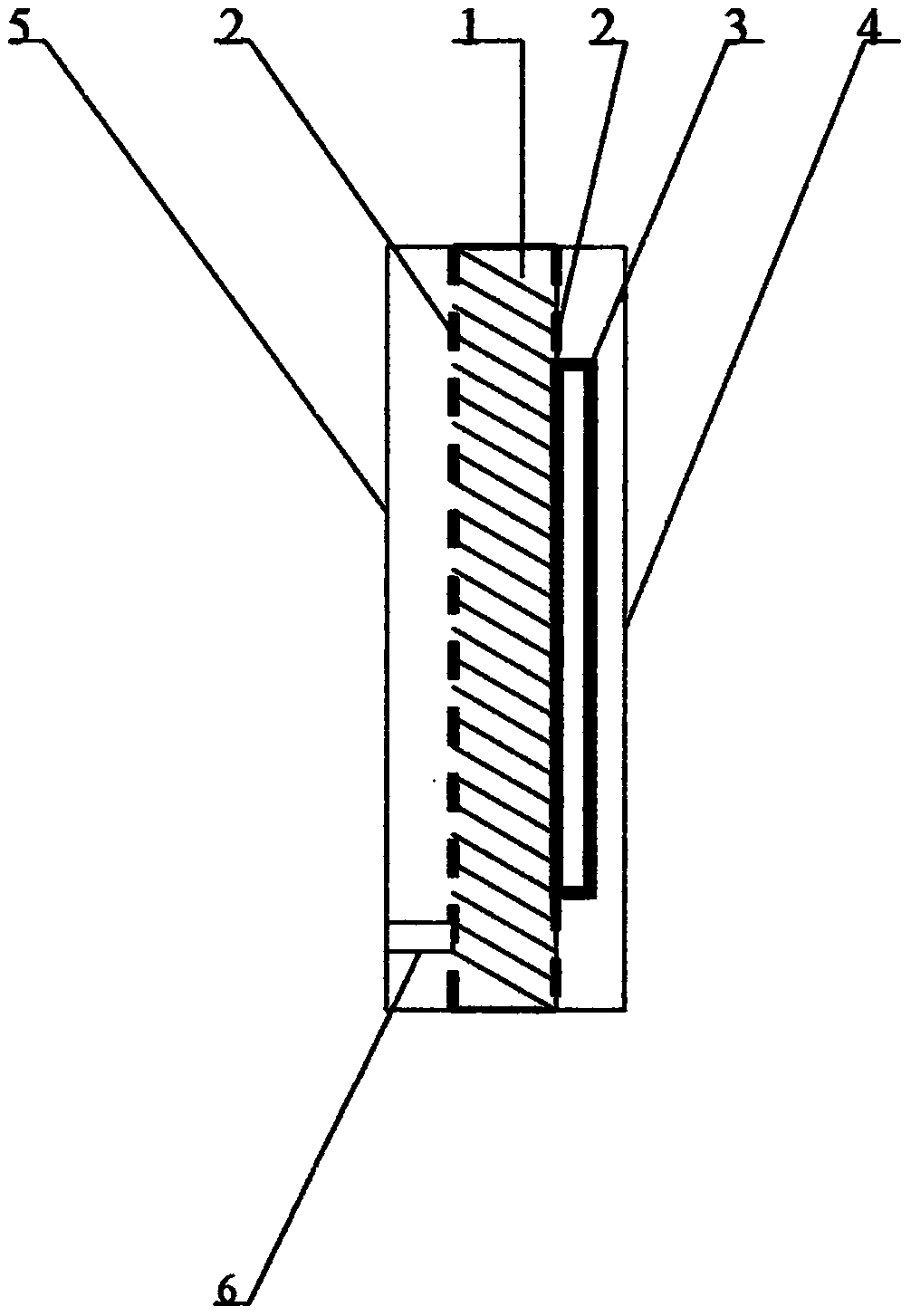

Filling-free source applicator for gynecological intracavity radiotherapy

ActiveCN105854187AAvoid stuffingRelieve painX-ray/gamma-ray/particle-irradiation therapyDistractionCatheter

The invention relates to a filling-free source applicator for gynecological intracavity radiotherapy. The filling-free source applicator comprises a uterine cavity catheter and two vault catheters. The uterine cavity catheter is mounted in a catheter seat, two vault guide blocks are respectively arranged on the left side and the right side of the catheter seat, and two vagina support blocks are respectively arranged on the front side and the rear side of the catheter seat; the two vault catheters are respectively mounted on the vault guide blocks on the left side and the right side of the catheter seat, two ends of each vault guide block can carry out lever rotation along the directions perpendicular to the axis of the uterine cavity catheter, and two ends of each vagina support block can carry out lever rotation along the directions perpendicular to the axis of the uterine cavity catheter. The filling-free source applicator has the advantages that the filling-free source applicator is provided with the vault guide blocks and the vagina support blocks which can be distracted, the vault catheters can be repositioned and fixedly positioned by the aid of the vault guide blocks, and the distances from the filling-free source applicator to the urinary bladders and the rectums of patients can be extended by the vagina support blocks by means of distraction; gauze filling can be omitted, accordingly, the filling-free source applicator is convenient to operate, stable and reliable effects can be realized, the disposal time can be obviously shortened, and suffering can be relieved for the patients.

Owner:PEKING UNION MEDICAL COLLEGE HOSPITAL CHINESE ACAD OF MEDICAL SCI

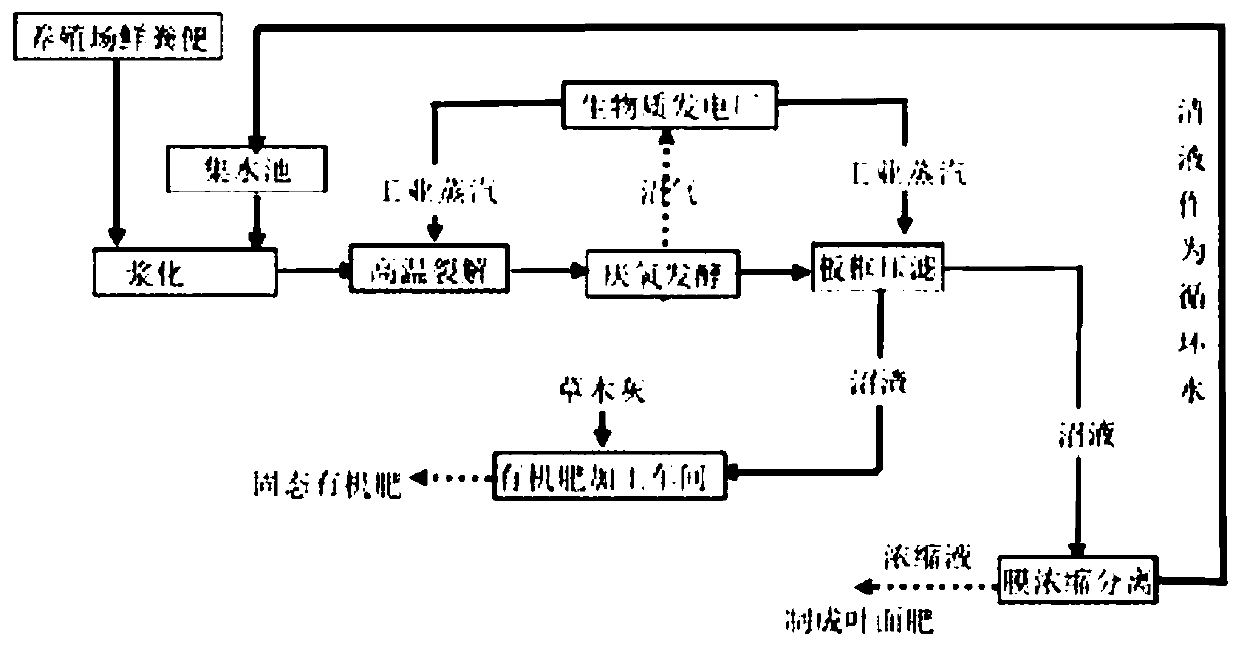

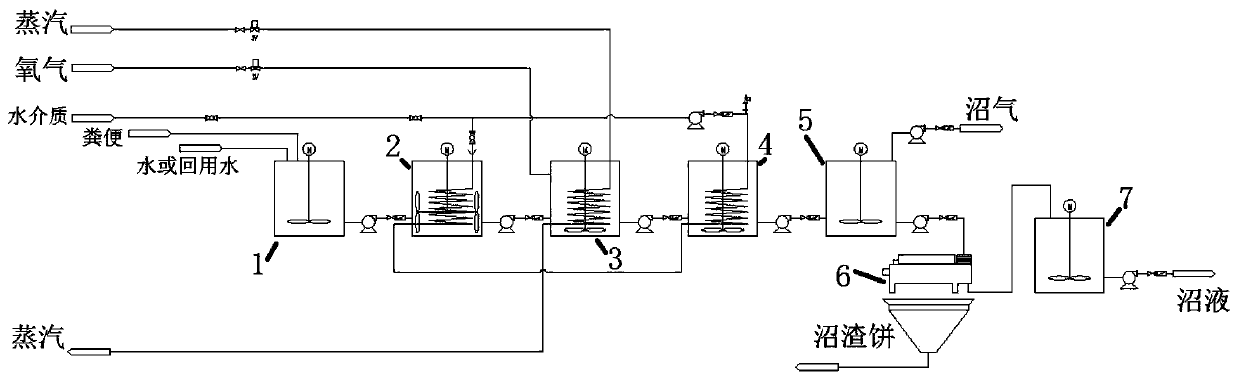

Livestock and poultry excrement disposal system and method taking energy and fertilizer into consideration

InactiveCN110420967AEasy to separateReduce COD concentrationWaste processingSolid waste disposalFecesSlurry

The invention discloses a livestock and poultry excrement disposal method taking energy and fertilizer into consideration. The method comprises the following steps of preparing excrement slurry, specifically, excrement and water are mixed in proportion to prepare the excrement slurry with the input concentration of 10%; carrying out fermentation pretreatment of the excrement slurry, specifically,a critical water oxidation reaction is carried out on the excrement slurry, bacteria is killed to break cell gaps to prepare for deep dehydration, and the reacted slurry is cooled; carrying out anaerobic fermentation, specifically, a medium-temperature anaerobic fermentation reaction is carried out on the cooled slurry to generate biogas; and dehydrating and drying, specifically, after fermentation, the slurry is dehydrated and dried to separate biogas residues from biogas slurry.

Owner:浙江中能环境科技有限公司

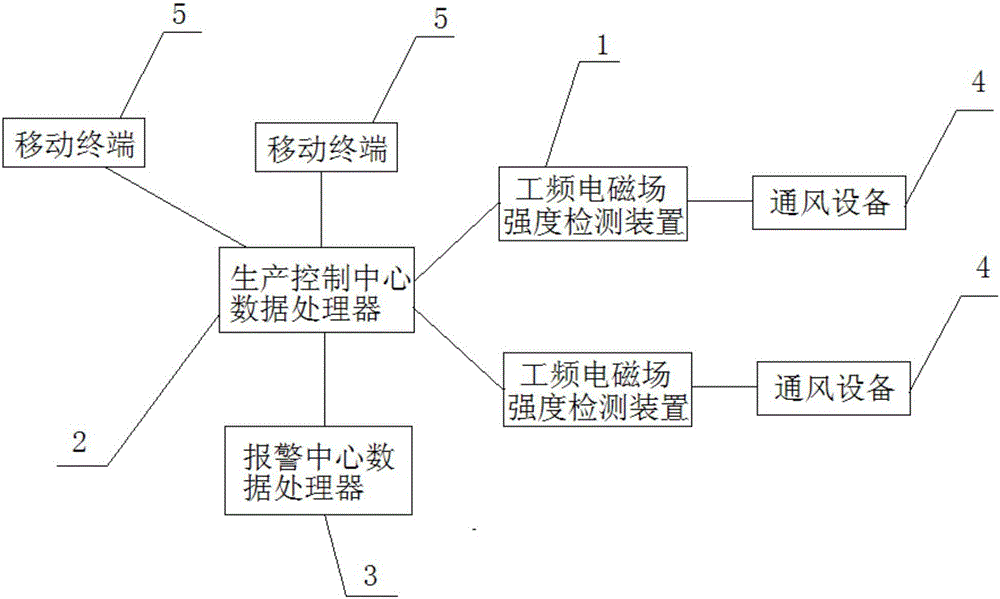

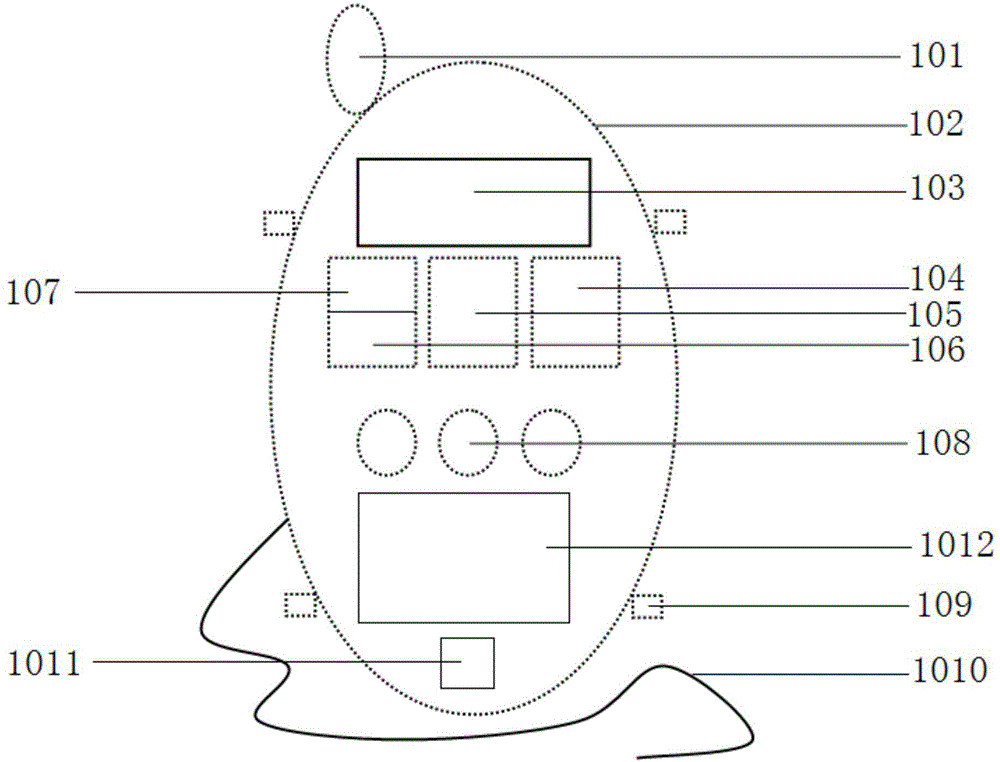

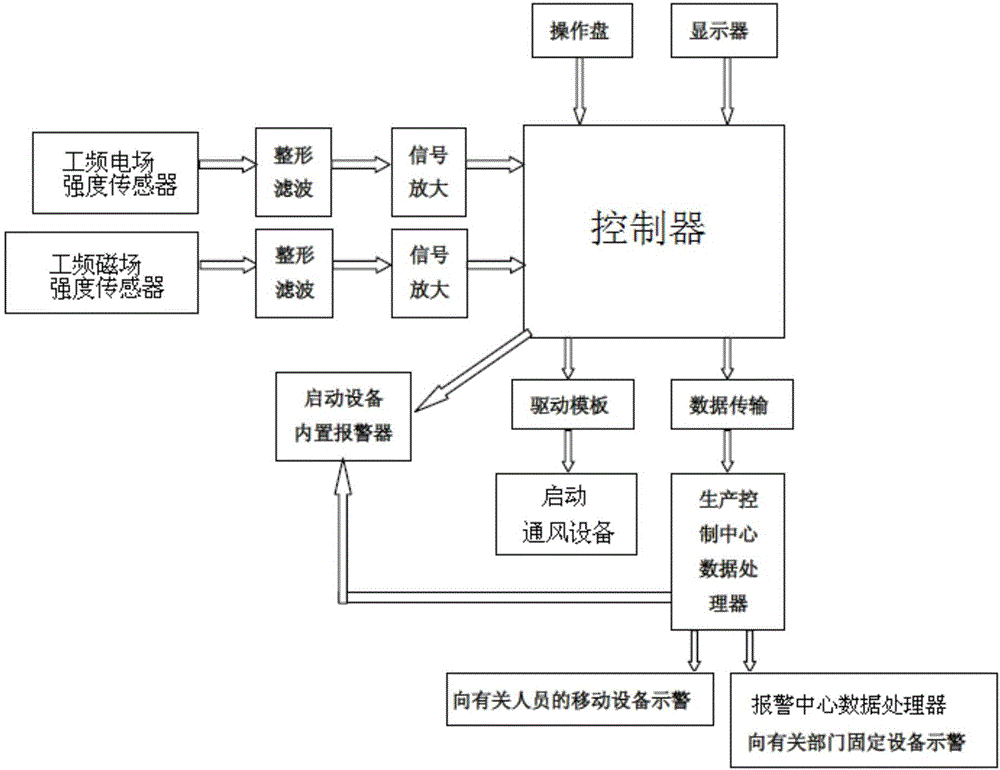

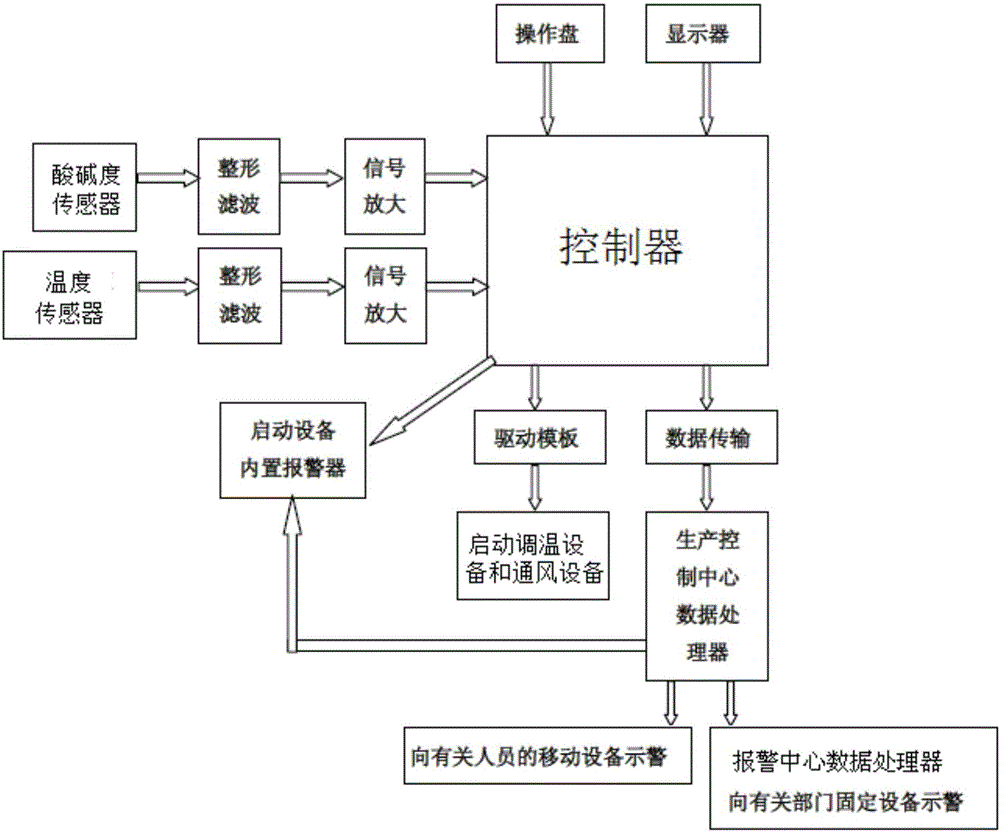

Double-point fixed type power frequency electromagnetic field intensity combined alarm system and operation method thereof

ActiveCN106680596AReduce inspectionReduce frequencyTransmission systemsElectromagentic field characteristicsContact timeElectromagnetic field

The invention provides a double-point fixed type power frequency electromagnetic field intensity combined alarm system and an operation method thereof, and belongs to the technical field of power frequency electromagnetic field intensity monitoring and alarming. The system comprises a power frequency electromagnetic field intensity detection device, a production control center data processor, an alarm center data processor, a ventilation device and a mobile terminal. According to the invention, inspection and onsite working frequency of workers can be reduced; occupational diseases of the workers, and contact time and contact intensity of harmful factors are reduced; alarms are timely given out, thereby facilitating timely maintenance of devices and increasing of service lifetime of the devices, it is ensured that devices can be in good use states for a long time, shut-down overhaul frequency is reduced and safe production time is increased; casualty accidents of personnel are reduced; an accident and abnormal situation database is established, so cost required for the accidents and the abnormities is reduced and disposal time is reduced; and through the accumulation of big data, data abnormity reasons are judged, load conditions of the devices are known and when parts of the devices are in a high-load condition for a long term, companies can be reminded for increasing the number of the devices, so load of the single device can be reduced.

Owner:JILIN ELECTRIC POWER RES INST +2

Internet based commanding and dispatching method

InactiveCN107274022AReduce disposal timeImprove command and dispatch efficiencyForecastingResourcesGeographic siteGeolocation

The invention discloses an Internet based commanding and dispatching method. The Internet based commanding and dispatching method comprises the steps that first, a traffic police division information platform performs fuzzy matching on a geographical position in traffic warning condition and mass Internet points of interest (POI), and selects an accurate road segment position from a data result of fuzzy matching so as to perform warning condition positioning; second, the traffic police division information platform determines a warning condition disposition police officer according to the warning condition positioning; third, a warning condition receiving terminal of the warning condition disposition police officer receives the traffic warning condition and the warning condition positioning information, and the warning condition disposition police officer checks the traffic warning condition and the warning condition positioning information; fourth, the warning condition receiving terminal sends geographical position information of the warning condition disposition police officer to the traffic police division information platform; fifth, the traffic police division information platform sends optimal police sending route information to the warning condition receiving terminal of the warning condition disposition police officer; and sixth, the warning condition disposition police officer feeds back warning condition disposition conditions through the warning condition receiving terminal.

Owner:BEIJING E HUALU INFORMATION TECH

Bridge potential safety hazard troubleshooting informatization management system and application method thereof

PendingCN112651644AInhibit deteriorationShorten closing timeGeometric CADResourcesMobile appsInformatization

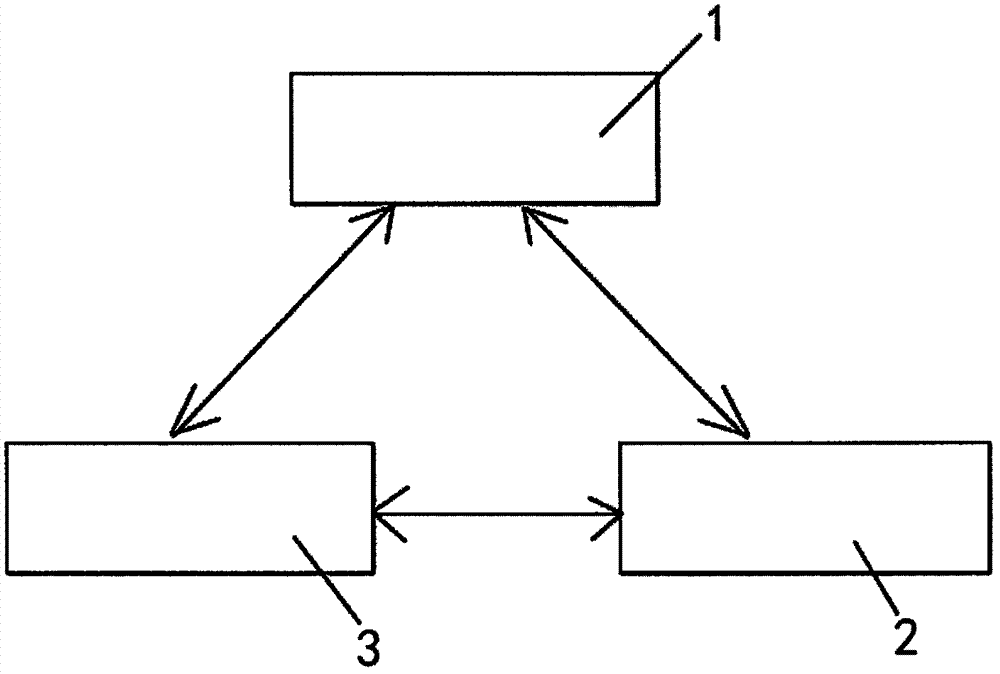

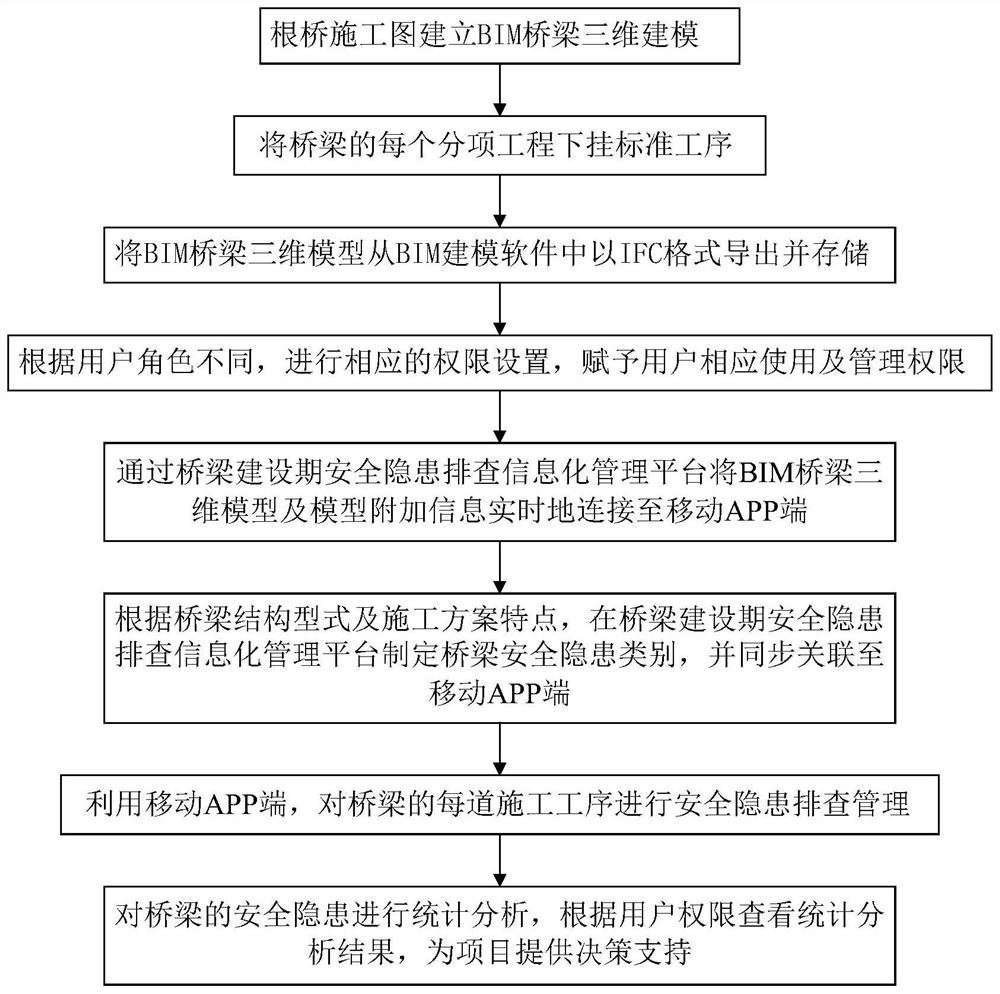

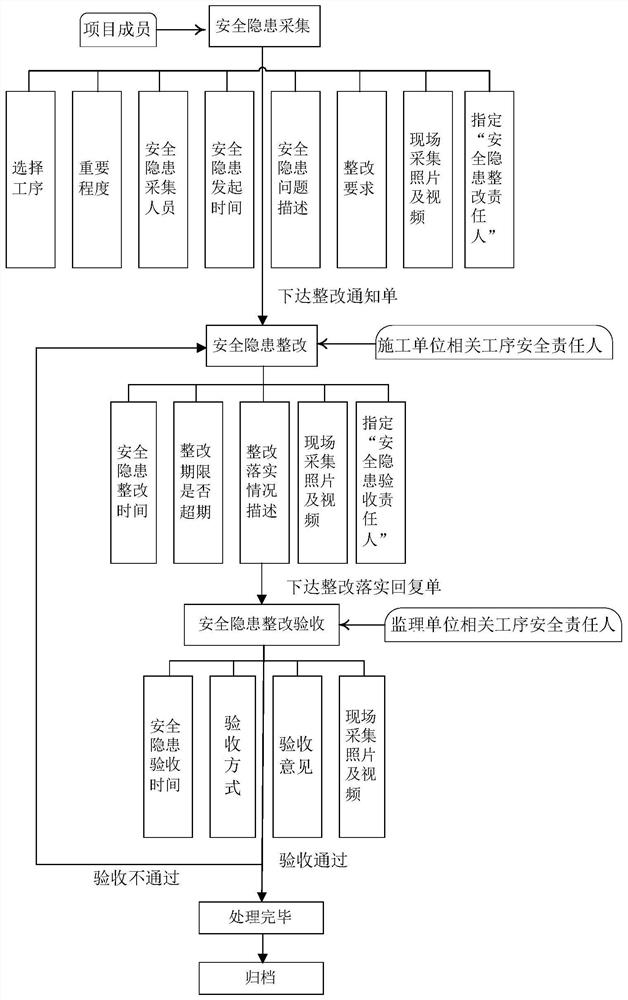

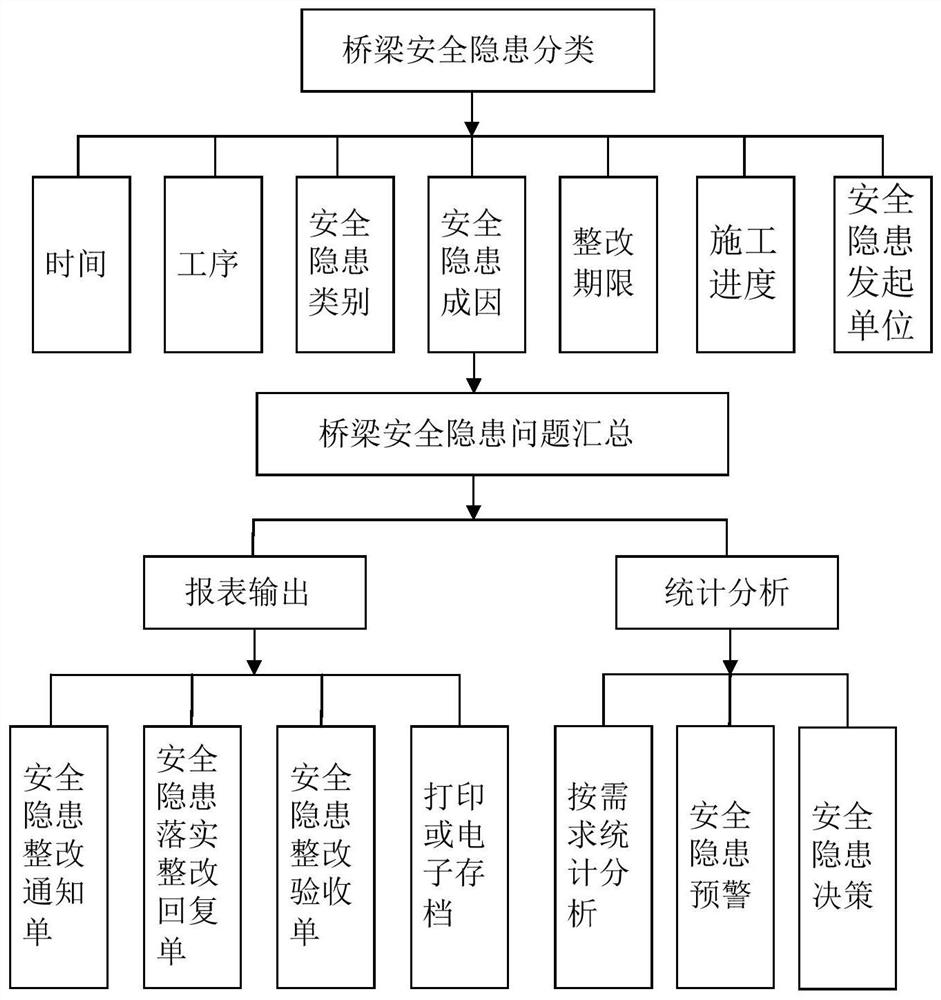

The invention discloses a bridge potential safety hazard troubleshooting informatization management system and an application method thereof. The bridge potential safety hazard troubleshooting informatization management system comprises: a bridge potential safety hazard troubleshooting informatization management platform and a mobile APP terminal; The management platform can import a BIM bridge three-dimensional model and additional information, can perform permission setting according to different user roles, can connect a BIM bridge three-dimensional model and additional information the mobile APP terminal in real time, and can formulate and synchronously associate bridge potential safety hazard categories according to bridge structure types and construction scheme characteristics to the mobile APP terminal; the mobile APP terminal can perform potential safety hazard troubleshooting management (potential safety hazard collection, rectification and acceptance) on each construction process of the bridge on the construction site of the bridge; based on the BIM technology, informationized and closed-loop management is formed, the bridge potential safety hazard disposal time is shortened, the potential safety hazard disposal capacity is improved, and tracking and tracing can be achieved; and the system also has a statistical analysis function, and can check the statistical analysis result according to the user permission to provide decision support for the project.

Owner:CHONGQING UNIV +1

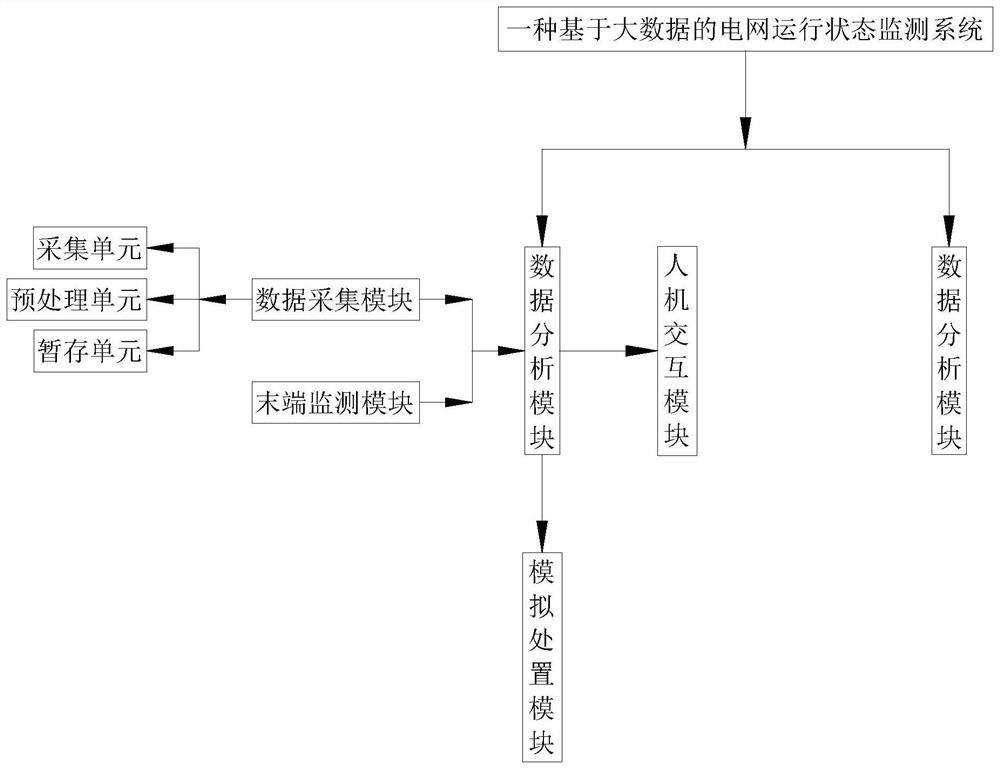

Power grid operation state monitoring system based on big data

PendingCN112541603AImprove stabilityEnsure safetyForecastingFault location by conductor typesElectric power systemData acquisition

The invention belongs to the technical field of power system monitoring, and particularly relates to a power grid operation state monitoring system based on big data, which comprises a data acquisition module, a data analysis module and a data storage module, the data acquisition module comprises an acquisition unit used for acquiring state data at a power grid operation node, after the data acquisition module acquires state data, the data is uploaded to the data analysis module through a 5G network, the data analysis module is used for analyzing the received state data by adopting a flow calculation mode and establishing a prediction model according to the received state data, the data analysis module analyzes the prediction model, predicts the operation state of the power grid in a shorttime in the future to obtain predicted operation data, and performs early warning on possible abnormal operation of the power grid in advance, the data acquired by the data acquisition module is stored in the data storage module, and abnormality can be discovered in advance and early warning can be performed so that operation safety of the power grid can be enhanced.

Owner:丁昆浩

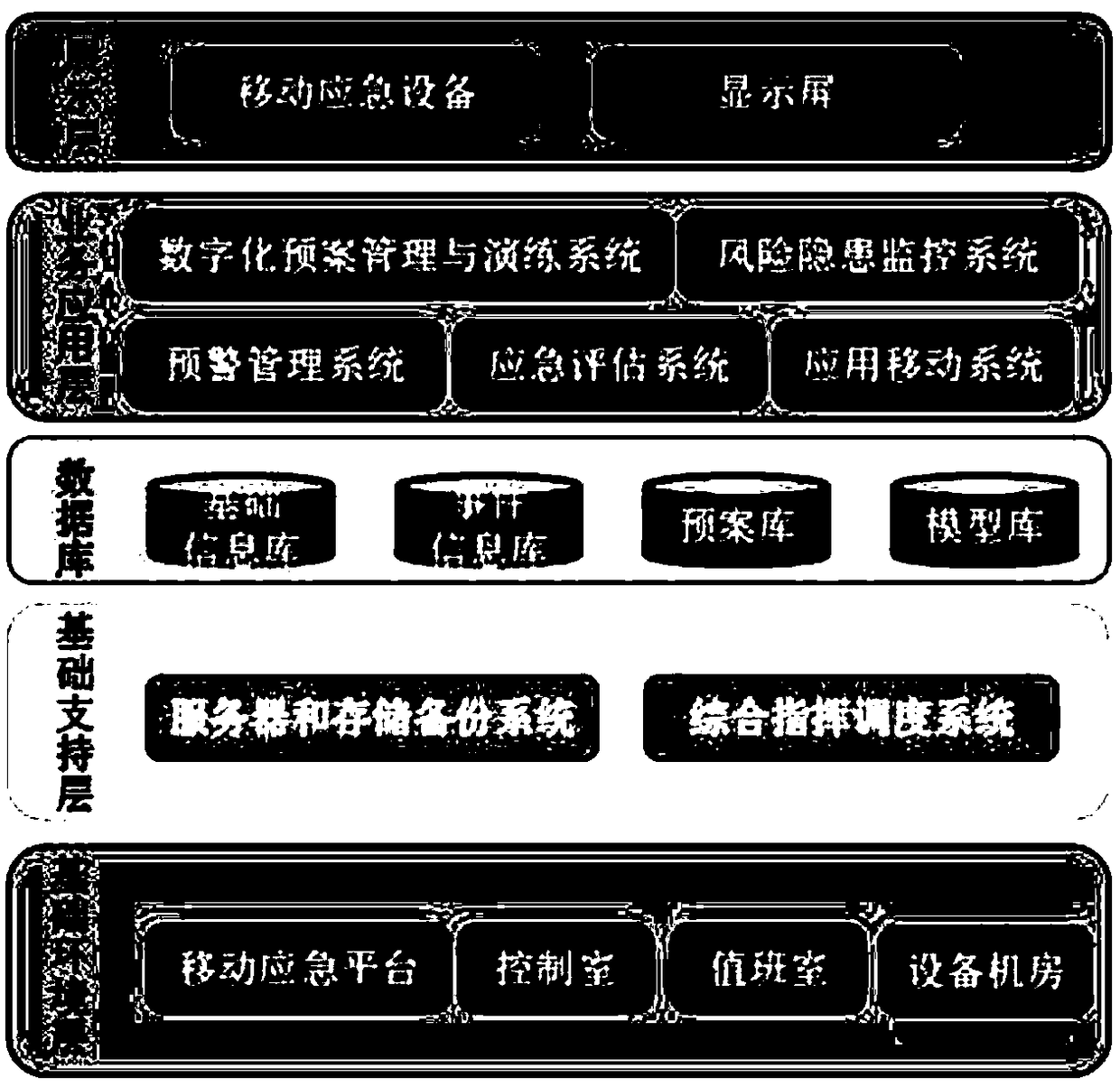

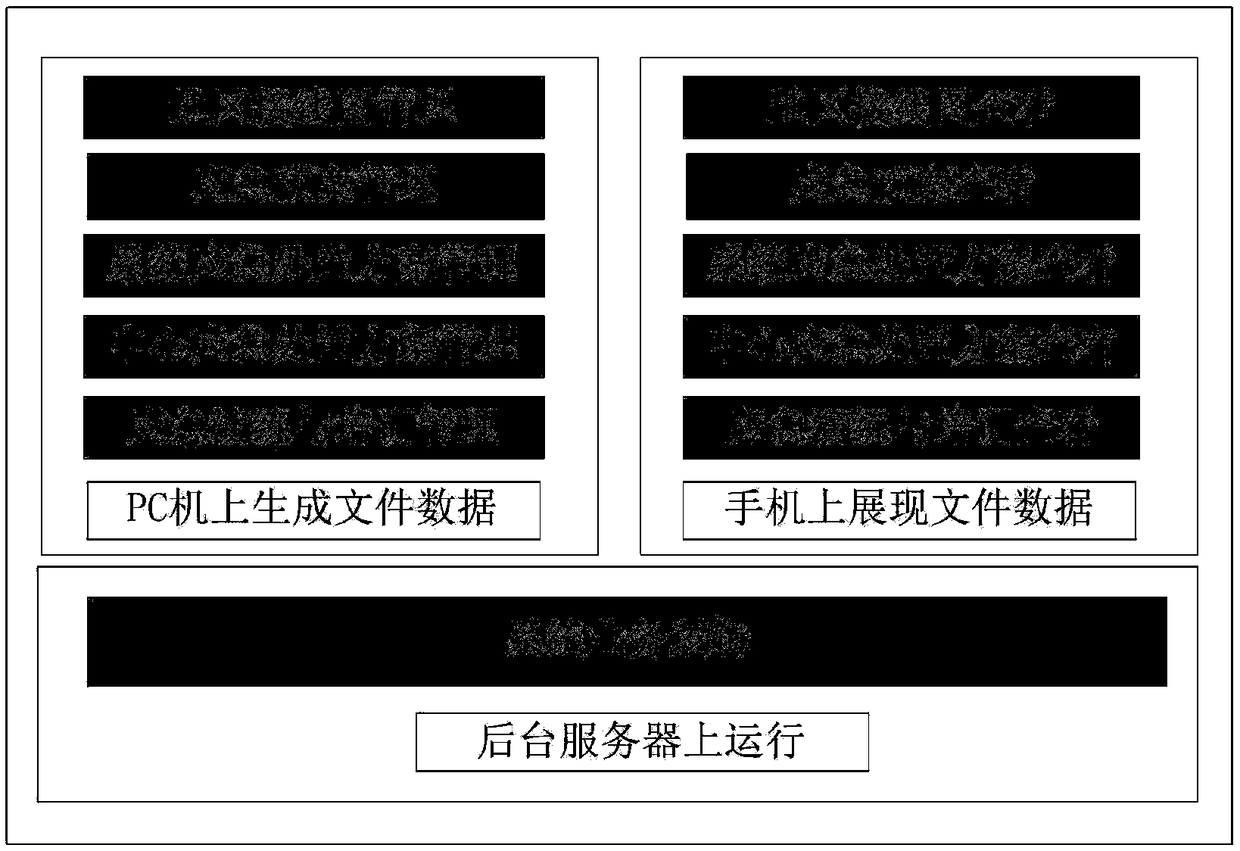

Mobile platform system of emergency plan and disposal scheme

The invention discloses a mobile platform system of an emergency plan and a disposal scheme, and the system includes an interface presentation layer, a business application layer, a database and an infrastructure support layer. The system of the invention can ensure that the emergency command and emergency disposal department and personnel of the dispatching center timely and quickly grasp the latest emergency plan and the emergency disposal scheme content, and provides detailed information for emergency command and emergency disposal, wiring diagrams of various regions are added to an emergency disposal management software system, and the function of using the emergency disposal scheme and emergency plan at any time, at anywhere, conveniently and quickly can be provided for emergency command and emergency disposal, the emergency command and emergency disposal capability is improved, the power grid risks and the disposal time of power grid accidents are reduced, and the reliability ofpower grid power supply is improved.

Owner:GUIZHOU POWER GRID CO LTD

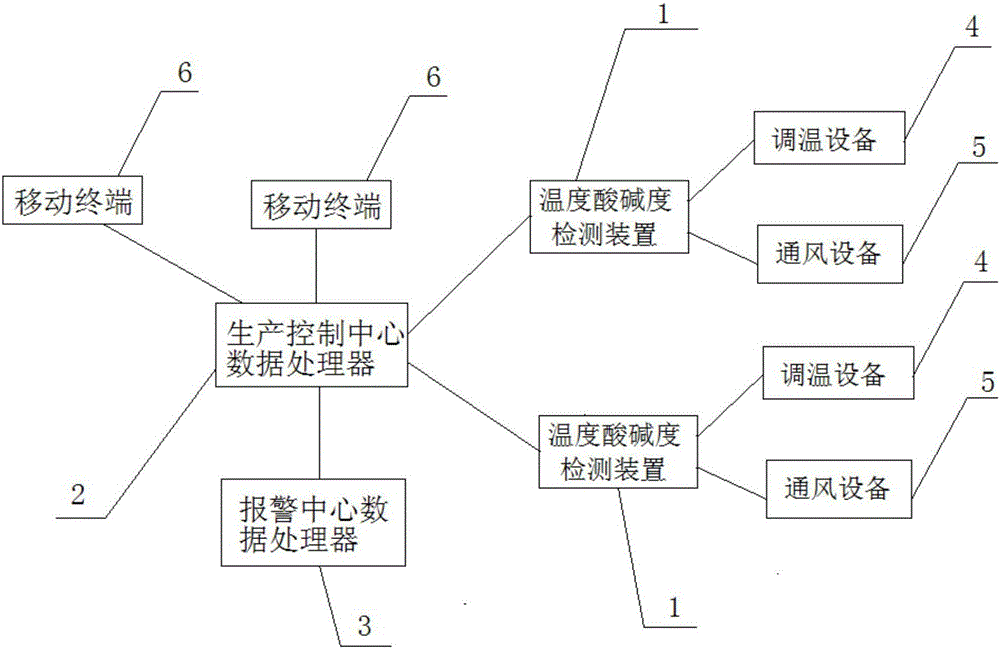

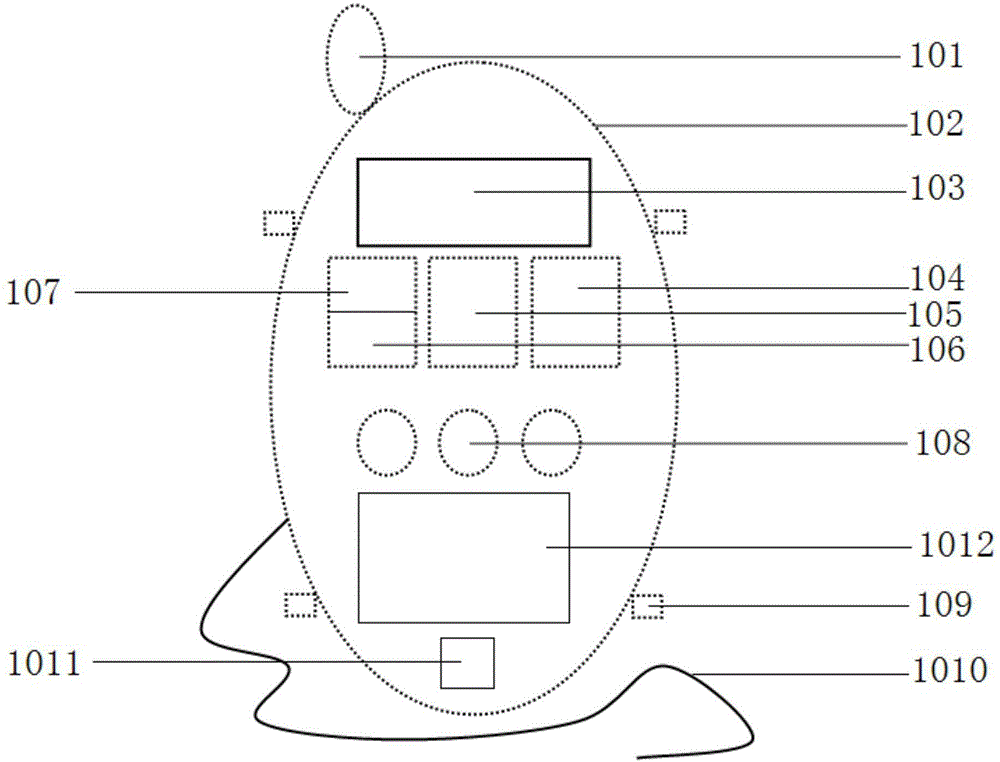

Two-point fixed-type temperature-PH value combined alarming system and operation method thereof

ActiveCN106596850AReduce inspectionShorten the timeThermometer applicationsSimultaneous control of multiple variablesContact timeComputer terminal

The invention provides a two-point fixed-type temperature-PH value combined alarming system and an operation method thereof, and belongs to the technical field of temperature-PH value monitoring and alarming. The system comprises a temperature-PH value detection device, a production control center data processor, an alarming center data processor, a temperature regulating device, a ventilation device and a mobile terminal. According to the system, the inspection and field operation frequency of operators can be decreased, the occupational disease harmful factor contact time of the operators can be shortened, and the occupational disease harmful factor contact intensity of the operators can be reduced; in-time alarming is conducted, in-time maintenance of the devices is promoted, the service life of an instrument is prolonged, it is guaranteed that the instrument keeps a good using state for a long time, the stopping overhauling frequency is decreased, and the safe production time is prolonged; personal casualty accidents are reduced; an accident and abnormal condition database is established, expenditures needed by the accidents and abnormity are reduced, and the handling time is shortened; by means of big data accumulation, the data abnormity causes are judged, the load conditions of the devices are known, and when part of the devices are in a high-load condition, the system can remind a company to increase the device number to reduce the load of the single device.

Owner:JILIN PROVINCE ELECTRIC POWER RES INST OF JILIN ELECTRIC POWER CO LTD +3

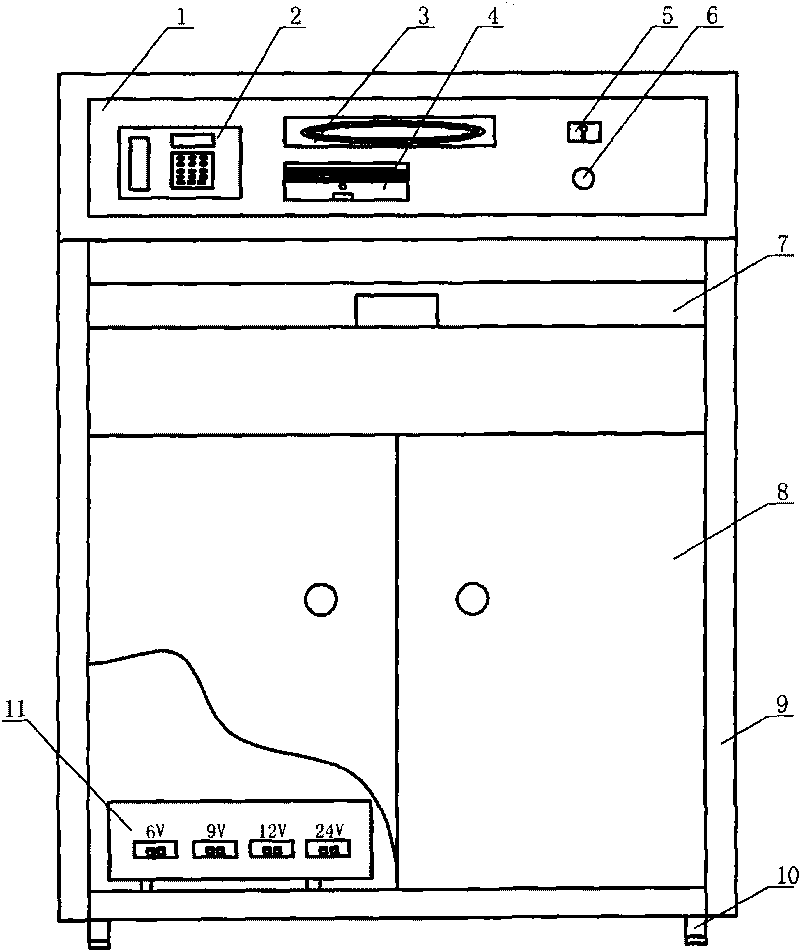

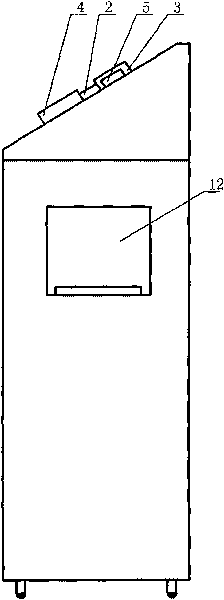

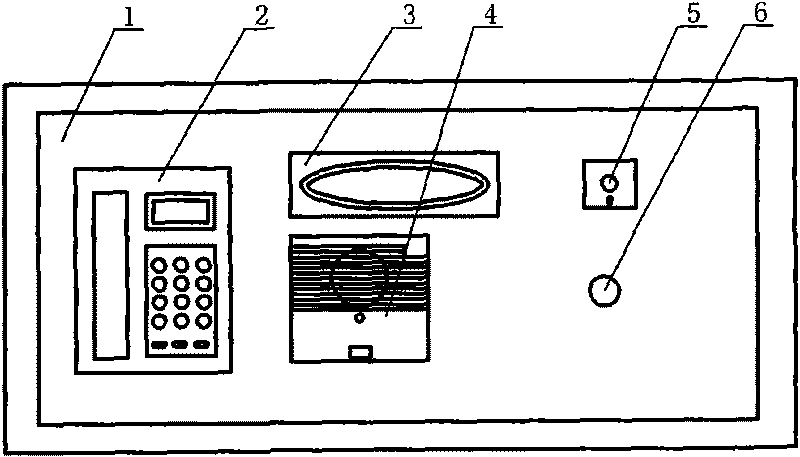

Private network communication integrated system

InactiveCN101753684ADelayed reaction timeReduce disposal timeSubstation equipmentPrivate networkEngineering

The invention relates to a private network communication integrated system. The main technical characteristics of the invention is that the private network communication integrated system comprises a private network phone, a wire intercome, an alarm, a clock and a multifunctional power supply module; all the communication devices are integrally arranged on a mobile control box; and the control box body is fixedly arranged on the upper part of a movable storage box. The private network communication integrated system carries out organic integration on all the device for the private network communication, has scientific and reasonable design, can effectively shorten the handling time of the response, provides support for the rapid response, and is an integrated device which has stronger innovation and is special for the private network.

Owner:天津安铁科技发展有限公司

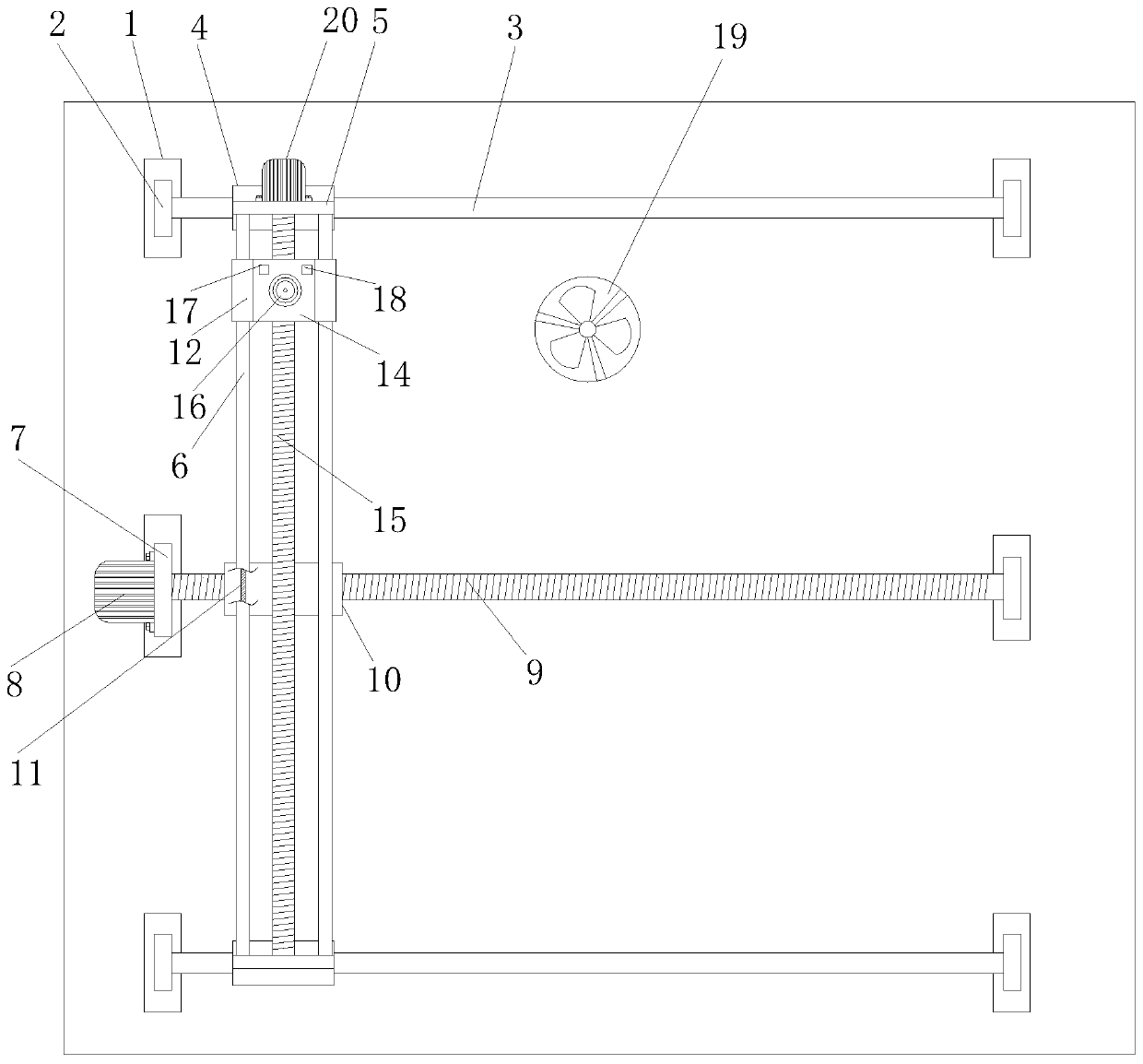

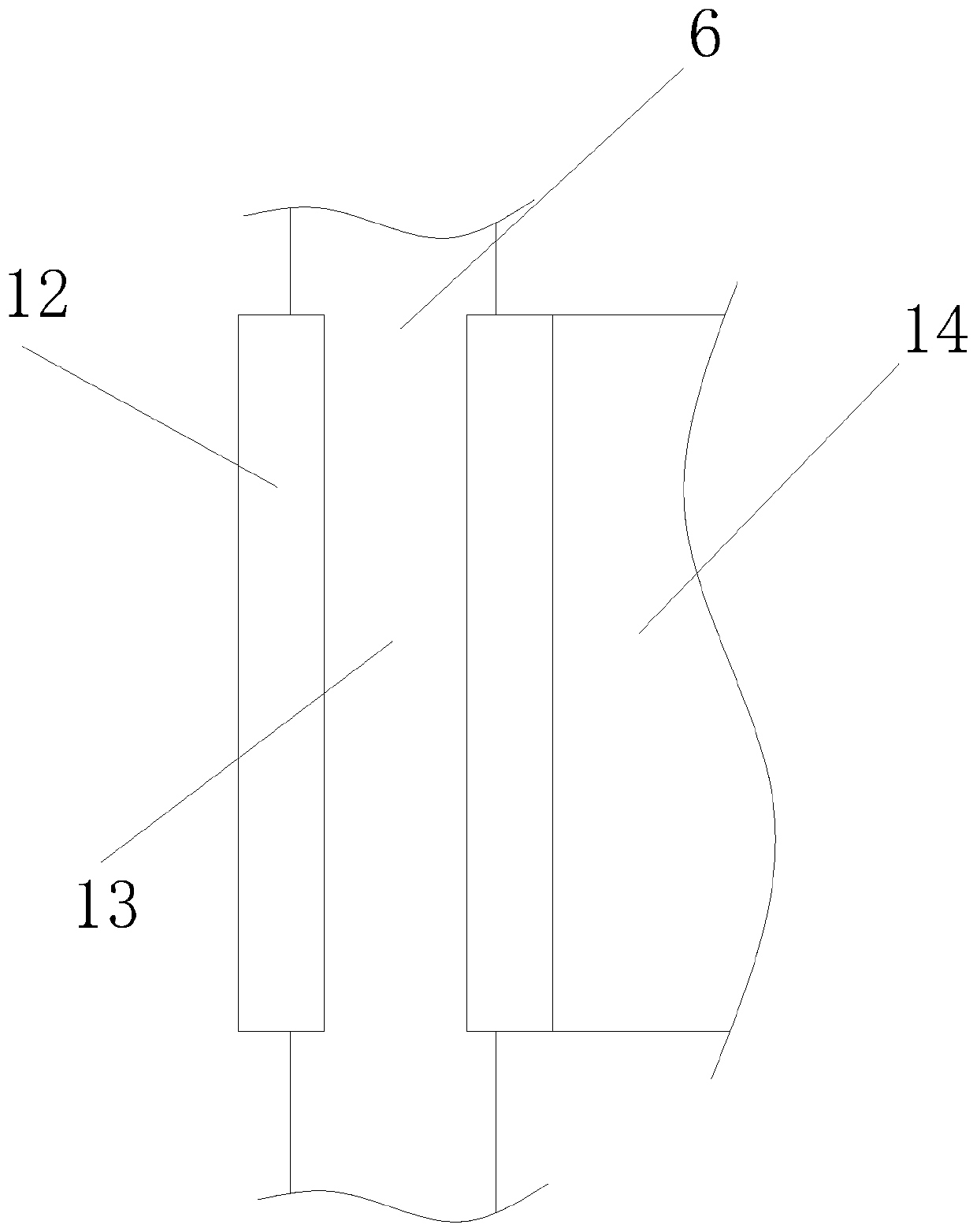

Intelligent power distribution integrated monitoring system based on ubiquitous Internet of Things

PendingCN111371181AReal-time monitoring statusReal-time monitoring of electricity safetyCircuit arrangementsSubstation/switching arrangement cooling/ventilationIntegrated monitoringElectric machine

The invention discloses an intelligent power distribution integrated monitoring system based on the ubiquitous Internet of Things. The system comprises a temperature sensor, a humidity sensor and a camera. The temperature sensor, the humidity sensor and the camera are fixedly installed on the bottom plate, the bottom plate is connected to the vertical guide rod in a sliding mode, the bottom plateis pushed by the vertical motor to ascend and descend through the lead screw, the vertical guide rod is installed on the transverse guide rod in a sliding mode, and the bottom plate is pushed by the transverse motor through the lead screw to move left and right. According to the invention, fault confirmation and disposal time is shortened. Inspection efficiency is improved, and manpower is saved.The system accumulates operation and maintenance big data, analyzes and improves the data.

Owner:国网安徽省电力有限公司广德市供电公司 +1

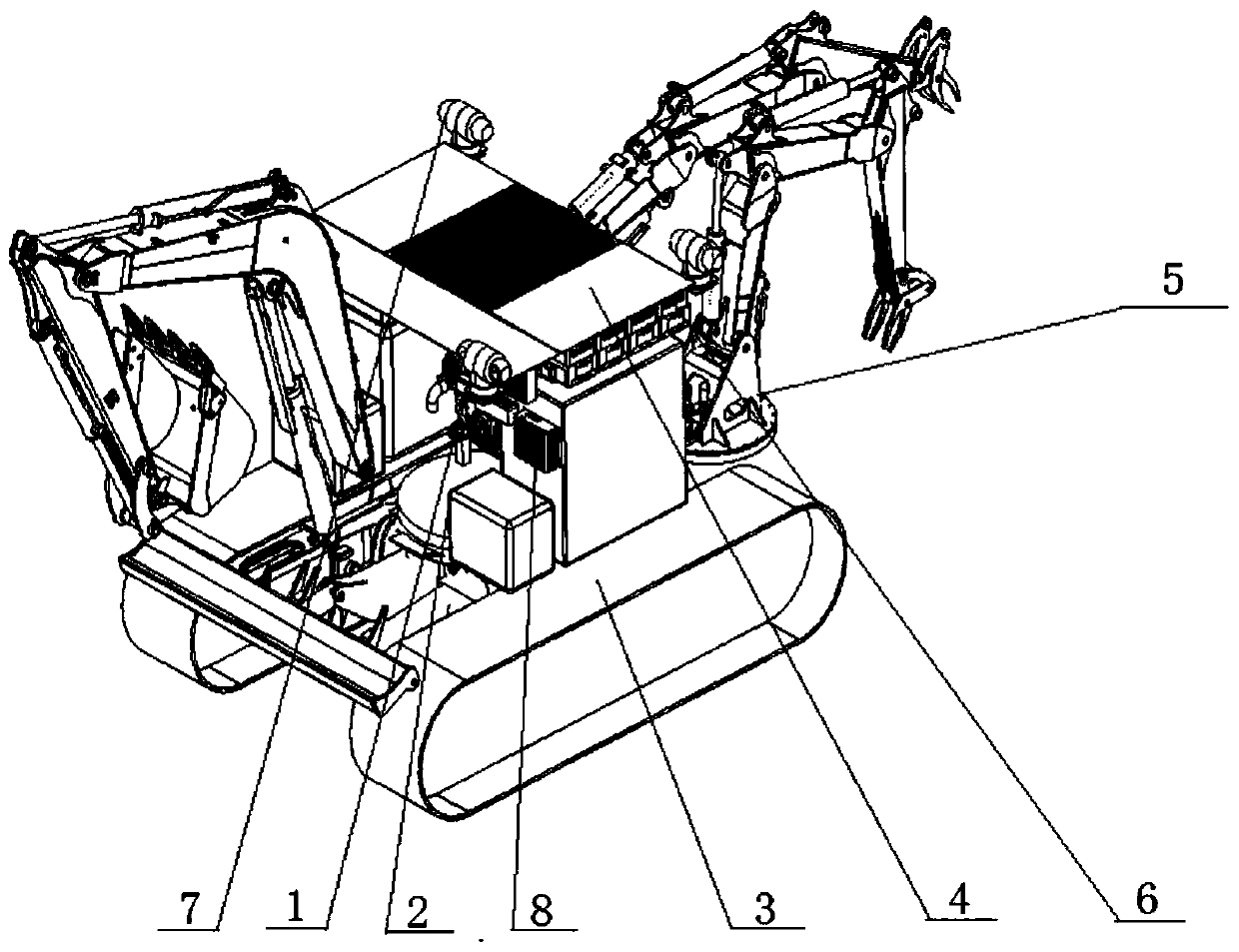

Multifunctional unmanned wrecker

InactiveCN111021442APromote transformation and upgradingPromote innovation and developmentMechanical machines/dredgersRoad cleaningEmergency rescueControl system

The invention discloses a multifunctional unmanned wrecker, and belongs to the technical field of tracked engineering vehicles. The defects and problems of conventional disaster rescue equipment are solved. The multifunctional unmanned wrecker comprises an auxiliary system, an electro-hydraulic hybrid transmission system, action systems, a vehicle body system, operation and hydraulic systems, an electric and control system, an active safety system and a remote control system. The power auxiliary system and the electro-hydraulic hybrid transmission system are arranged on the vehicle body system, the action systems are symmetrically arranged at the two ends of a vehicle body, the operation and hydraulic systems are arranged on the two sides of the vehicle body system, and the active safety system and the remote control system are integrated on the tracked engineering vehicle. Defects of conventional emergency rescue capability can be overcome, and the coverage range of a public safety guarantee system can be effectively expanded.

Owner:HARBIN FIRST MACHINERY GRP

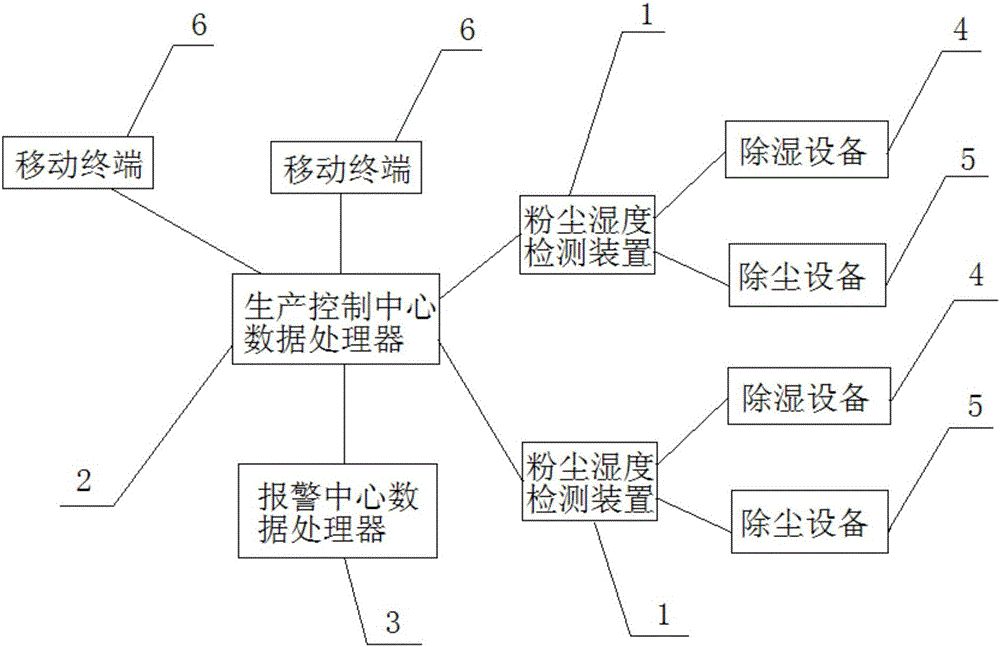

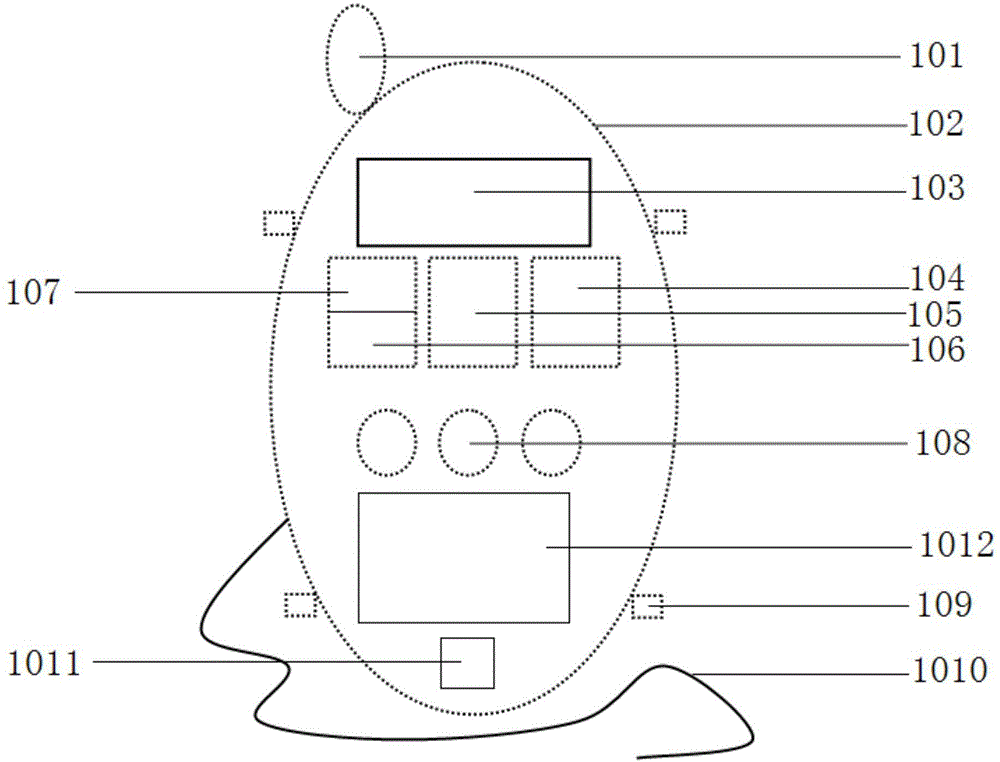

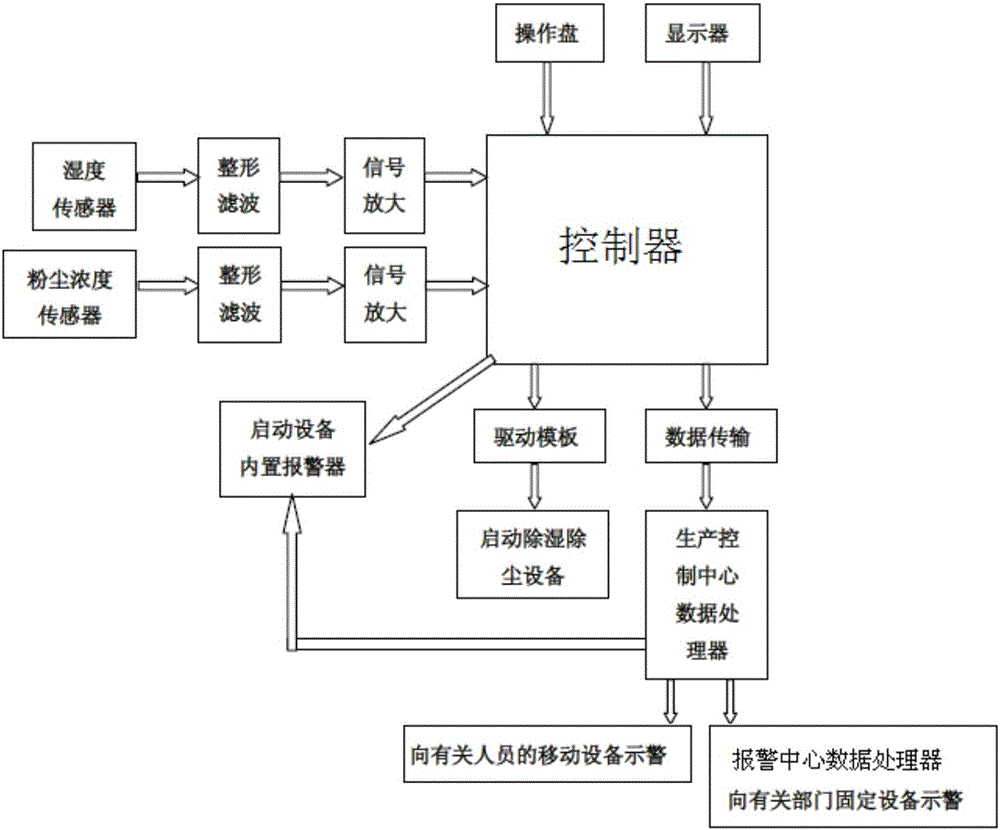

Two-point fixed type dust humidity combined alarm system and operating method thereof

PendingCN106769723AReduce inspectionShorten the timeHumidity controlParticle suspension analysisEngineeringInstrumentation

The invention provides a two-point fixed type dust humidity combined alarm system and an operating method thereof, and belongs to the technical field of dust humidity monitoring and alarming. The system comprises a dust humidity detection device, a production control center data processor, an alarm center data processor, dehumidifying equipment, dust-removing equipment and a mobile terminal. The system provided by the invention can reduce the frequency of polling and field operation of operating workers, and reduce contact the time and contact strength of harmful factors of occupation diseases of the operating workers; the system can give an alarm in time, which is beneficial for repairing equipments in time, prolonging the service life of an instrument, ensuring that the instrument keeps a good usage state for a long time, reducing the frequency of shut-down major overhaul, and increase the time of safe production; personnel casualty accidents are reduced; an accident and abnormal condition data base is established, the funds needed by accidents and abnormal conditions are reduced, and the handling time is reduced; by virtue of accumulation of big data, the cause of data exception is judged, a load condition of equipment is known, and when part of the equipment is in a high-load condition for a long time, a company can be reminded to increase the number of equipment and reduce the load of individual equipment.

Owner:JILIN ELECTRIC POWER RES INST +2

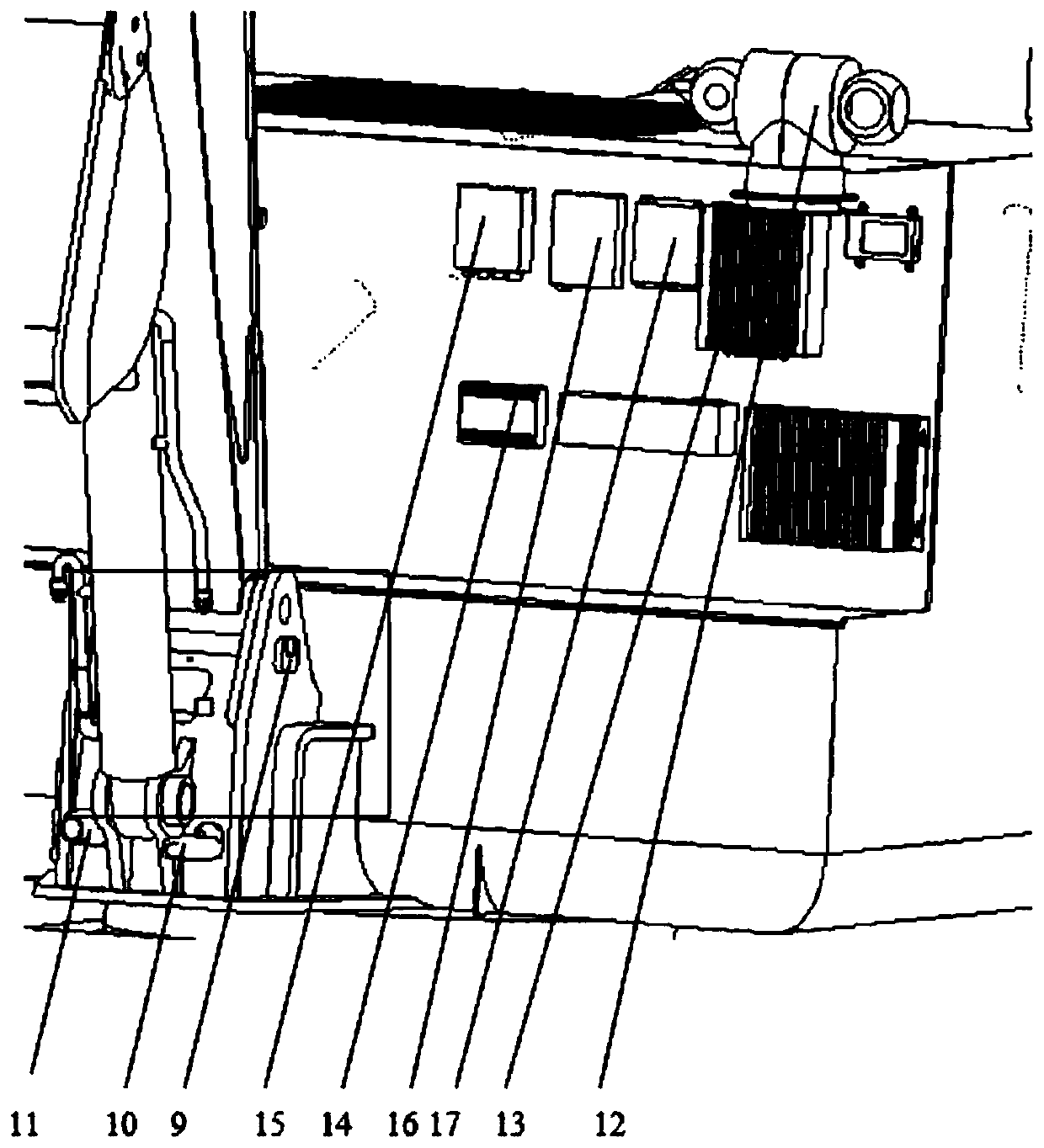

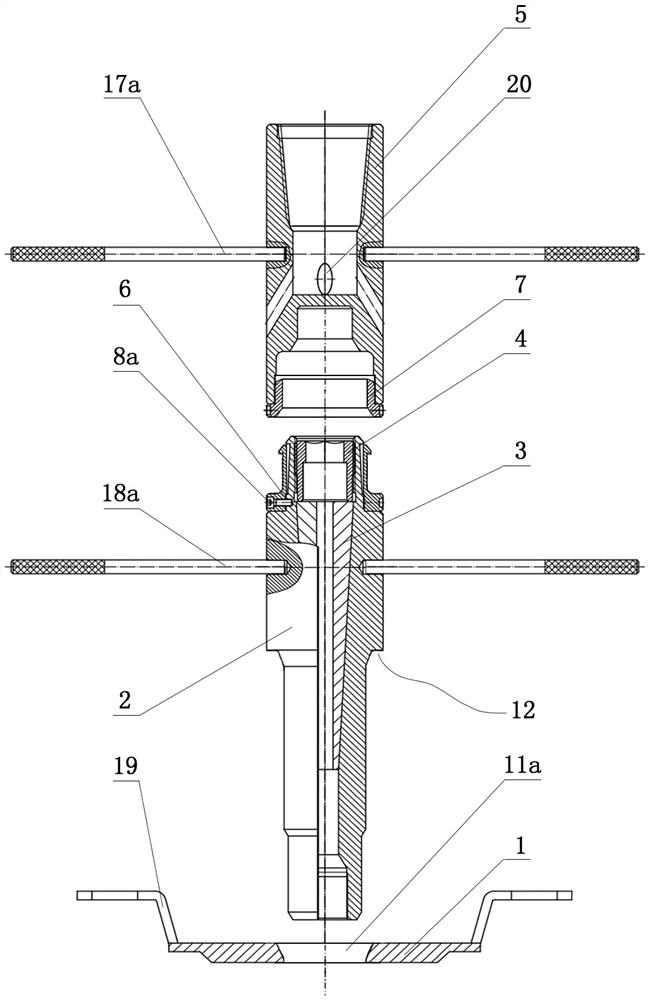

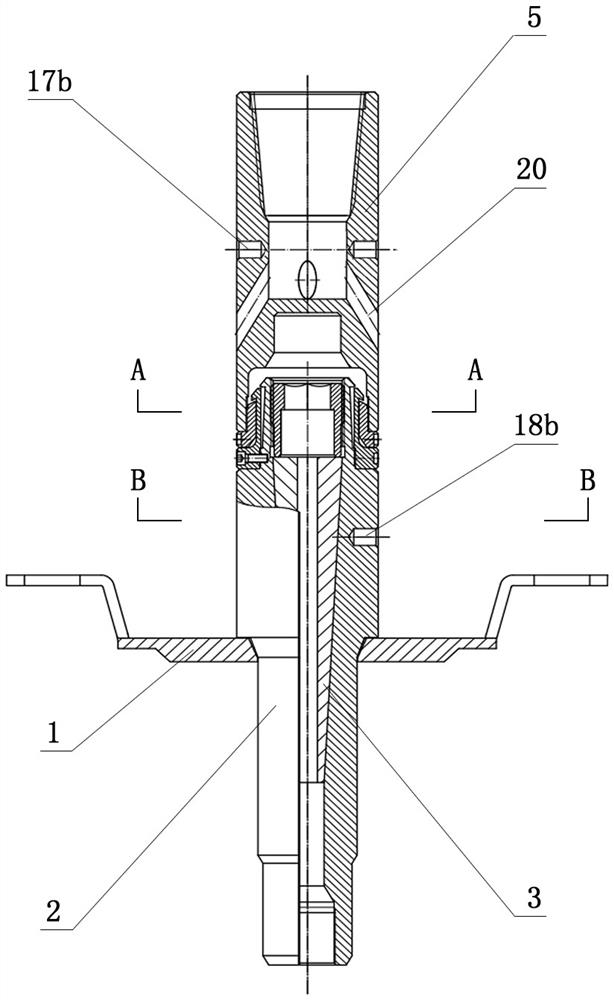

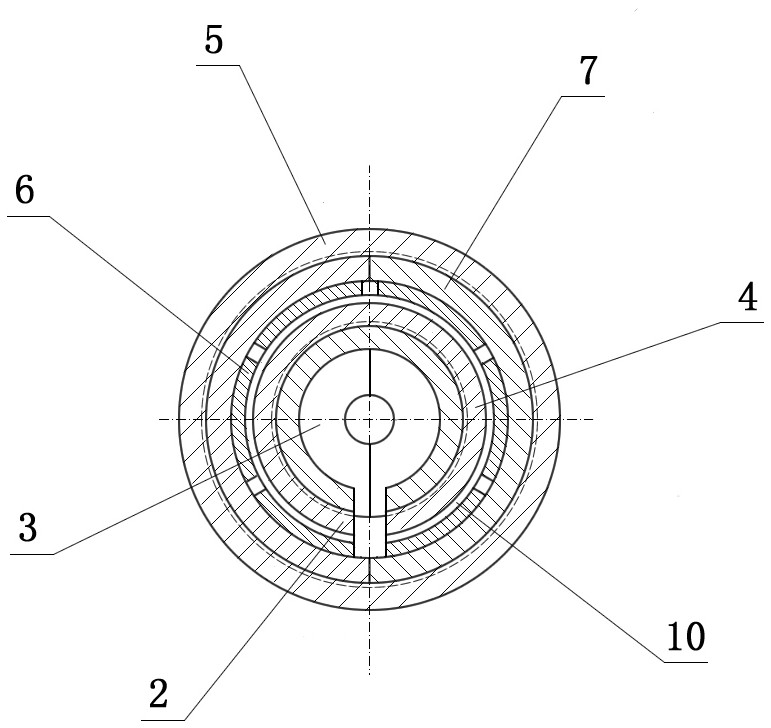

Well control logging cable hanger and tool component and using method thereof

PendingCN111946277AEasy to removeReduce disposal timeDrilling rodsDrilling casingsWell loggingOil field

The invention relates to a well control logging cable hanger and a tool assembly and a using method thereof. The well control logging cable hanger comprises a wellhead chuck, a hanging main body, a split slip, a slip pressing sleeve, a double-female joint, an elastic threaded ring and a split retaining ring; the matched tool component is composed of an ejector rod and a pressing cap, wherein the split retaining ring corresponds to the elastic threaded ring in structure and can be matched with the elastic threaded ring to form an axial elastic clamping matching structure; a logging cable can bequickly and directly hung by using the well control logging cable hanger; an oil well drill rod can be quickly clamped with the hanging main body; and therefore, redundant time for pulling out a logging instrument can be saved, the connecting speed of an oil well drill rod can be increased, the wellhead treatment time of emergency situations in the well logging process can be effectively shortened, the risk corresponding speed in the well logging process can be increased, the risk treatment capacity in the well logging process can be improved, possible risk hidden dangers and possible economic losses are reduced, and a more reliable guarantee is provided for safe production of an oil field.

Owner:MUDANJIANG TIANQING TECH

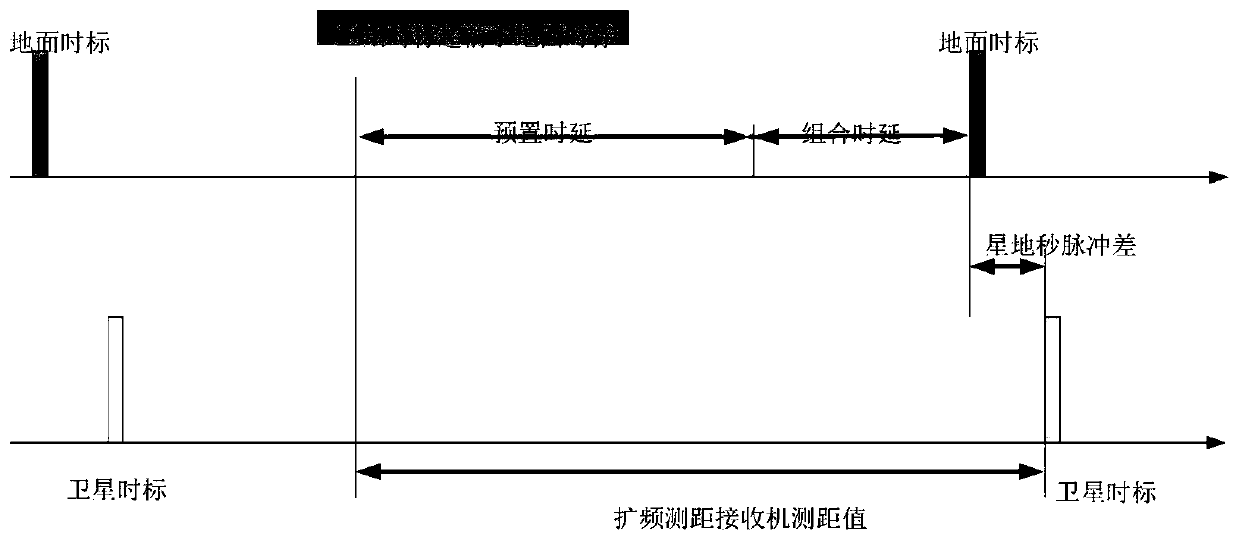

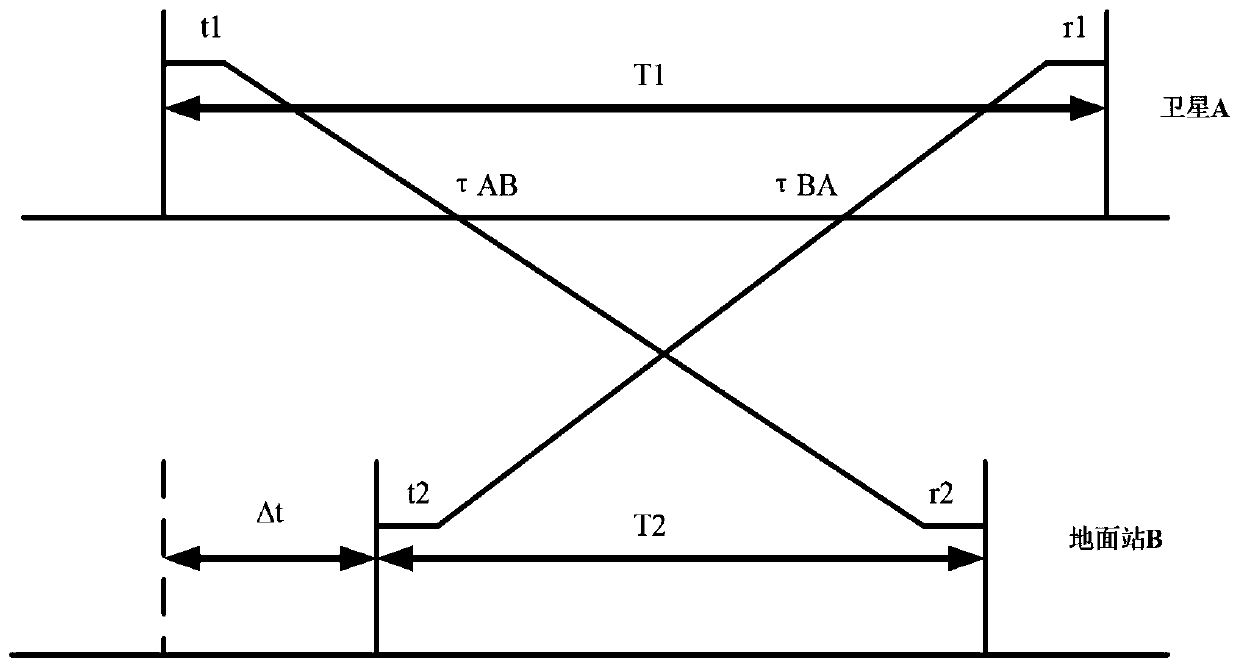

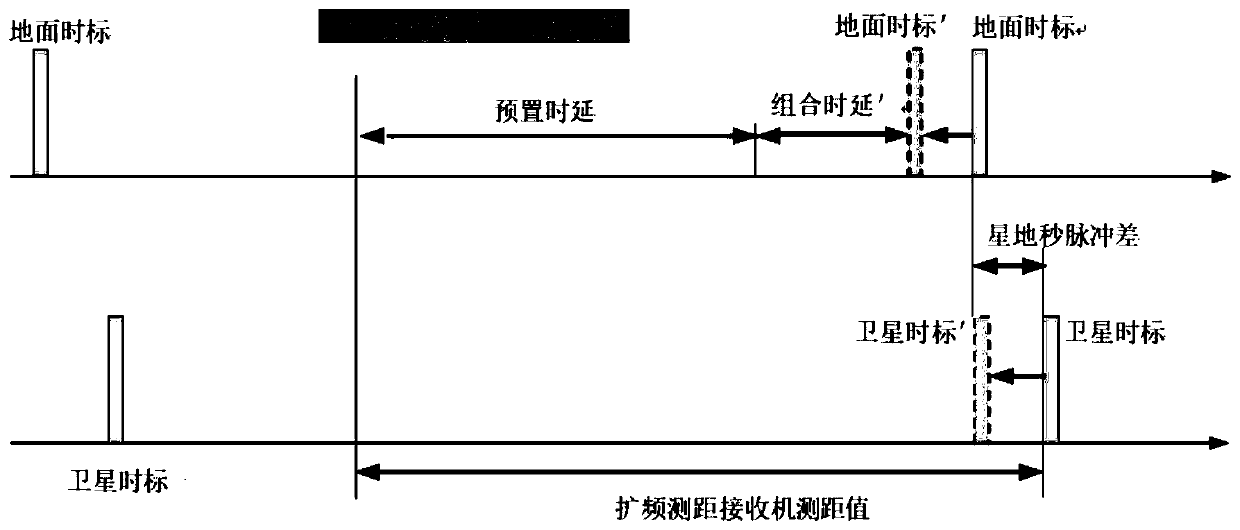

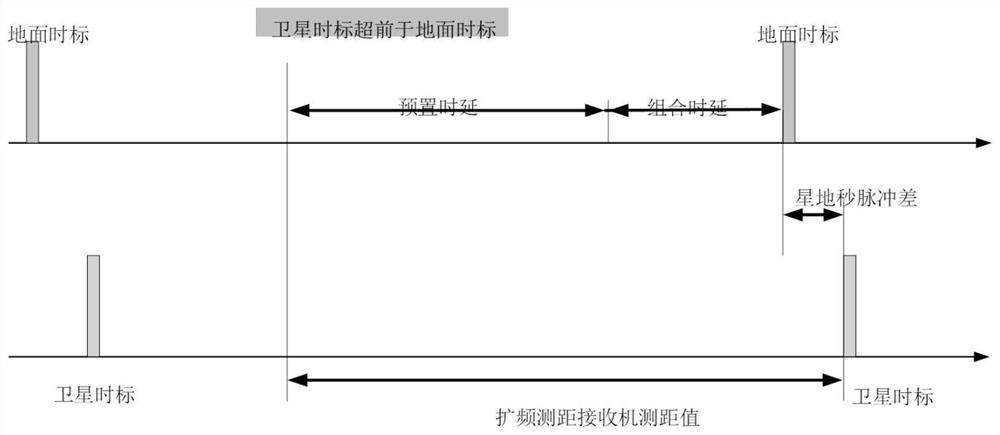

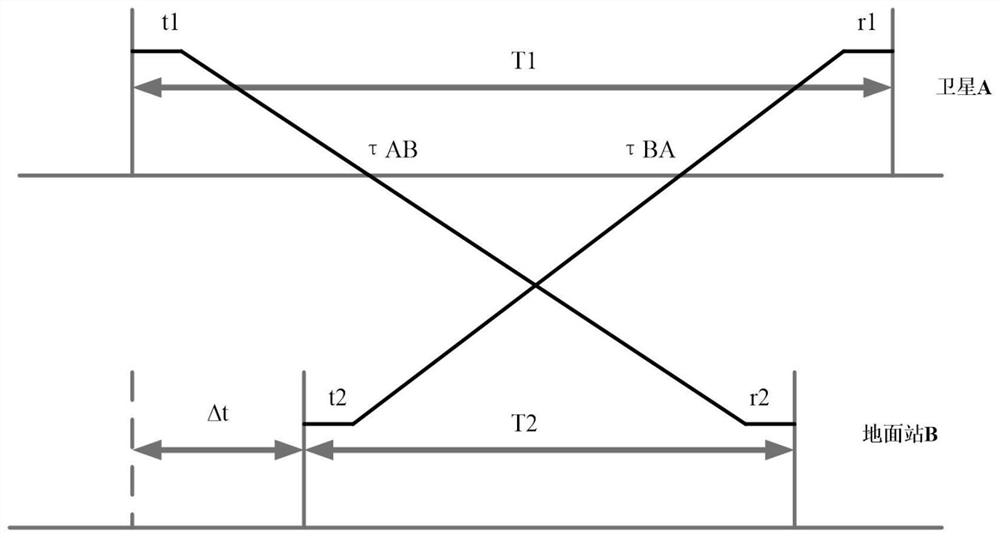

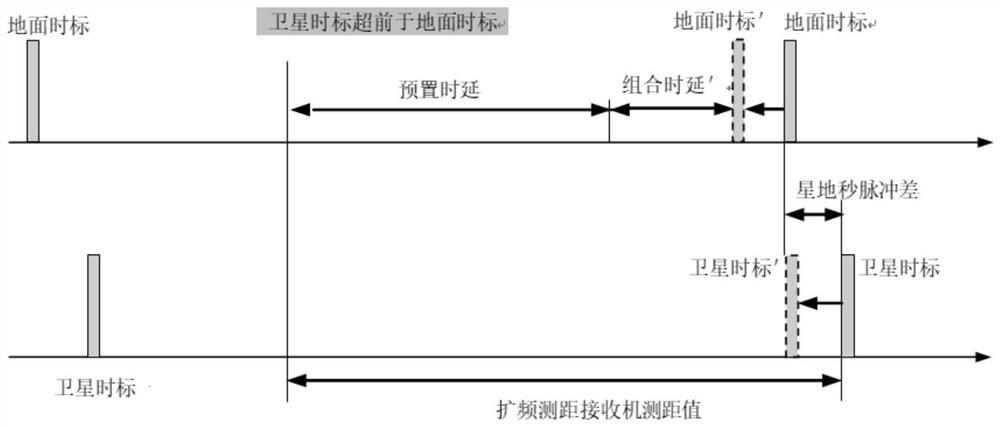

Satellite-ground clock error rapid recovery method realized by using initial synchronization instruction

ActiveCN111431577AReduce disposal timeReduce waiting timeRadio transmissionSatellite radio beaconingTime delaysSpread spectrum

The invention provides a satellite-to-ground clock error rapid recovery method realized by using an initial synchronization instruction, which comprises the following specific steps: after a satellitesingle machine is turned on and off or reset, sending the initial synchronization instruction to a satellite to complete satellite-to-ground initial synchronization; obtaining a distance measurementvalue T1 downloaded by a satellite spread spectrum distance measurement receiver and a distance measurement value T2 received by ground equipment; calculating a satellite-ground clock error delta t based on the distance measurement value T1 and the distance measurement value T2; and reversely adjusting the time delay of the ground equipment emission channel by utilizing the calculated delta t, sending the initial synchronization instruction to the satellite again, adjusting the satellite-ground time scale difference delta t backwards by the satellite time scale, recovering the time delay of the ground equipment emission channel to an initial value, and aligning the adjusted satellite time scale with the ground time scale at any time. The method can achieve the quick synchronization of thesatellite-ground time after the on-orbit startup and shutdown or resetting of the satellite.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

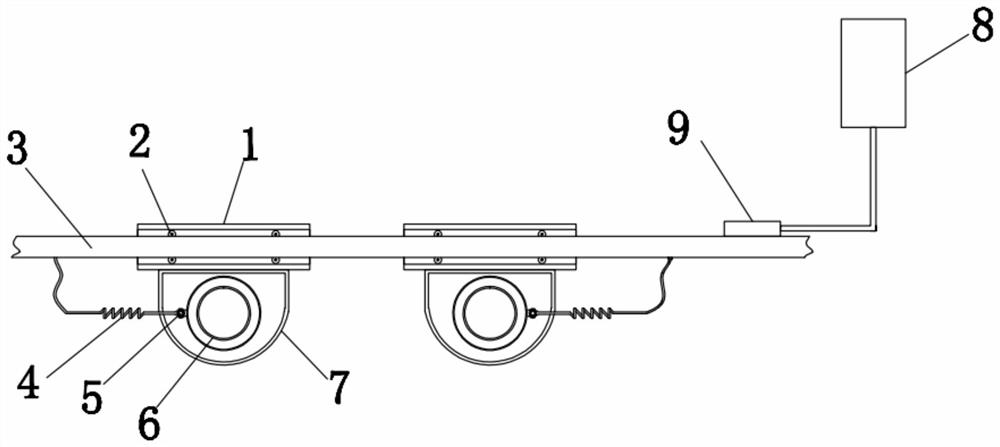

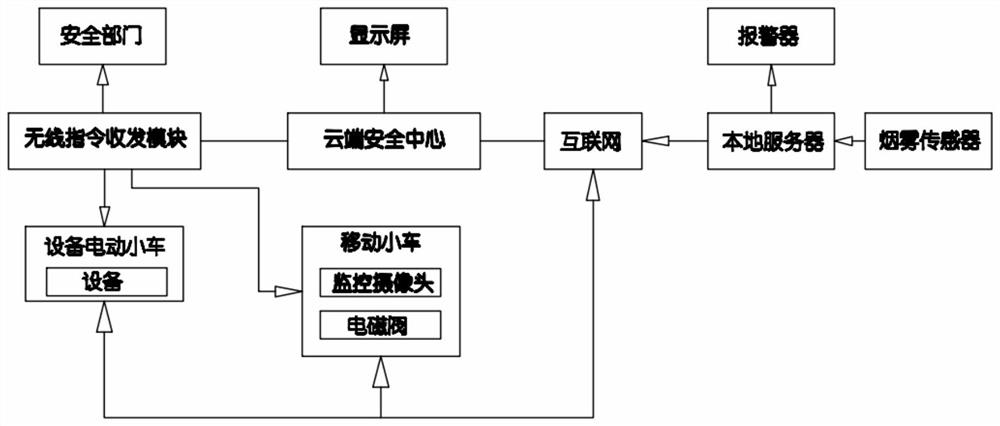

Safety monitoring, early warning and emergency disposal system based on industrial internet

PendingCN114244881AAvoid missing processingAccurate handlingClosed circuit television systemsTransmissionRemote controlThe Internet

The invention discloses an industrial internet-based security monitoring, early warning and emergency disposal system, which comprises a local server based on industrial internet operation, the local server is provided with a plurality of smoke sensors, and the plurality of smoke sensors are distributed in a plurality of devices arranged side by side. The smoke sensor is used for detecting smoke in the surrounding environment of the equipment and transmitting a feedback signal to the local server, the local server is accessed to the cloud security center through the industrial internet, and the cloud security center controls movement of multiple pieces of equipment and the monitoring camera at the local server end through the wireless instruction receiving and transmitting module. According to the invention, the industrial internet on the site is utilized to upload possible conditions to the cloud at the first time, and the cloud security center is utilized to perform remote control and quickly perform early warning and disposal, so that the problem position of the equipment can be better exposed, the visual angle is more comprehensive, and the emergency disposal capability is stronger.

Owner:深圳建安润星安全技术有限公司

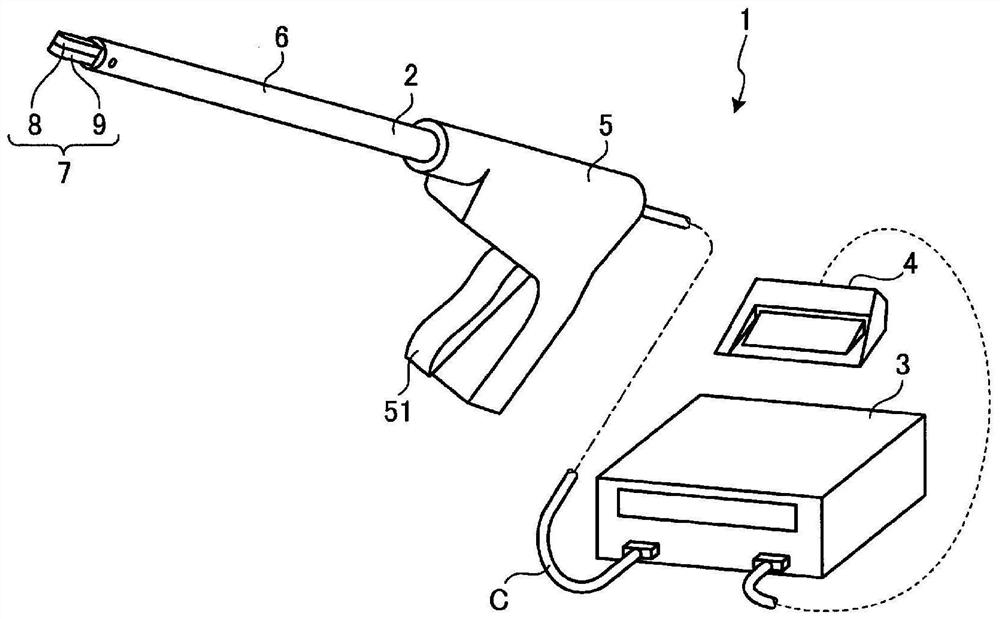

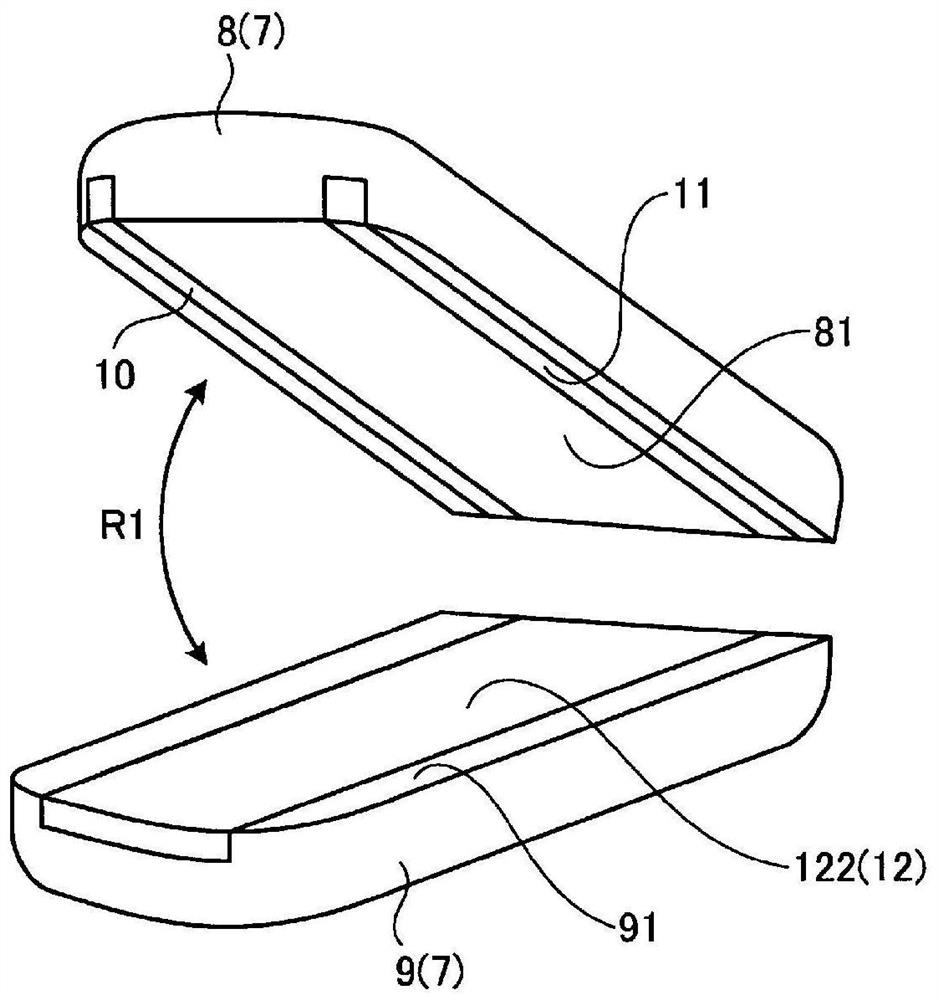

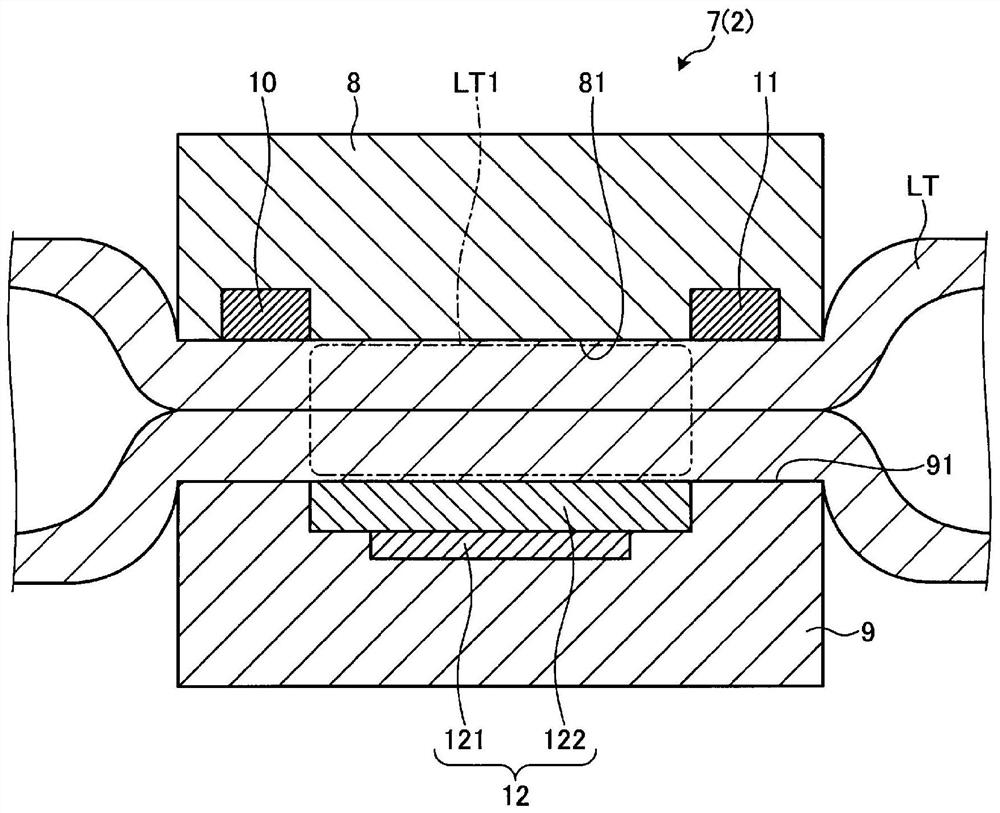

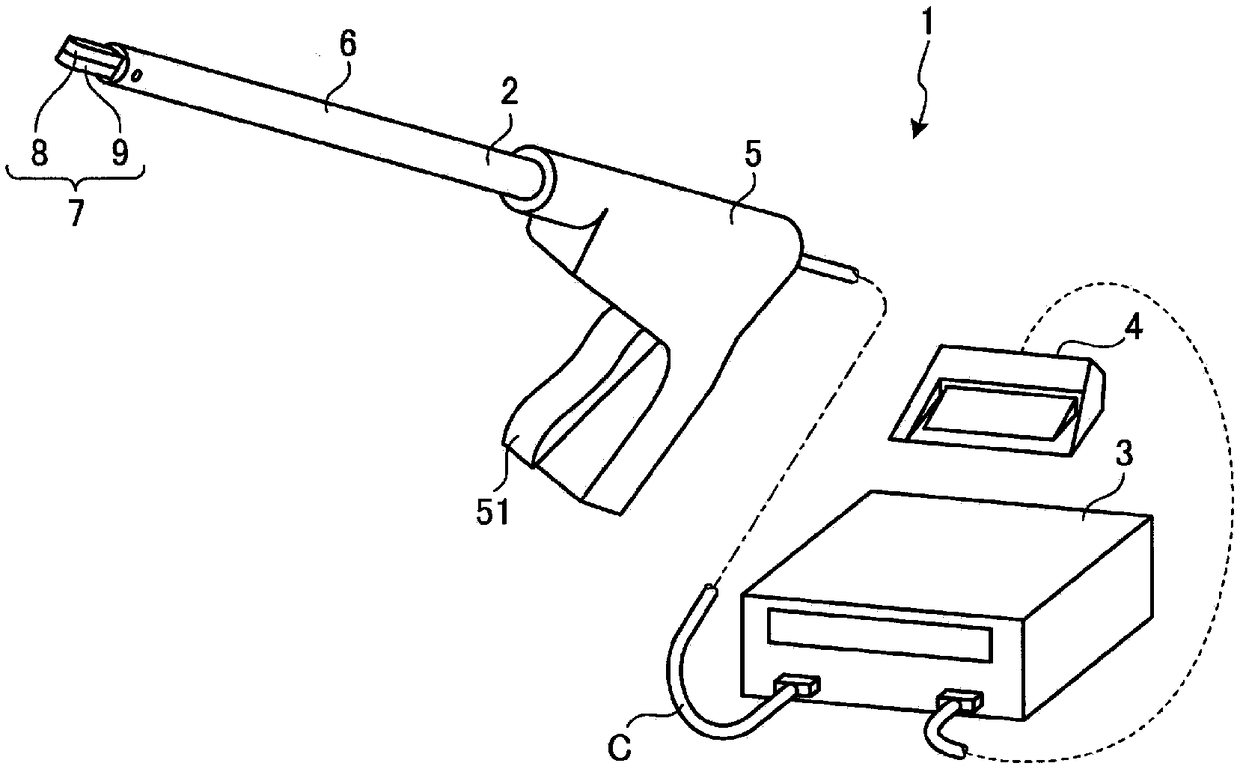

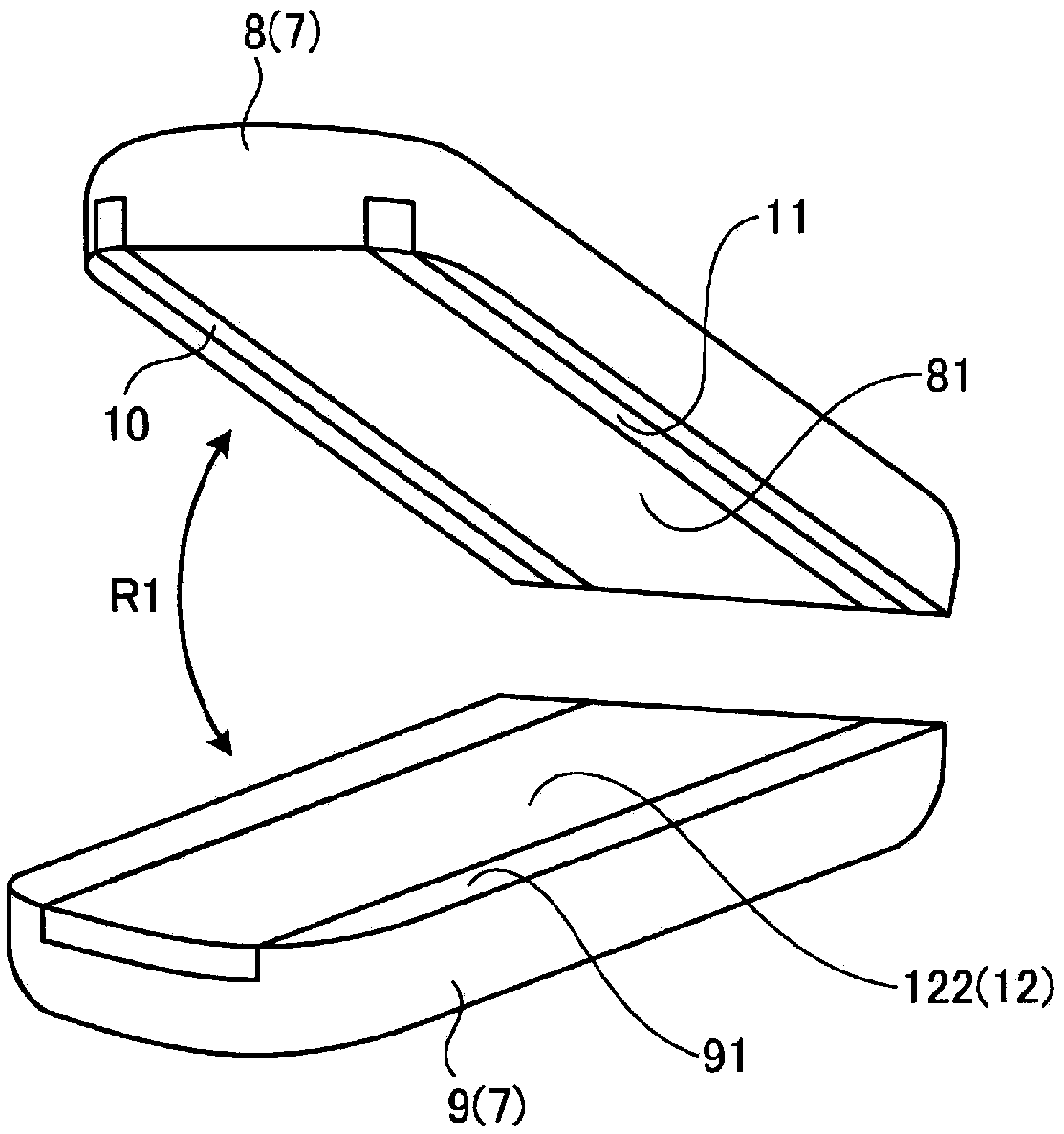

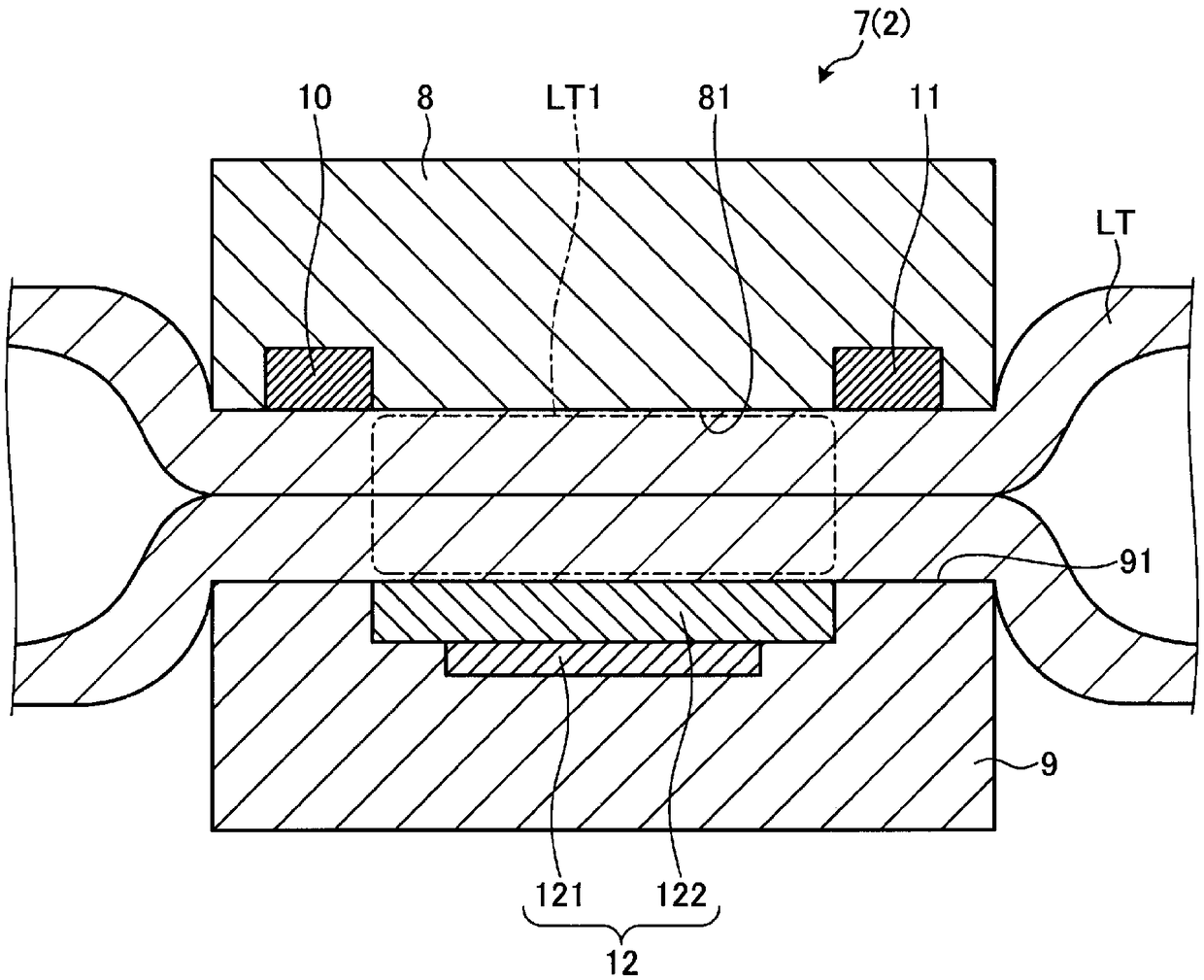

Disposal utensils

ActiveCN109475380BReduce disposal timeDisposal of low traumaSurgical instruments for heatingSurgical forcepsEngineeringLiving body

The treatment instrument comprises: a first jaw (8) with a first gripping surface (81); a second jaw (9) with a second gripping surface (91), which can be positioned on the second gripping surface (91) Grasp the living tissue (LT) between the first grasping surface (81); the first electrode (10) arranged on the first grasping surface (81); the second electrode (11), which is arranged on the first grasping surface (81); A holding surface (81) or a second holding surface (91), capable of supplying high-frequency electric power between the second electrode (11) and the first electrode (10); and a heating element (121) capable of generating heat due to energization, It is provided on at least one of the first jaw (8) and the second jaw (9). Viewed along the direction in which the first gripping surface and the second gripping surface (81), (91) face each other in the state where the first gripping surface and the second gripping surface (81), (91) face each other , the first electrode, the second electrode (10), (11) are respectively disposed at positions where they can sandwich the central position of the heating element (121).

Owner:OLYMPUS CORP

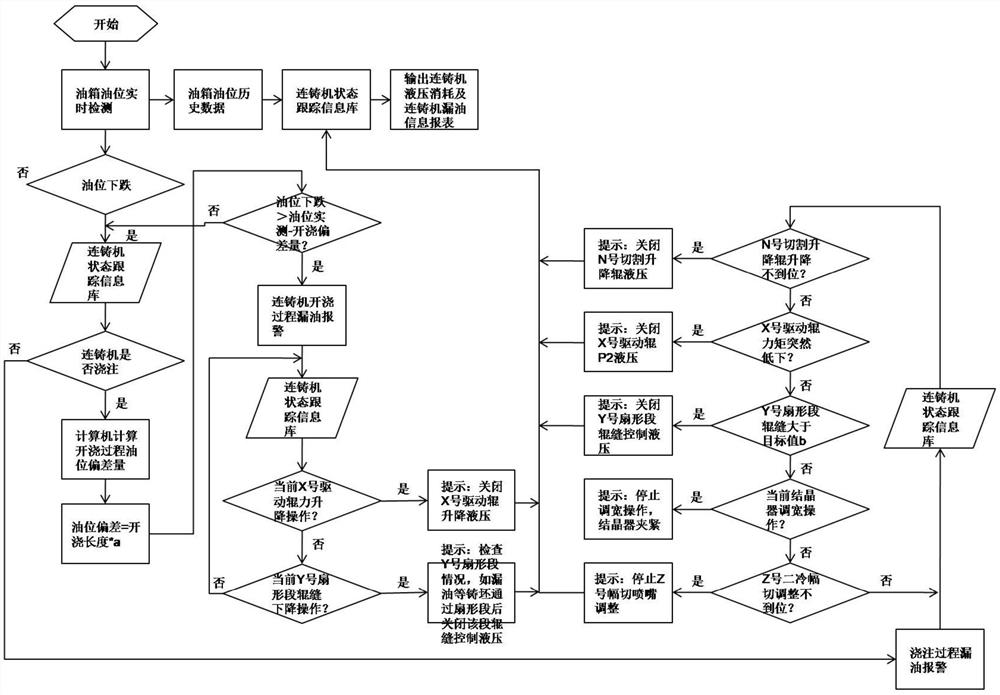

An automatic early warning and judgment method for oil leakage in the hydraulic system of continuous casting machine

ActiveCN111442016BShorten positioning timeReduce disposal timeFluid-pressure actuator safetyControl engineeringMachine

The invention discloses an automatic early warning and judging method for oil leakage in the hydraulic system of a continuous casting machine. According to the application of large data of the continuous casting machine, the time at the same moment is mutually checked, and an alarm is raised and according to the system position, equipment principle and on-site production operation Experience prompts relevant treatment opinions. The invention can quickly analyze and locate the oil leakage at the user point of the hydraulic system of the main engine of the continuous casting machine, and provide an alarm and corresponding emergency plan operation prompt system, so that the field equipment and production operators can quickly determine and deal with the oil leakage according to the prompt of the system points to prevent accidents from expanding.

Owner:BAOSHAN IRON & STEEL CO LTD

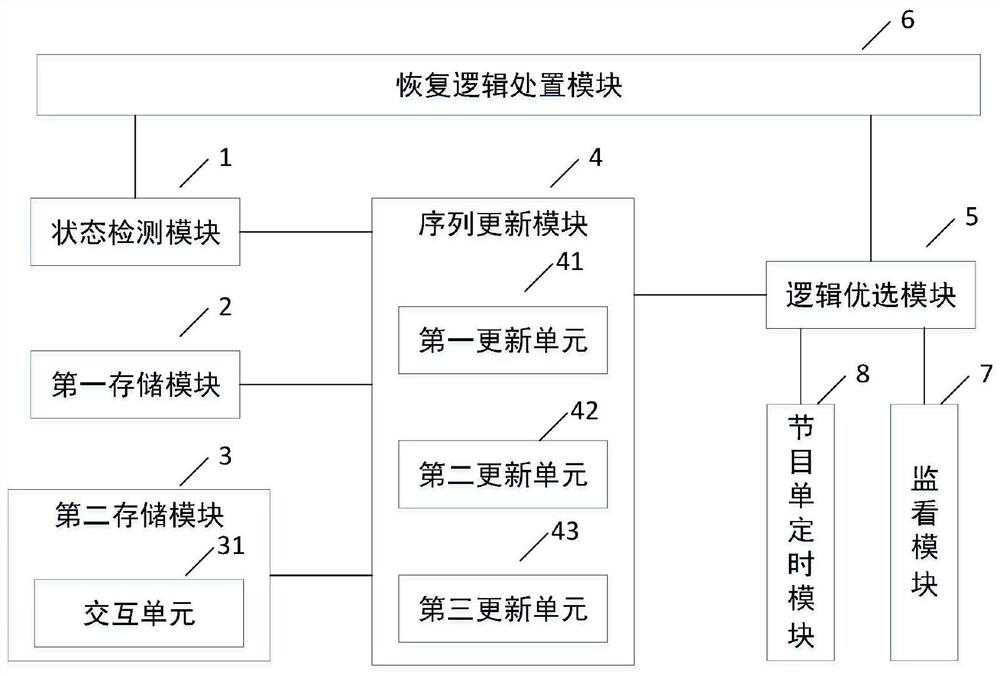

Broadcast logic optimization processing system

ActiveCN112202515ASolve the emergency treatment of personalized broadcastingAccurate emergency responseBroadcast specific applicationsBroadcast information switching/replacementLogic optimizationSignal source

The invention provides a broadcast logic optimization processing system, which relates to the technical field of broadcast emergency processing, and comprises a state detection module used for detecting a real-time state of each signal source, a first storage module used for storing forbidden data of each signal source, a second storage module used for storing a plurality of preset trigger logic blocks which respectively comprise a plurality of trigger conditions and associated condition handling signals, a sequence updating module used for updating the basic priority sequence according to thereal-time state, the forbidden data and the trigger logic blocks to obtain a real-time priority sequence, and a logic optimization module which is used for outputting an emergency disposal signal when a signal state at the broadcast frequency meets a preset emergency disposal condition, and outputting a condition disposal signal when the signal state meets each triggering condition of the triggering logic block. The broadcast logic optimization processing system has the beneficial effects that the emergency signal source is preferably selected in the emergency disposal process, and the judgment and disposal time of technicians is effectively shortened.

Owner:上海文化广播影视集团有限公司 +1

A fast recovery method of satellite-to-ground clock error realized by initial synchronization instruction

ActiveCN111431577BReduce disposal timeReduce waiting timeSatellite radio beaconingRadio transmissionRangingDistance measurement

Owner:BEIJING INST OF SPACECRAFT SYST ENG

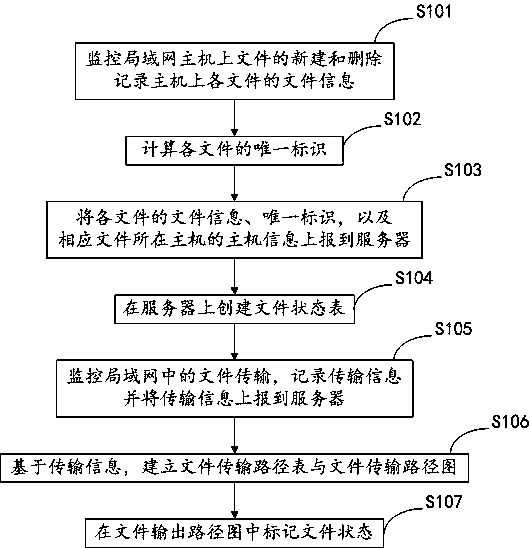

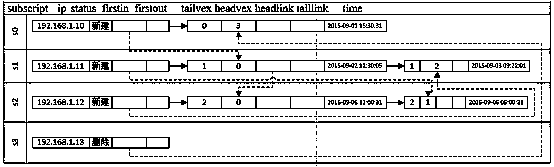

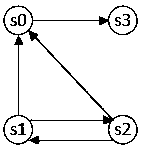

A method and system for recording transmission path and distribution of local area network files

ActiveCN105743732BReduce disposal timeReduce resource usageData switching networksFile system functionsFile transmissionEngineering

The invention provides a method and system for recording transmission paths and distribution conditions of files in a local area network. According to the method and system, host file monitoring is combined with network-level file transmission monitoring, and monitoring data are aggregated to a server for correlation analysis, and therefore, transmission paths and distribution conditions of the files between hosts in the local area network can be generated. With the method and system adopted, the defect of incapability of performing bidirectional monitoring on file transmission, accurately generating transmission paths and analyzing file distribution in the prior art can be eliminated; a basis can be provided for the backtracking of diffusion conditions of analysis files between the hosts, even if the files are deleted, the historical transmission paths of the files can be still recorded; the distribution conditions of virus files between the hosts can be obtained, and a foundation can be provided for virus elimination, and processing time can be effectively reduced.

Owner:HARBIN ANTIY TECH

Manufacturing method of composite medical non-woven fabric absorbent pads

The invention relates to a manufacturing method of composite medical non-woven fabric absorbent pads and belongs to the field of preparation of medical dressing. The manufacturing method includes steps of feeding medical non-toxic polyethylene particles into a screw extruder to fuse and extrude, forming a film through curtain coating, rolling to form anti-adhesive holes, cooling and winding to obtain a medical non-toxic polyethylene film used as an anti-adhesive layer; subjecting blended fibers blended by viscose fibers and high-absorbent fibers to opening by an opener, carding by a carding machine, lapping by a lapping machine and needling by a needle machine, and obtaining non-woven fabric used as a liquid absorbent layer; feeding polyurethane particles into the screw extruder to fuse and extrude, and forming a film by curtain coating, cooling and winding to obtain a polyurethane film used as a waterproof breathable layer; subjecting the anti-adhesive layer and one surface of the liquid absorbent layer to thermal compositing, and subjecting the waterproof breathable layer and the other surface of the liquid absorbent layer to thermal compositing to obtain a composite medical non-woven fabric absorbent pad. The manufacturing method of the composite medical non-woven fabric absorbent pads has the advantages that liquid absorbent quantity is high, leakage to the outside is prevented, contact area of the skin can be remarkably decreased, handling time of medical staff can be shortened, and technical steps are few.

Owner:SUZHOU EMY MEDICAL SUPPLIES

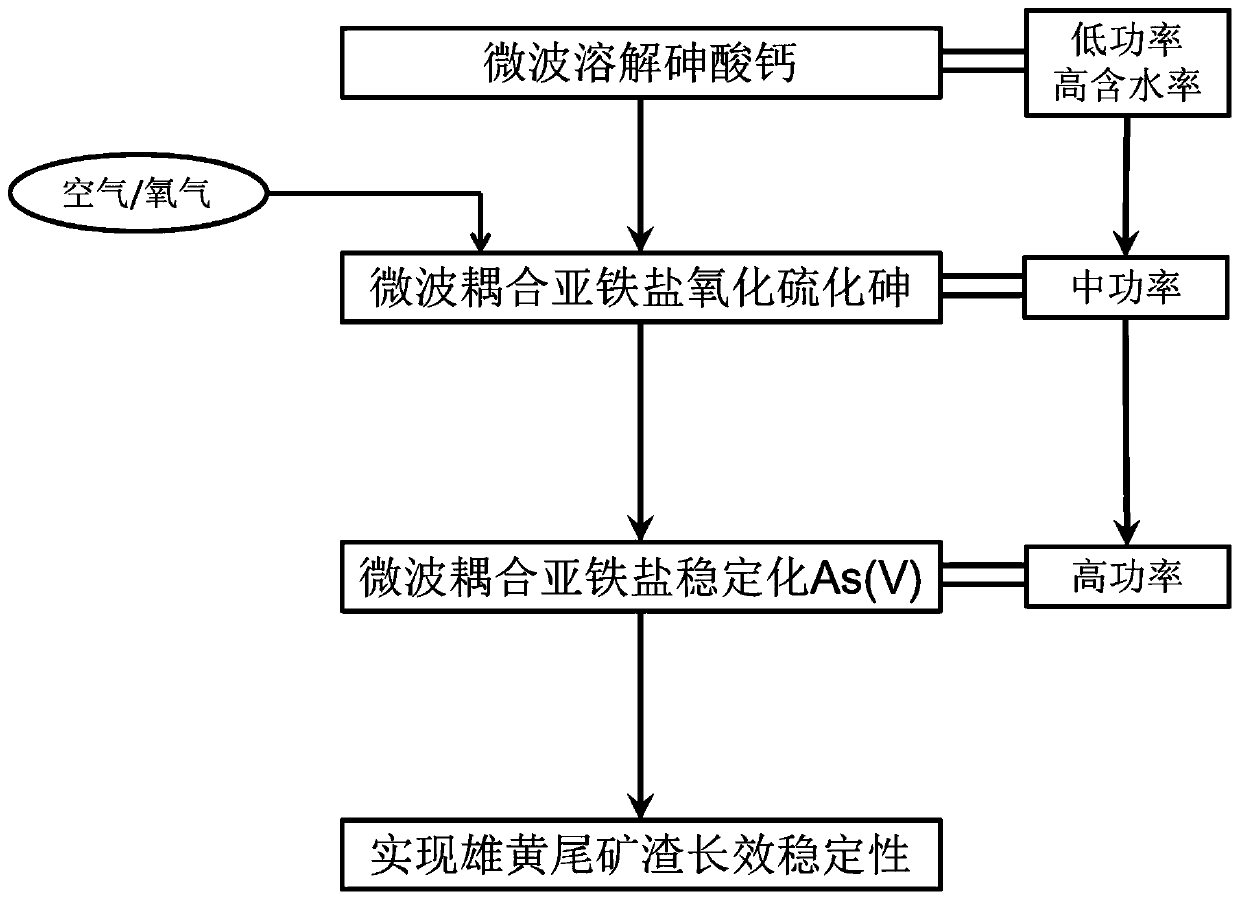

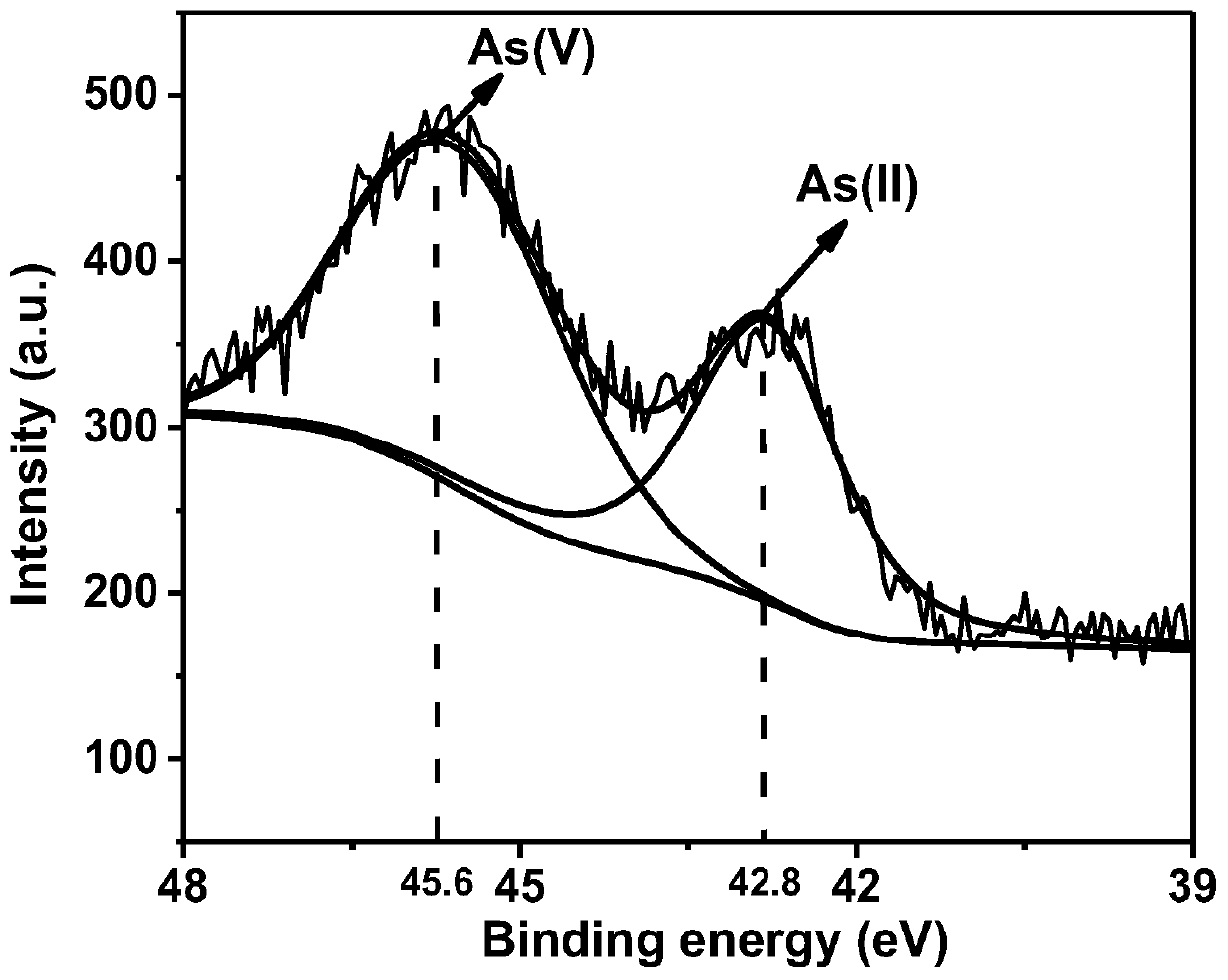

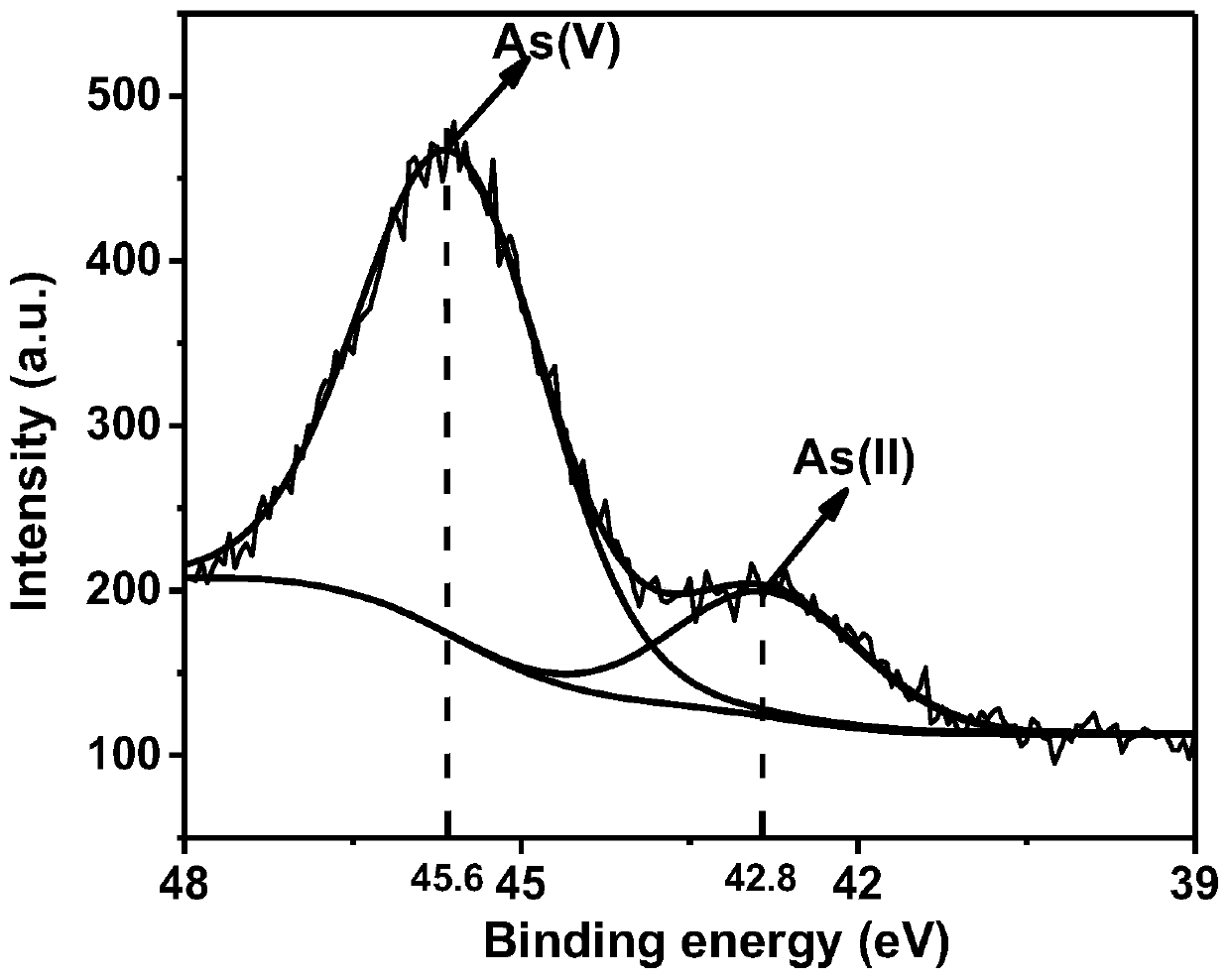

A kind of realgar tailing slag stabilization disposal method

ActiveCN108704239BAchieve dissolutionAchieve stabilizationChemical protectionFerrous saltsPhysical chemistry

The invention discloses a stabilized treatment method for realgar tailing residues. The stabilized treatment method for the realgar tailing residues comprises the following steps of (1) crushing the realgar tailing residues, adding water inside, uniformly stirring, and carrying out first-stage microwave treatment under the action of a microwave field at the power ranging from 100W to 300W; (2) adding water and ferrous salt inside, uniformly stirring, feeding air or oxygen, and meanwhile, carrying out second-stage microwave treatment under the action of a microwave field at the power ranging from 300W to 500W; and (3) carrying out third-stage microwave treatment under the action of a microwave field at the power ranging from 500W to 700W, so that the stabilization of the realgar tailing residues is realized. According to the stabilized treatment method for the realgar tailing residues provided by the invention, through designing a whole process technology of the method, especially improving parameters and conditions of a key microwave treatment process, and dissolving, oxidizing and stabilizing the realgar tailing residues for three stages, the problems of slow calcium arsenate dissolution rate, slow arsenic sulfide oxidation rate and insufficient product long-time stability can be effectively solved.

Owner:HUAZHONG UNIV OF SCI & TECH

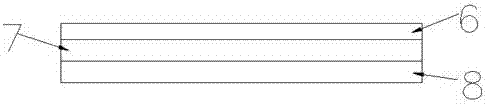

Medicine plaster

InactiveCN107718769AInhibit sheddingReduce usageLayered productsSheet deliveryMedical equipmentBiomedical engineering

The invention relates to a medicine plaster, in particular to a medical disposal plaster which is adhesive with two surfaces, can be used independently and also cooperatively with other medical devices, and belongs to the field of medical supplies. The medicine plaster comprises a substrate with the front and the back, wherein a sticking substance is arranged on the front of the substrate, a protective layer is arranged on the sticking substance and a thin film is arranged on the protective layer, and another sticking substance is also arranged on the back of the substrate and a thin film is also arranged on the sticking substance. The medicine plaster has the characteristics of dual purposes, resource conservation, improved working efficiency and extensive use, adds convenient conditionsfor medical treatment and health and adds a new product for the society.

Owner:张广舜

Treatment tool

ActiveCN109475380AReduce disposal timeDisposal of low traumaSurgical instruments for heatingSurgical forcepsHigh frequency powerMedicine

This treatment tool is provided with: a first jaw (8) having a first holding surface (81); a second jaw (9) having a second holding surface (91) for holding a biotissue (LT) between the first holdingsurface (81) and the second holding surface; a first electrode (10) that is provided to the first holding surface (81); a second electrode (11), which is provided to the first holding surface (81) orthe second holding surface (91), and to which high frequency power is supplied between the first electrode (10) and the second electrode; and a heat generating body (121), which is provided to the first jaw (8) and / or the second jaw (9), and which generates heat when a current is carried thereto. In the state in which the first and second holding surfaces (81, 91) are facing each other, the firstand second electrodes (10, 11) are disposed at positions having the center position of the heat generating body (121) therebetween in the cases where the first and second electrodes are viewed in thefacing direction of the holding surfaces.

Owner:OLYMPUS CORP

Fluidized combustion hot-blast stove coking treatment method

PendingCN112361329AFast and proper processingEliminate failure problemsFluidized bed combustionApparatus for fluidised bed combustionAir volumeThermodynamics

The invention discloses a fluidized combustion hot-blast stove coking treatment method. When the combustion temperature of a dense-phase zone is monitored and the temperature change speed is too high,the coal feeding amount should be reduced, and the air volume should be correspondingly increased; when the temperature rise can not be effectively controlled by the measures, a slag discharging pipeclose to a coal feeder side is immediately subjected to slag discharging, and slag discharging is stopped when the temperature has a decreasing trend; if the particle size is too large to boil, the cold slag discharge can be enhanced, and the air supply can be properly increased in a short time; when small coke blocks are coked in a stove, an operator needs to dredge a slag pipe in time, observesthe deslagging condition of the pipe is observed within a considerable period of time, and more slag is discharged than other deslagging pipes during deslagging until the small coke blocks are completely discharged; and if coking is serious, the stove is stopped, slag blocks in a hearth are cleaned away, cold slag is paved for re-ignition, and a cold state test is performed before ignition to check the air distribution uniformity of a hood. The treatment method is quick and appropriate, faults can be eliminated in time, the treatment time is greatly shortened, and the working efficiency of equipment is improved.

Owner:安徽禹王加热炉制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com