Explosion-proof method for milling high-volatile coal by coal mill

A high-volatile, coal mill technology, applied in the field of coal mills, can solve the problems of coal mill powder accumulation, abnormal pulverization system, and reduction of coal mill output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

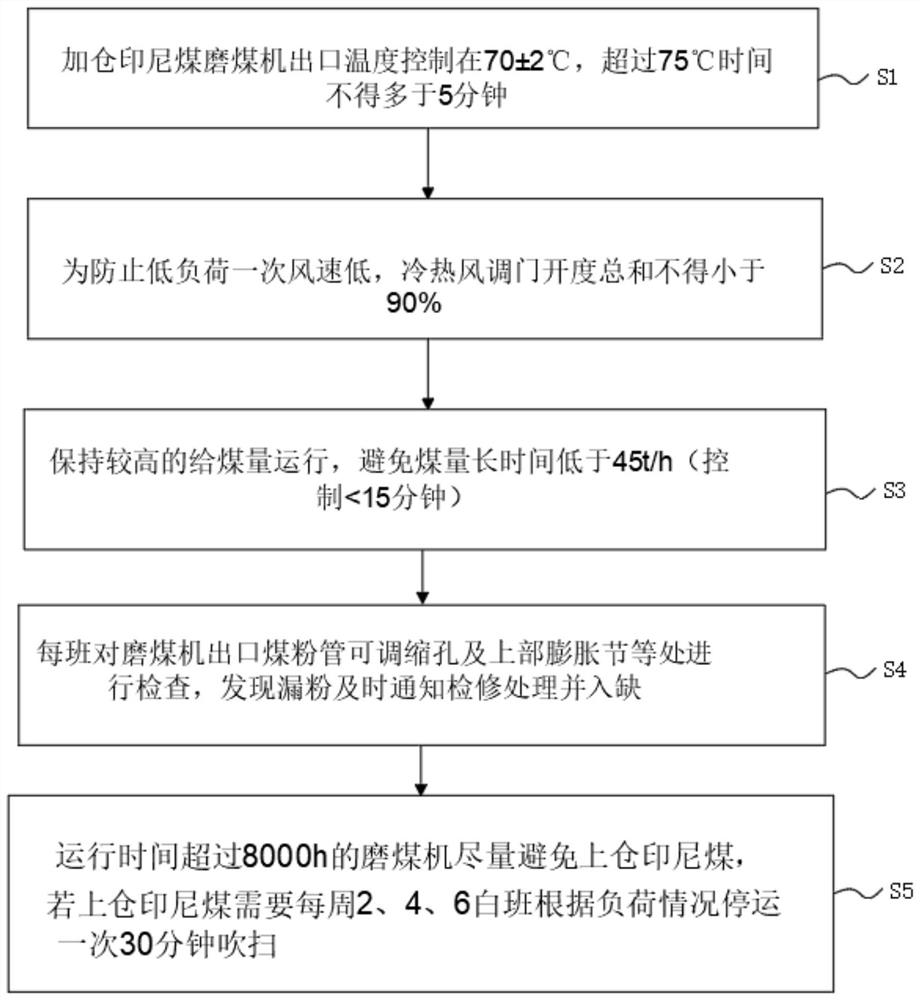

[0026] Please refer to figure 1 and figure 2 ,in, figure 1 A flow chart of a preferred embodiment of the explosion-proof method for grinding high-volatile coals with a coal mill provided by the present invention, figure 2 The accompanying drawing of the temperature measuring table is a preferred embodiment of the explosion-proof method for grinding high volatile coals by the coal mill provided by the present invention. The explosion-proof method for grinding high volatile coal types by coal pulverizers includes the following steps:

[0027] S1. The outlet temperature of Jiacang Indonesian coal pulverizer is controlled at 70±2°C, and the time exceeding 75°C shall not exceed 5 minutes;

[0028] S2. In order to prevent low primary wind speed under low load, the sum of the openings of the hot and cold air dampers shall not be less than 90%;

[0029] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com