Self-adaptive ignition wall-hanging stove and control method thereof

A technology of self-adaptive ignition and control method, applied in the field of wall-hung boilers, can solve the problems of reducing user experience, affecting ignition efficiency, and high ignition success rate, so as to improve ignition adaptability, user experience and service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

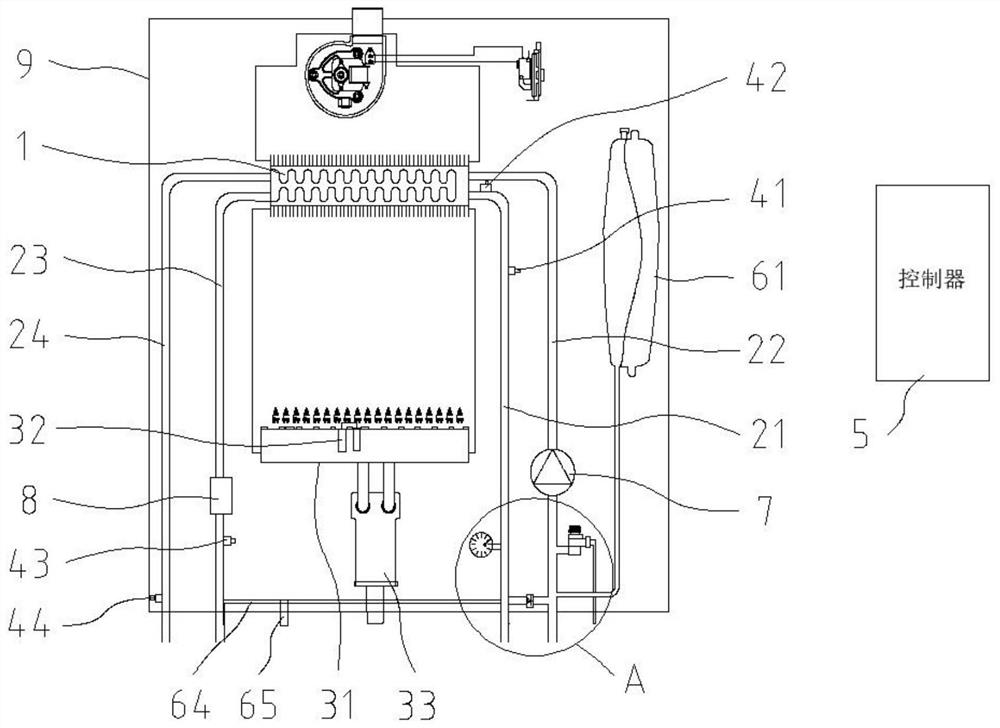

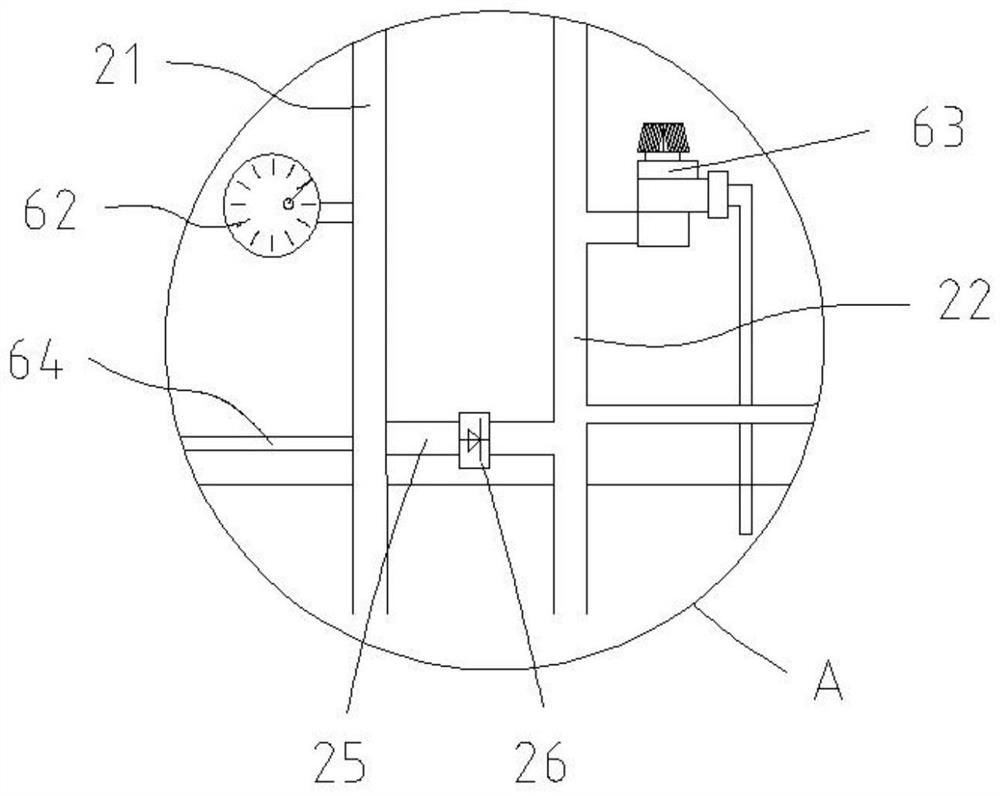

[0027] see Figure 1-2 , this embodiment provides an adaptive ignition wall-hung boiler, including a wall-hung boiler body 9, a heat exchanger 1, a heating pipeline (not shown in the figure), a bathing pipeline (not shown in the figure), a burner 31. Ignition device 32, gas control valve 33, heating temperature measuring device 41, water pump 7 and controller 5, wherein the heat exchanger 1 is set in the wall-hung boiler body 9, which has a heating water outlet, a heating return water inlet, a bath inlet A water outlet and a water outlet for bathing (not shown in the figure). The heating pipeline includes a heating water outlet pipe 21 and a heating return water pipe 22. The two ends of each connect to the outlet of the radiator of the wall-hung boiler and the heating return port of the heat exchanger 1 respectively. The bathing pipeline includes a bathing water inlet pipe 23 and a bathing water outlet pipe 24. The two ends of the bathing water inlet pipe 23 are respectively...

Embodiment 2

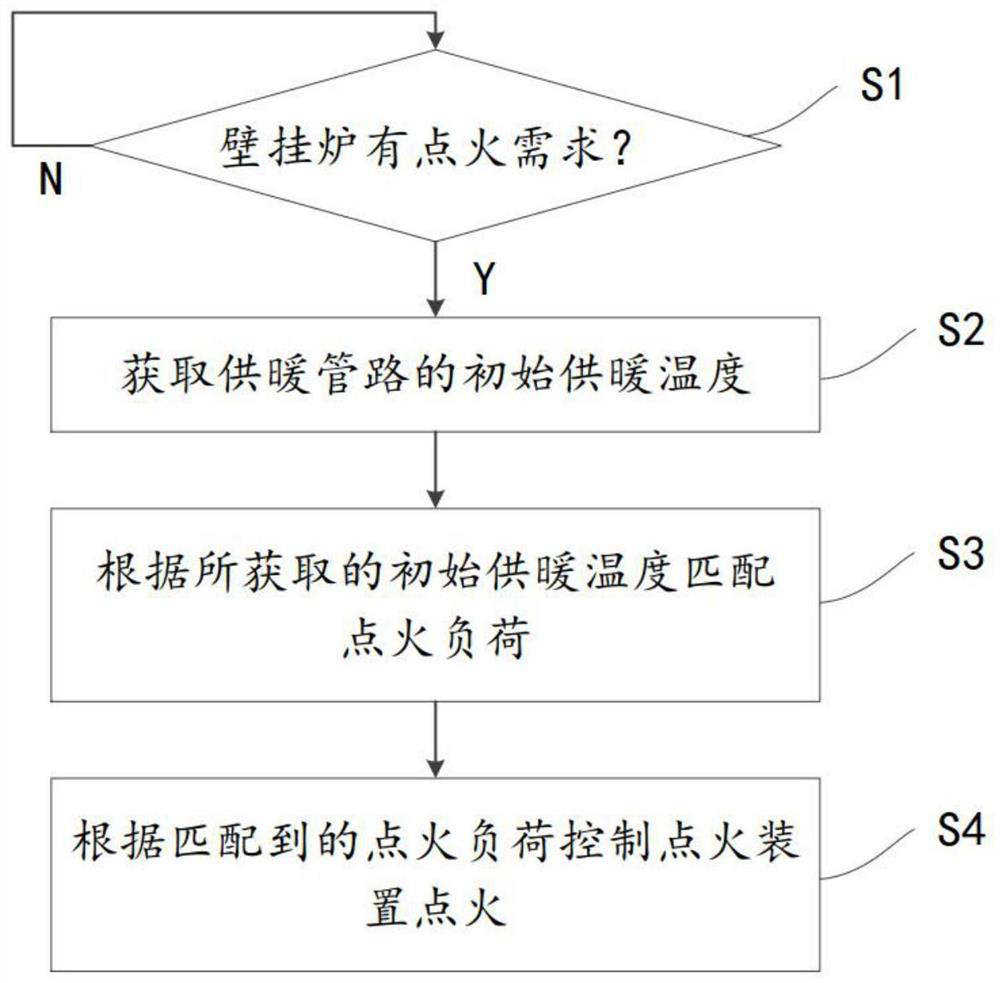

[0040] see image 3 , this embodiment provides a control method for a wall-hung boiler, which uses an adaptive ignition wall-hung boiler as described in Embodiment 1, and the control method includes the following steps:

[0041] S1: Continue to judge whether there is an ignition demand for the wall-hung boiler, and if so, go to the next step;

[0042] Specifically, the continuous determination of whether the wall-hung boiler has an ignition demand specifically includes two schemes: the first scheme, when the user has a bathing demand, whether the bathing water flow detected by the controller 5 through the water flow detection device 8 reaches the wall-hung boiler. If the furnace start-up flow is reached, it indicates that the wall-hung boiler has an ignition demand and enters step S2. If it is not reached, it indicates that the wall-hung boiler has no ignition demand for the time being. 41 Whether the detected heating outlet water temperature is lower than the threshold of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com