Fully automatic abrasive cut-off machine

A grinding and cutting machine, fully automatic technology, applied in the direction of grinding machines, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of poor processing accuracy, health injuries of operators, and large labor workload, and achieve good environmental protection effects and high The effect of productivity and machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

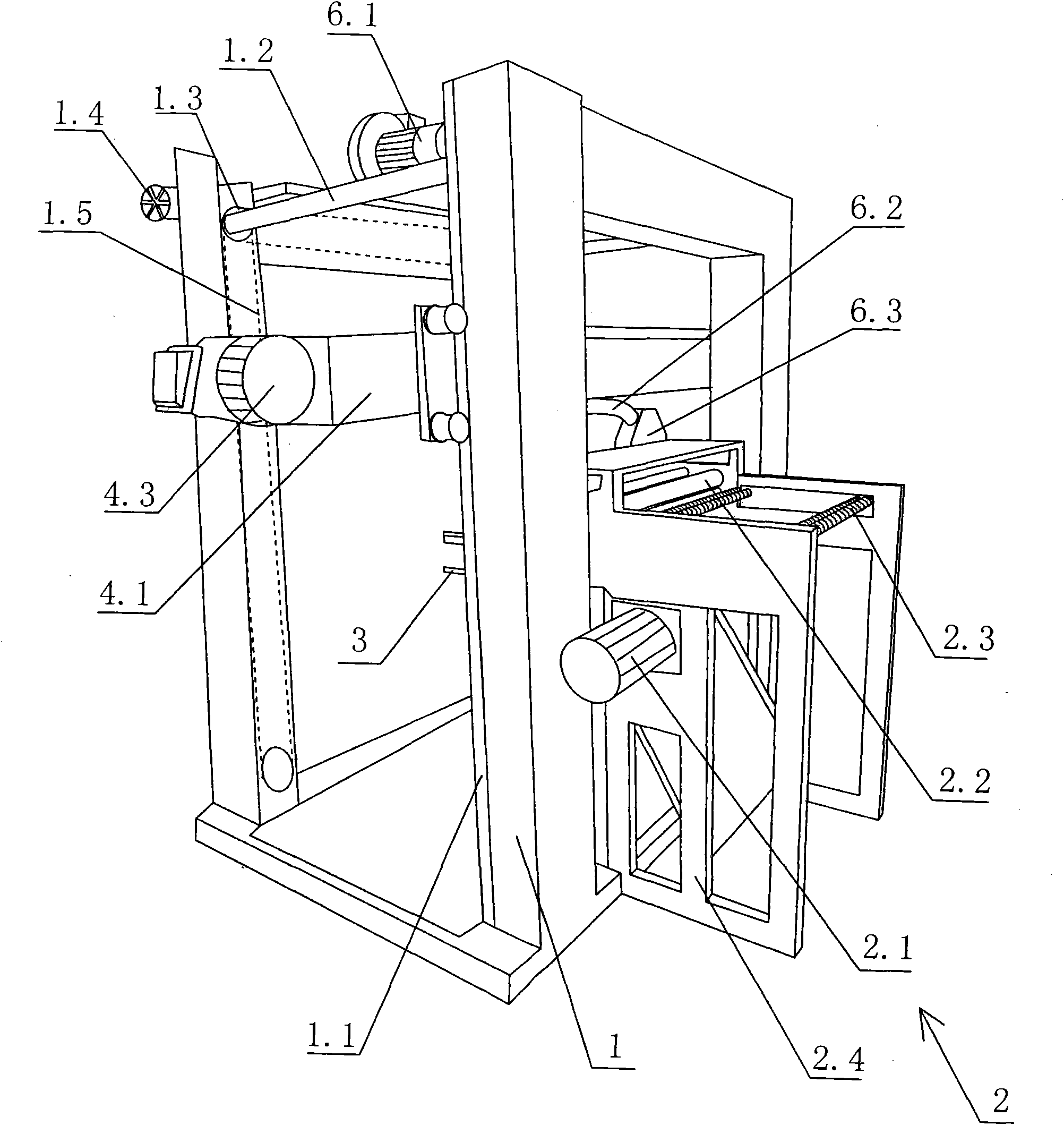

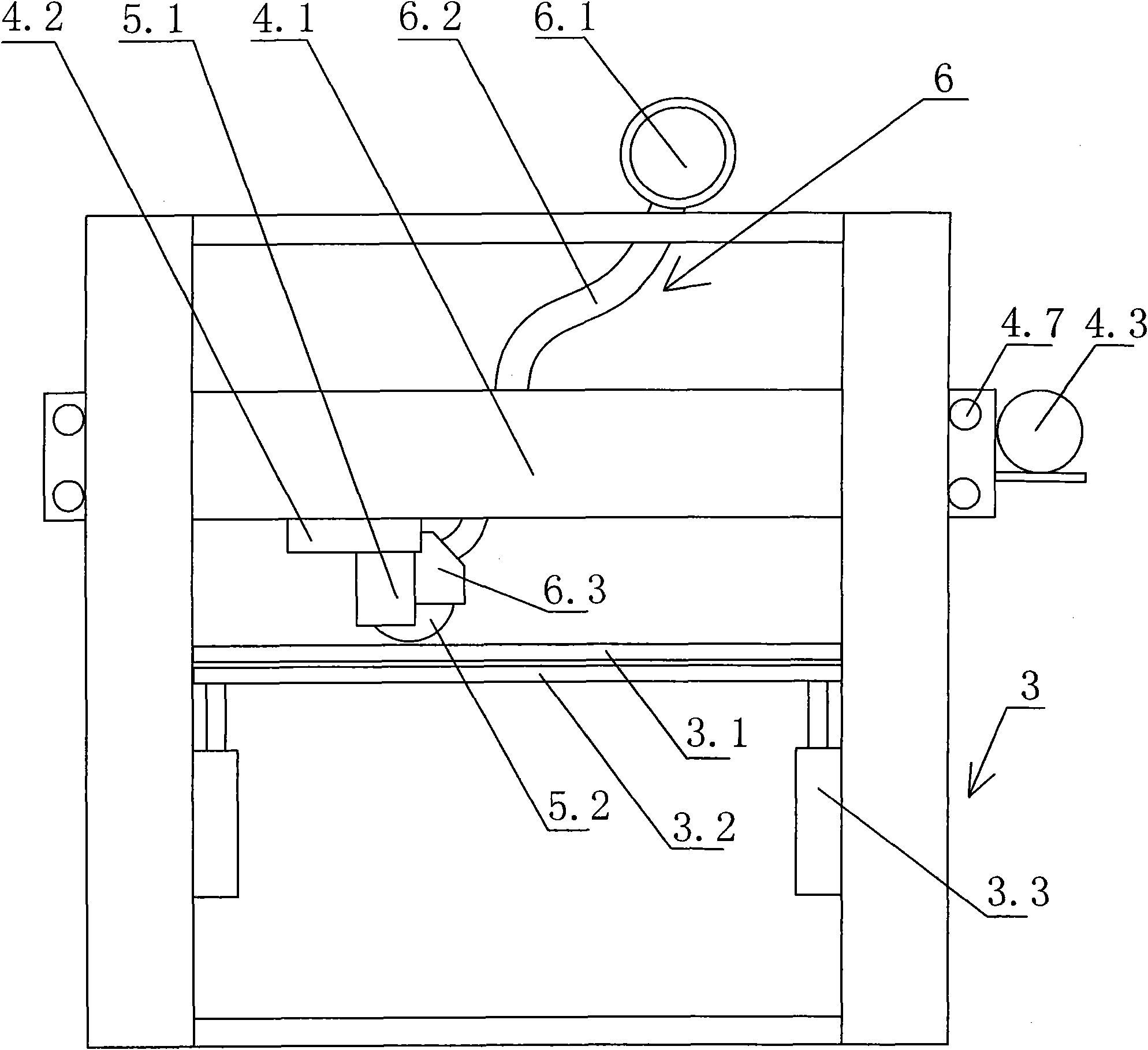

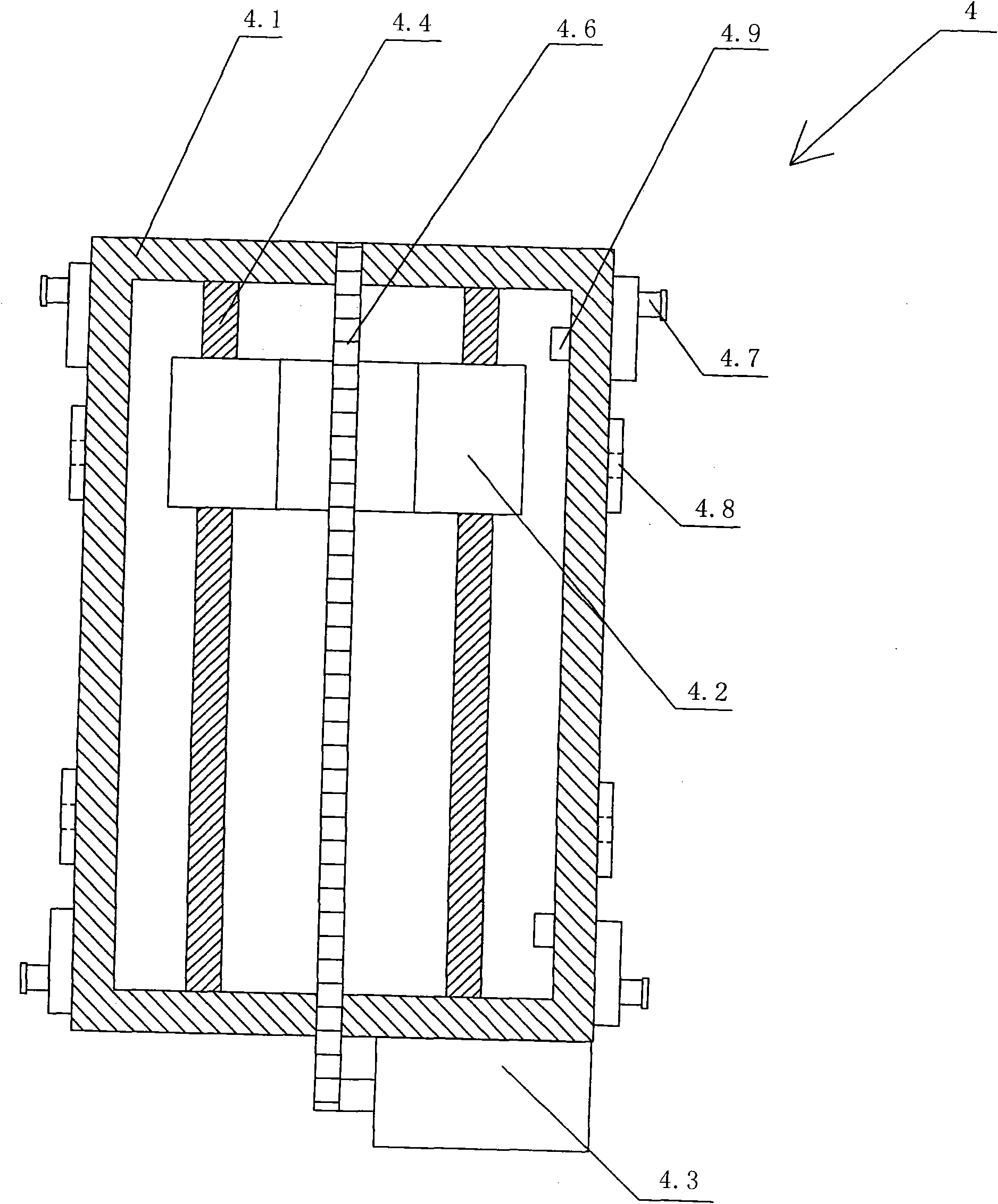

[0034] see figure 1 with figure 2 , the present invention relates to a fully automatic grinding and cutting machine, comprising a frame 1, a feeding mechanism 2, a clamping mechanism 3, a translation lifting mechanism 4, a grinding mechanism 5 and a dust suction mechanism 6, the four Guide rails 1.1 are provided on the outer side of the pillars, and lifting sprockets 1.3 are installed on the inside of the above-mentioned pillars. The lifting sprockets 1.3 located on the upper part of the pillars are connected by transmission rollers 1.2, and the lifting sprockets 1.3 are connected by lifting chains 1.5. Transmission, the transmission roller 1.2 is connected with the dial wheel 1.4 arranged on the side of the frame 1, the feeding mechanism 2 includes a stepping motor 2.1, a rubber roller 2.2, a feeding screw 2.3 and a feeding rack 2.4, and the feeding screw 2.3 and the rubber roller 2.2 are erected on the feeding frame 2.4 in sequence, and the rubber roller 2.2 is symmetrical...

Embodiment 2

[0040] see Figure 5 The difference between the second embodiment and the first embodiment is that the grinding and cutting machine also includes a conveying mechanism 7, the conveying mechanism 7 is arranged below the clamping mechanism 3, and the conveying mechanism 7 is composed of rollers mounted on both ends of the bracket. And the conveyor belt wrapped around the roller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com