Uniset direct seeding machine and on-film hole-leveling direct seeding machine containing same

A live broadcast machine and single technology, which is applied in the direction of intermittent quantitative seeding machinery, agricultural gas emission reduction, fertilizer and sowing equipment, etc. And efficiency, maintenance, maintenance inconvenience and other issues, to achieve high promotion and application value, improve planting efficiency, save labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

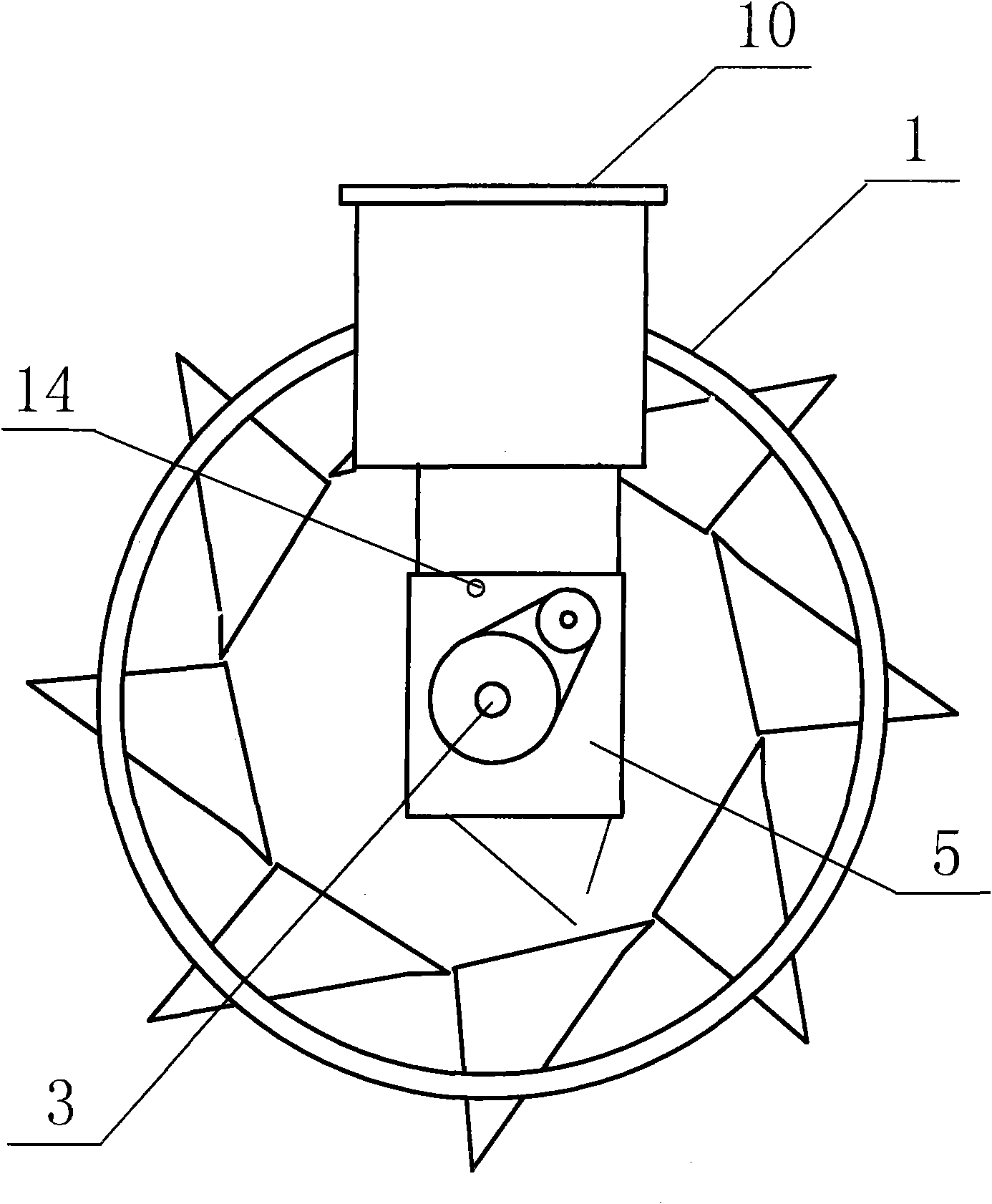

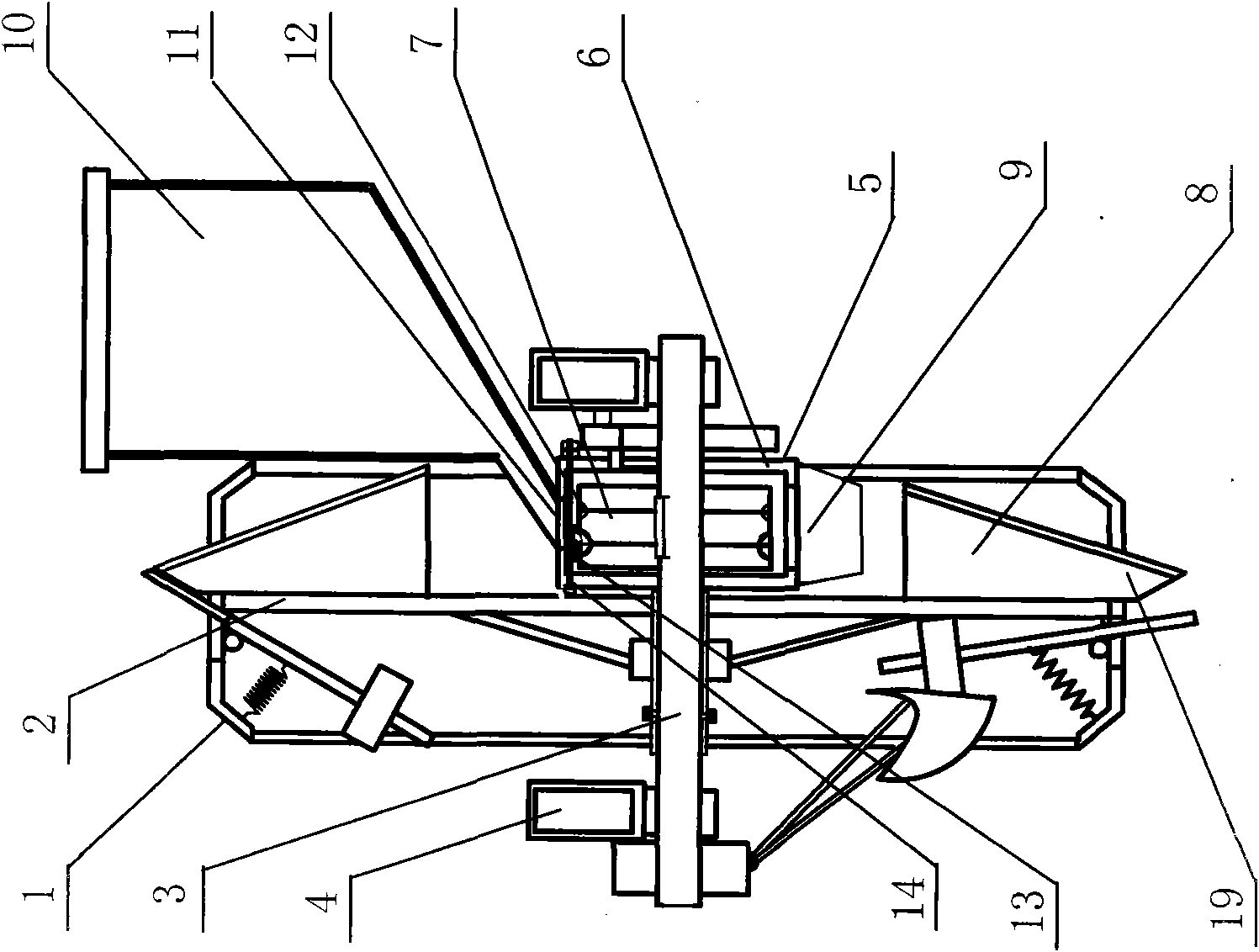

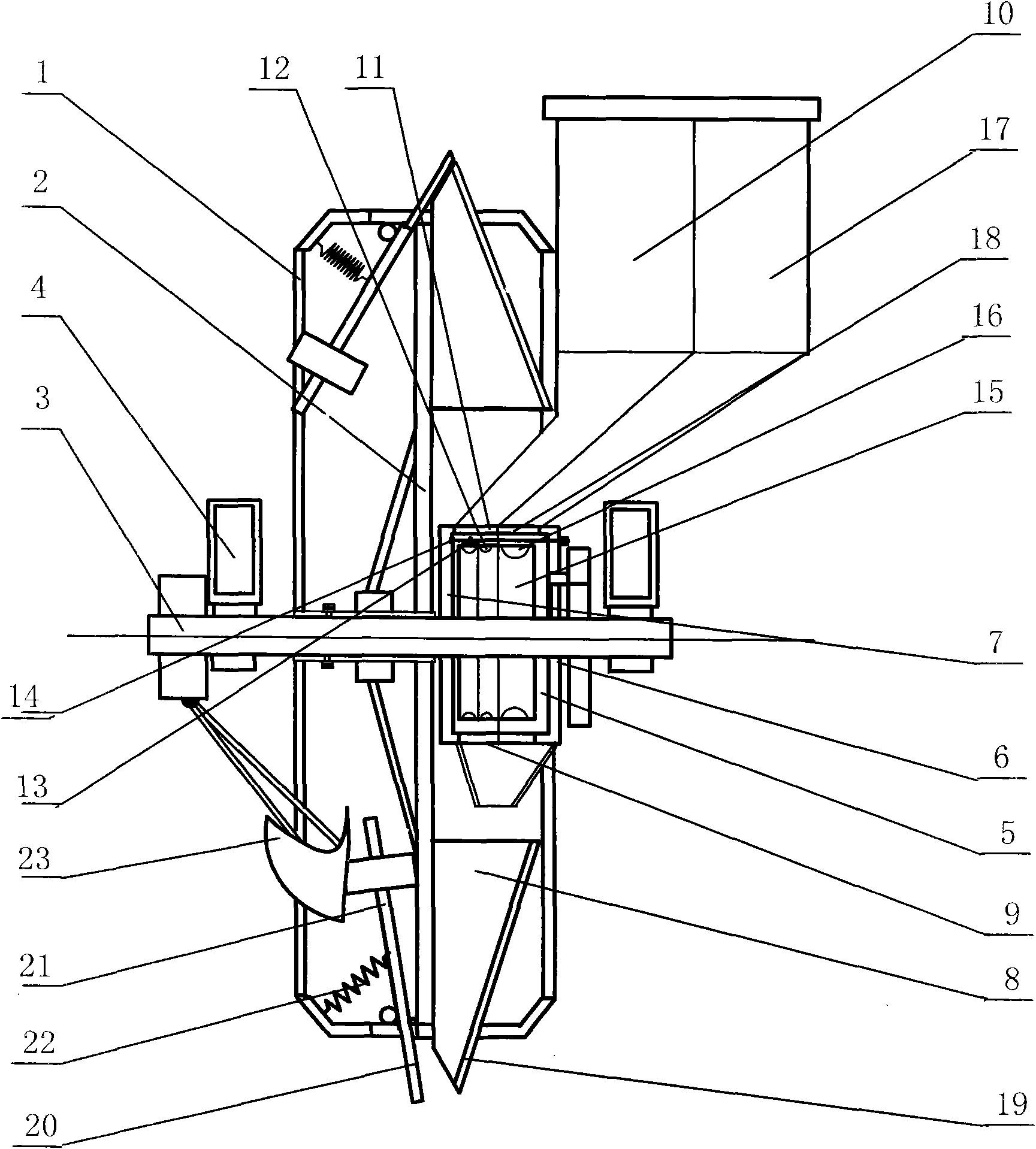

[0025] Such as figure 1 , figure 2 As shown, the main structure of the single live broadcast machine is a rotating roller. The rotating part includes a drum 1 and a wheel 2 fixed on its inner wall. The middle part of the rotating shaft 3 is fixed on the wheel 2. Above; the wheel disc 2 divides the space inside the drum 1 into two areas, the left and the right, with the outer end open. It is equipped with a seed quantitative distribution mechanism and a seed delivery mechanism; the quantitative seed metering device 5 is set upright in the middle of the sowing area, and its housing 6 is fixed on the suspension frame 4, and the seed distribution wheel 7 inside is fixed on the rotating shaft 3. The wheel disk 2 around the quantitative seed metering device 5 is provided with an annularly connected seed distribution funnel 8, the bottom opening of the feeding funnel 9 at the bottom of the quantitative seed metering device 5 is opposite to the opening front of the seed distribution...

example 2

[0028] Such as image 3 Shown, the fertilizer distribution wheel 15 that is arranged side by side with the seed distribution wheel 7 is also provided with in this quantitative seed metering device 5, is provided with the fertilizer groove 16 corresponding with seed groove 12 on the fertilizer distribution wheel 15, fertilizer Case 17 is fixed on the hitch frame 4, and its bottom chute is connected with the mouth fertilizer inlet 18 on the quantitative seed metering device 5 . The rest are the same as example 1.

example 3

[0030] Such as Figure 4 Shown, the suspension device that is made of damping spring 32 and damping rod is housed on the hitch 4 of single live broadcast machine. The rest are the same as example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com