Cutting device for the tobacco industry and method for disabling the cutting device

A cutting equipment, tobacco technology, applied in the direction of tobacco, application, manufacturing of cigarettes, etc., can solve problems such as collision danger, and achieve the effect of large collision protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

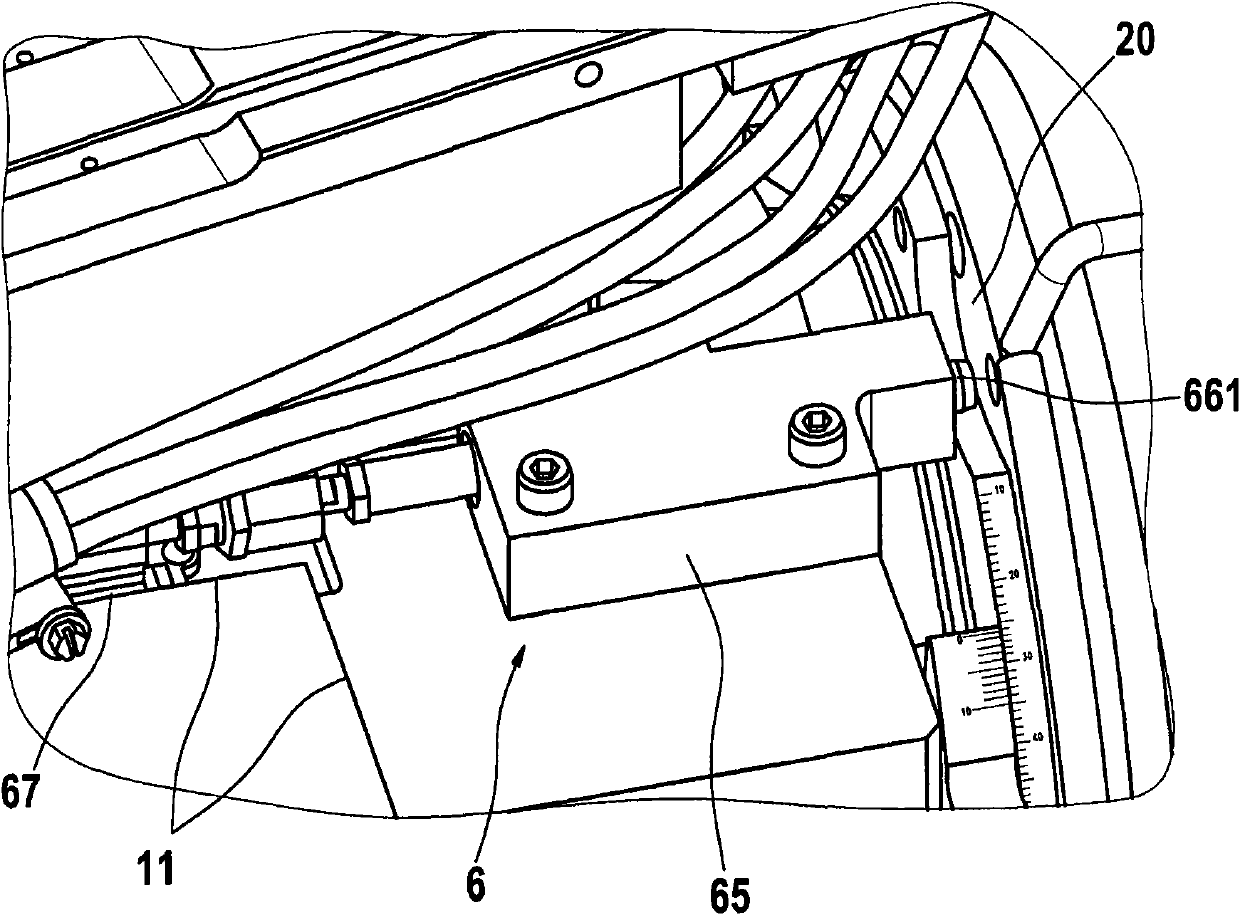

[0026] The cutting device according to the invention is designed as a machine in the tobacco processing industry for cutting at least one conveyed strand into a plurality of rod-shaped products. In particular, cigarettes are processed from tobacco sticks, ie from double-length sections cut from tobacco bundle rods 9, 9'. The tobacco bundle 9 or 9' is fed continuously and at a constant speed in the conveying direction F. The cigarette sticks 91 or 91' (not shown) are cut (abtrennen) by the cutting device 1 and delivered to an intermediate conveyor (ie a so-called star wheel not shown). Such a spider is known, for example, from DE 10 2004 013 972 A1. Filters are also cut, for example, at the point of the cigarette.

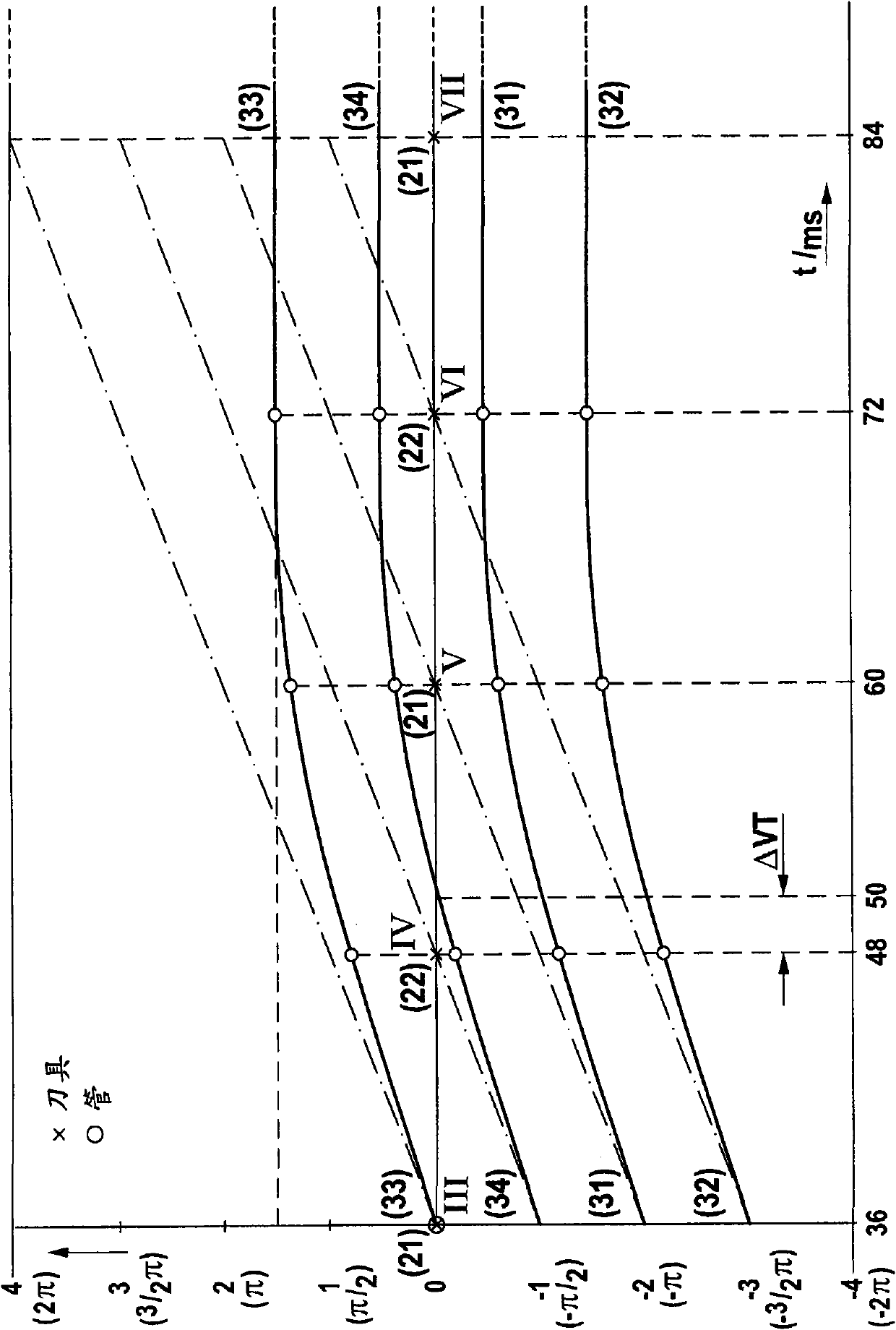

[0027] The cutting device 1 is designed in a special manner according to the invention. With the cutting device 1 described in the exemplary embodiment, specific method steps according to the invention can be carried out for shutting down the cutting device—in pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com