Method for lubricating pulp dewatering thickener

A concentrator and slurry technology, applied in separation methods, chemical instruments and methods, precipitation separation, etc., can solve problems such as wear, waste of manpower and material resources, waste of mechanical parts, etc., achieve simple electrical wiring, improve production efficiency, and ensure continuity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

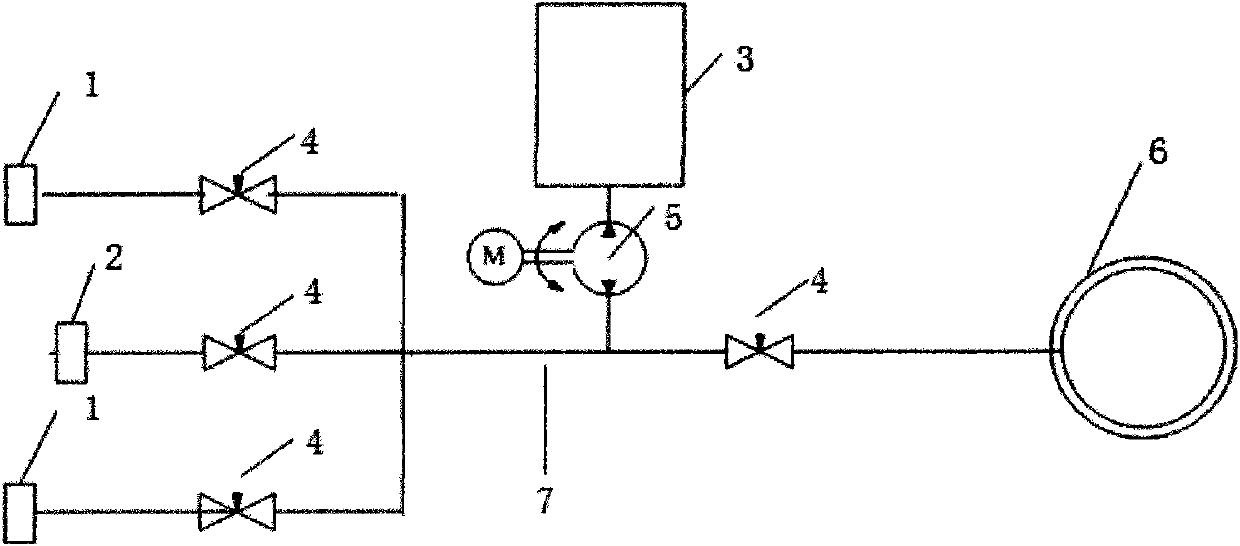

[0016] like figure 1 As shown, the thickener is connected with a lubricating grease conveying pipeline 7, and the pipeline adopts a seamless steel pipe with a diameter of 10mm, and the fixed position is installed on the thickener beam frame. The lubricating grease delivery pipeline 7 can transport the lubricating grease to the central end face bearing 6 , the traveling roller 1 and the traveling sprocket 2 of the thickener. A regulating valve 4 is provided on the lubricating grease conveying pipeline, and the regulating valve can regulate and control the replenishment amount of grease. The grease inlet of the lubricating grease delivery pipeline is connected with the electric grease replenishing pump 5, and the grease inlet of the electric grease replenishing pump is connected with the lubricating grease barrel 3.

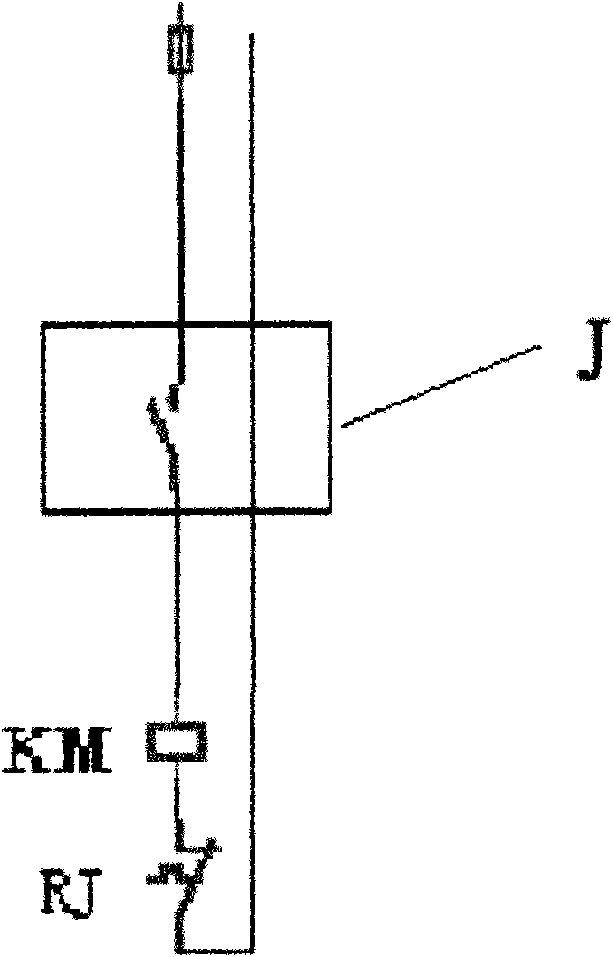

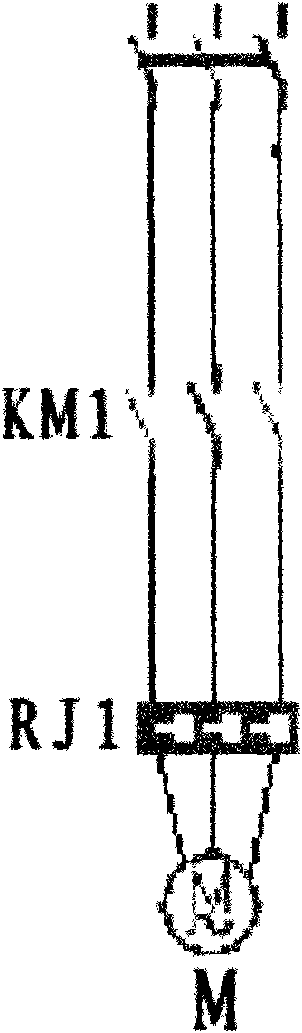

[0017] The working power of the electric grease supplement pump 5 can be supplied from the air switch of the power supply of the electric control cabinet of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com