Aqueous gloss oil for beer cartons and preparation method thereof

A water-based varnish and carton technology, which is applied in papermaking, paper coating, textiles and papermaking, etc. It can solve the problems of damaging the printing effect of the carton surface, difficult to achieve the performance of water-based varnish, and carton adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Water-based varnish formula 1

[0022] Modified styrene-acrylate emulsion 80%;

[0023] Silane defoamer 0.1%;

[0024] Styrene-acrylate emulsion 10%;

[0025] Modified polyethylene wax 4%;

[0026] Water-based chloromethyl / methylisothiazolinone (CMI / MI) mixture preservative 0.1%;

[0027] Isopropanol 5.8%.

[0028] The sum of the mass percentages of the above raw materials is equal to 100%.

[0029] (2) Preparation method

[0030] At room temperature, first add the modified styrene-acrylate emulsion, then slowly add silane defoamer, styrene-acrylate emulsion, modified polyethylene Wax, water-based chloromethyl / methylisothiazolinone (CMI / MI) blend preservative, isopropyl alcohol. After adding various raw materials, stir for ten minutes under the state of rotating speed of 500-1000 rpm, so that various materials in the system are evenly dispersed, and a water-based varnish for beer cartons is obtained.

Embodiment 2

[0032] (1), water-based varnish formula 2

[0033] Modified styrene-acrylate emulsion 70%;

[0034] Silane defoamer 0.1%;

[0035] Styrene-acrylate emulsion 20%;

[0036] Modified polyethylene wax 5%;

[0037] Water-based chloromethyl / methylisothiazolinone (CMI / MI) mixture preservative 0.1%;

[0038] Isopropanol 4.8%.

[0039] The sum of the mass percentages of the above raw materials is equal to 100%.

[0040] (2) The preparation method is the same as in Example 1, so details are not repeated.

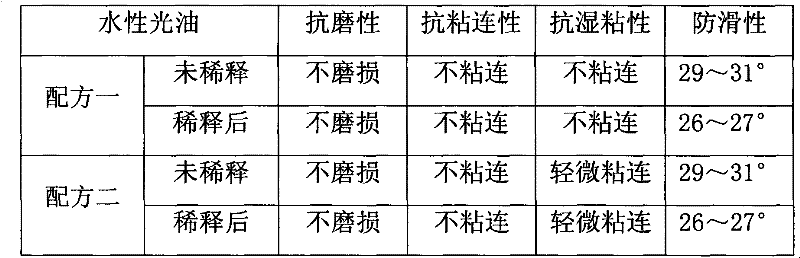

[0041] Application Implementation Notes

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com