Manufacture method of plastic faucet body

A manufacturing method and faucet technology, applied to the valve details, engine components, valve housing structure, etc., can solve the problems of user troubles, reduce production efficiency, single shape of the water outlet pipe, etc., achieve the effect of convenient processing and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0027] The manufacturing method of the plastic faucet body of the present invention comprises the following steps:

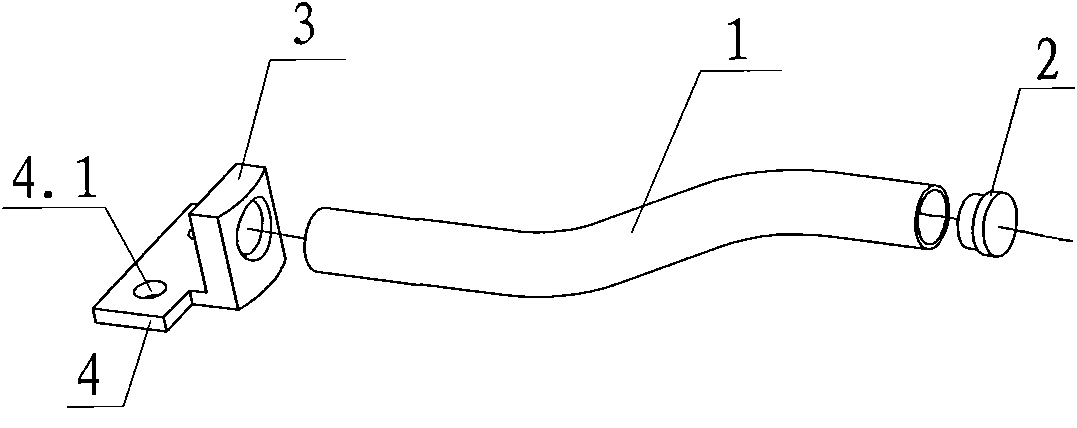

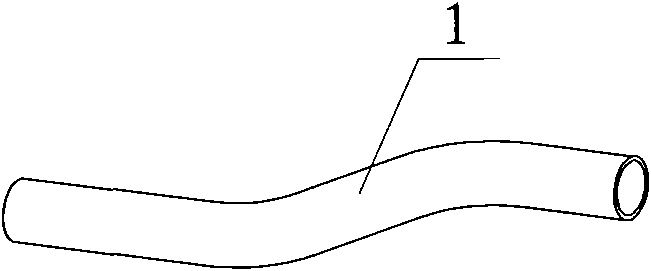

[0028] ①, such as figure 1 As shown, according to the shape of the outlet pipe 8 of the plastic faucet to be made, the metal insert 1 with a channel matching it is processed, and the metal insert 1 can be stamped and formed. In this specific embodiment, the described The metal insert 1 is an insert made of stainless steel.

[0029] ②, such as figure 2 As shown, the first plug 2 and the second plug 3 are plugged on both ends of the metal insert 1 to seal the pipeline in the metal insert 1, so that the material will not flow into the pipeline of the metal insert 1 during injection molding Inside.

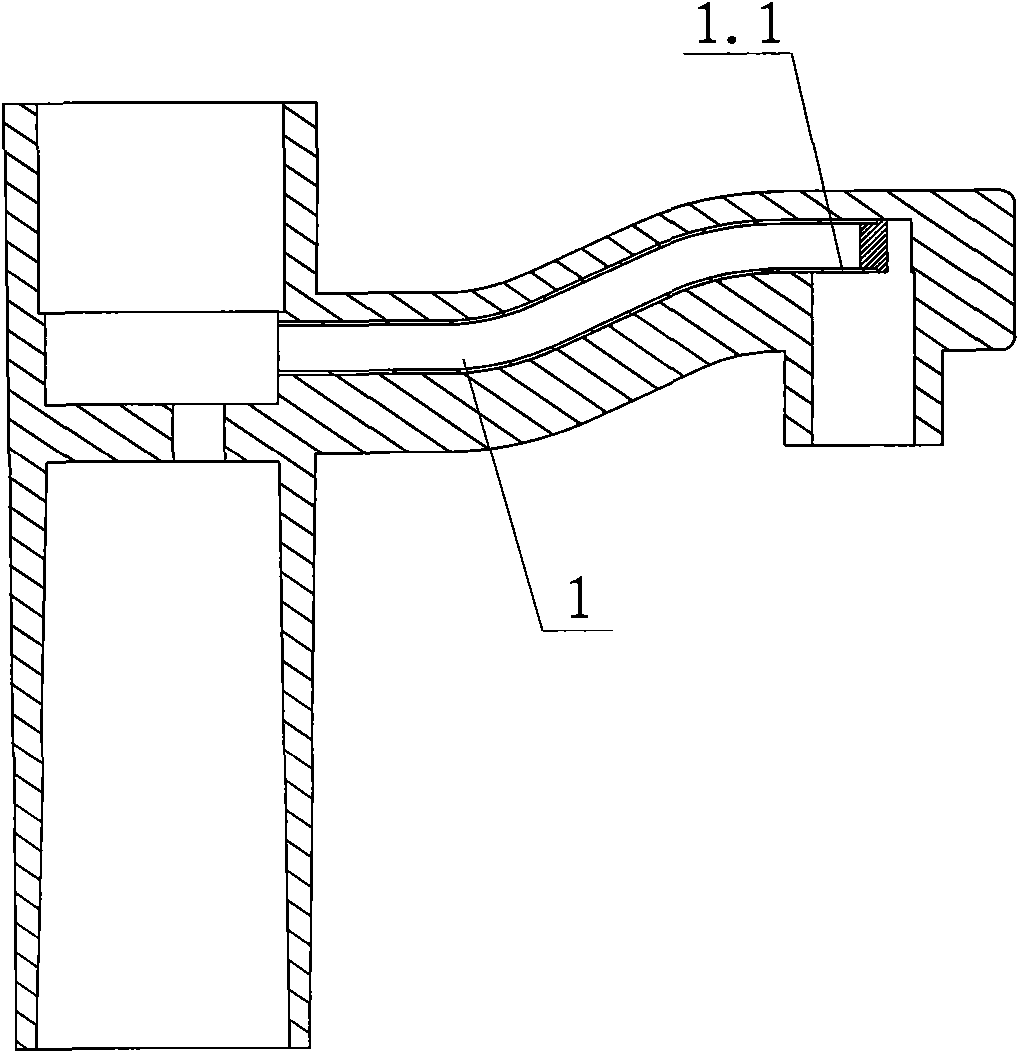

[0030] ③, such as image 3 As shown, the metal insert 1 plugged with plugs at both ends is positioned in the mold cavity 5.3 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com