Methane devulcanizer quick joint convenient to assemble and disassemble

A biogas desulfurization and desulfurizer technology, applied in the direction of couplings, mechanical equipment, etc., can solve the problems that the desulfurizer cannot function, the gas pipeline becomes hard, and the interface is difficult to seal reliably.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

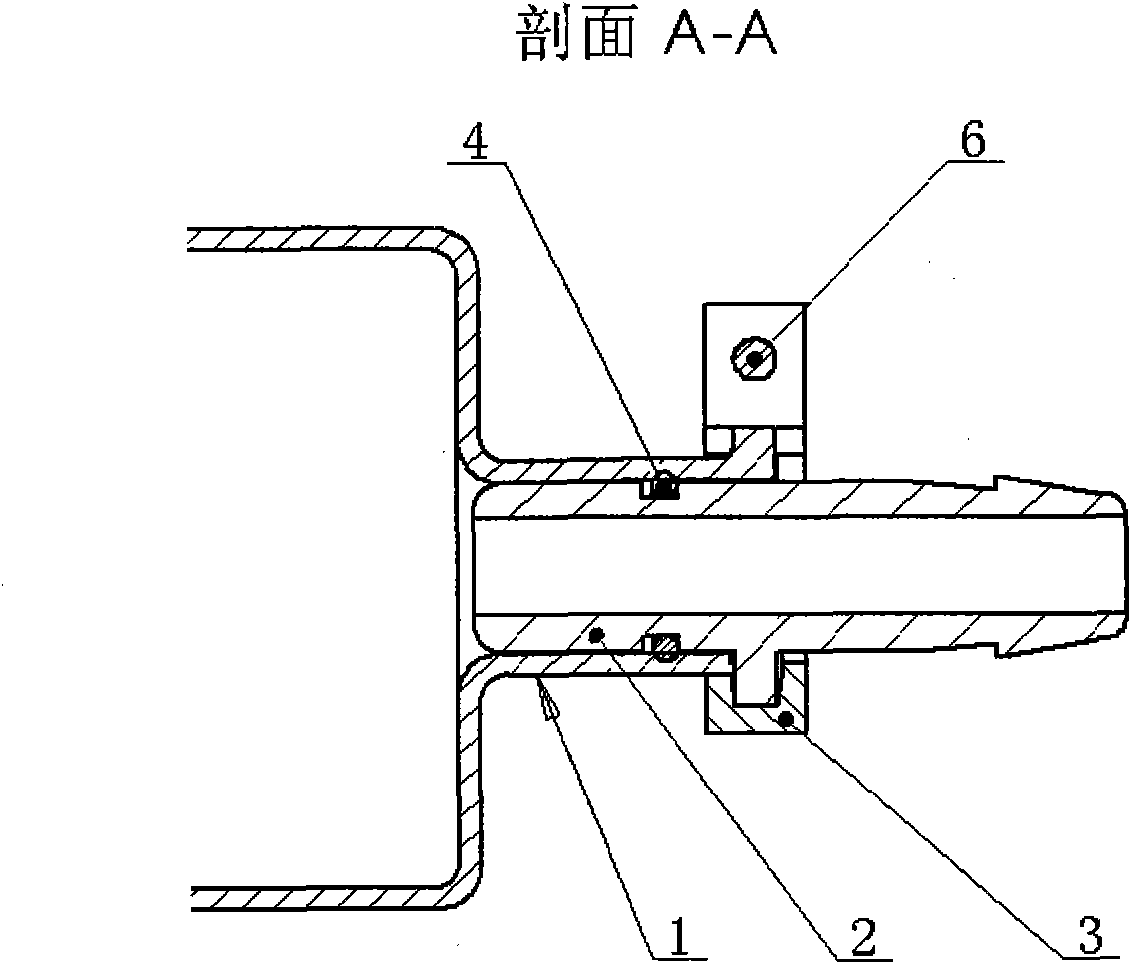

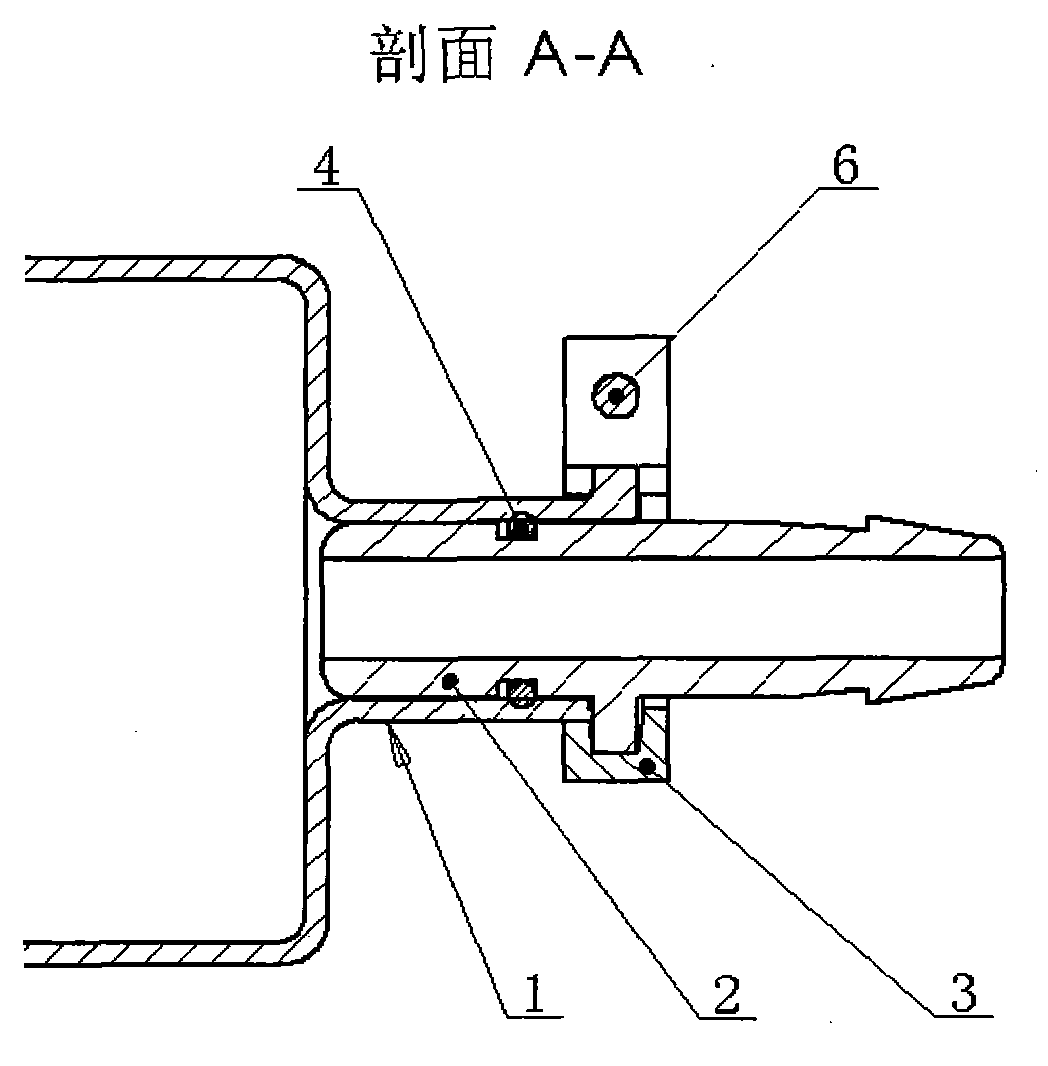

[0010] One, in figure 2 Among them, the end of the socket (1) of the desulfurizer is provided with a convex edge and a positioning gap is set on the convex edge; the left end of the connecting plug (2) is provided with an O-ring groove and an O-shaped rubber sealing ring (4); The positioning boss of the middle section of the plug is embedded in the positioning gap of the socket (1) of the desulfurizer; the connecting clamp (3) is stuck on the convex edge of the socket of the desulfurizer, and the connecting plug (2) is fixed on the desulfurizer On the socket; on the connecting clamp (3) there is a hexagonal nut groove to place the hexagonal nut (5), and the connecting clamp is locked by the fastening screw (6).

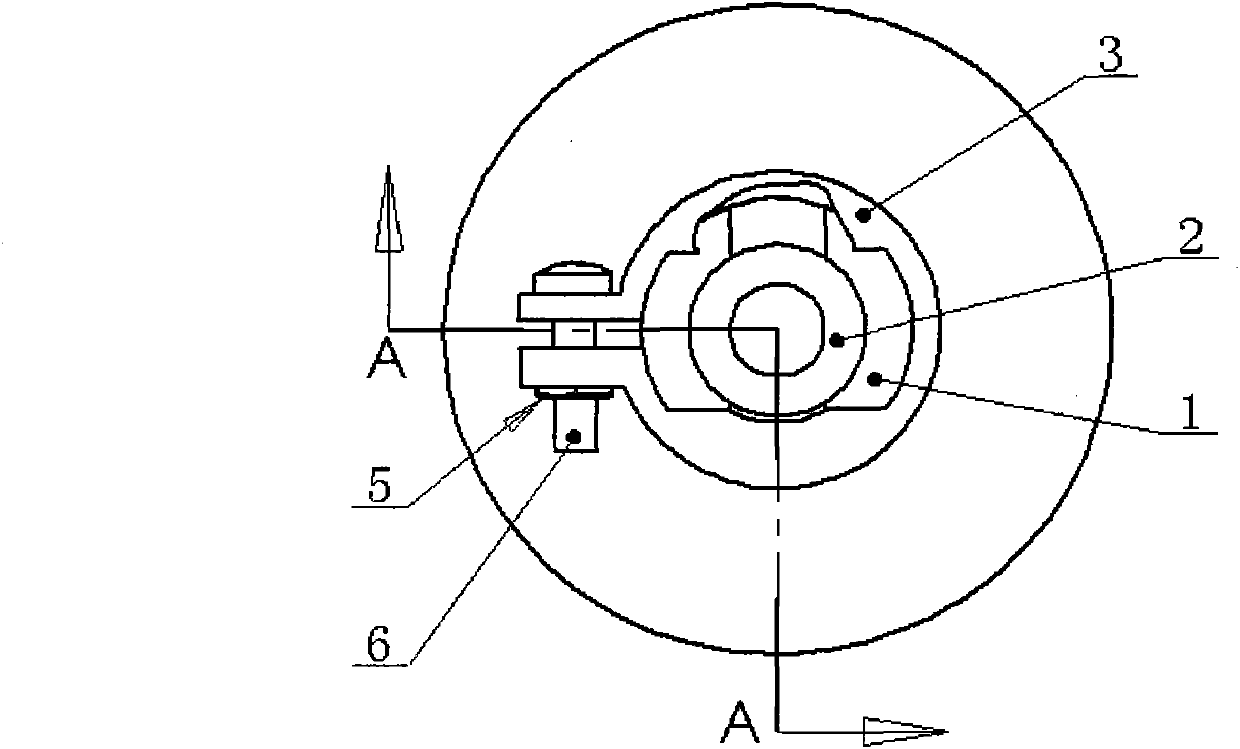

[0011] Two, in figure 1 , the connecting plug (2) is inserted into the socket (1), the positioning boss on the connecting plug is embedded in the positioning gap of the socket, the connecting clamp (3) is stuck on the convex edge, and the fastening screw is tightene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com