Full-automatic bearing outboard detector

An external detection and fully automatic technology, applied in the field of detection machines, can solve the problems of not having detection error self-calibration function and fault diagnosis and alarm function, and achieve the effect of good system stability, high measurement accuracy and reliable feedback function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

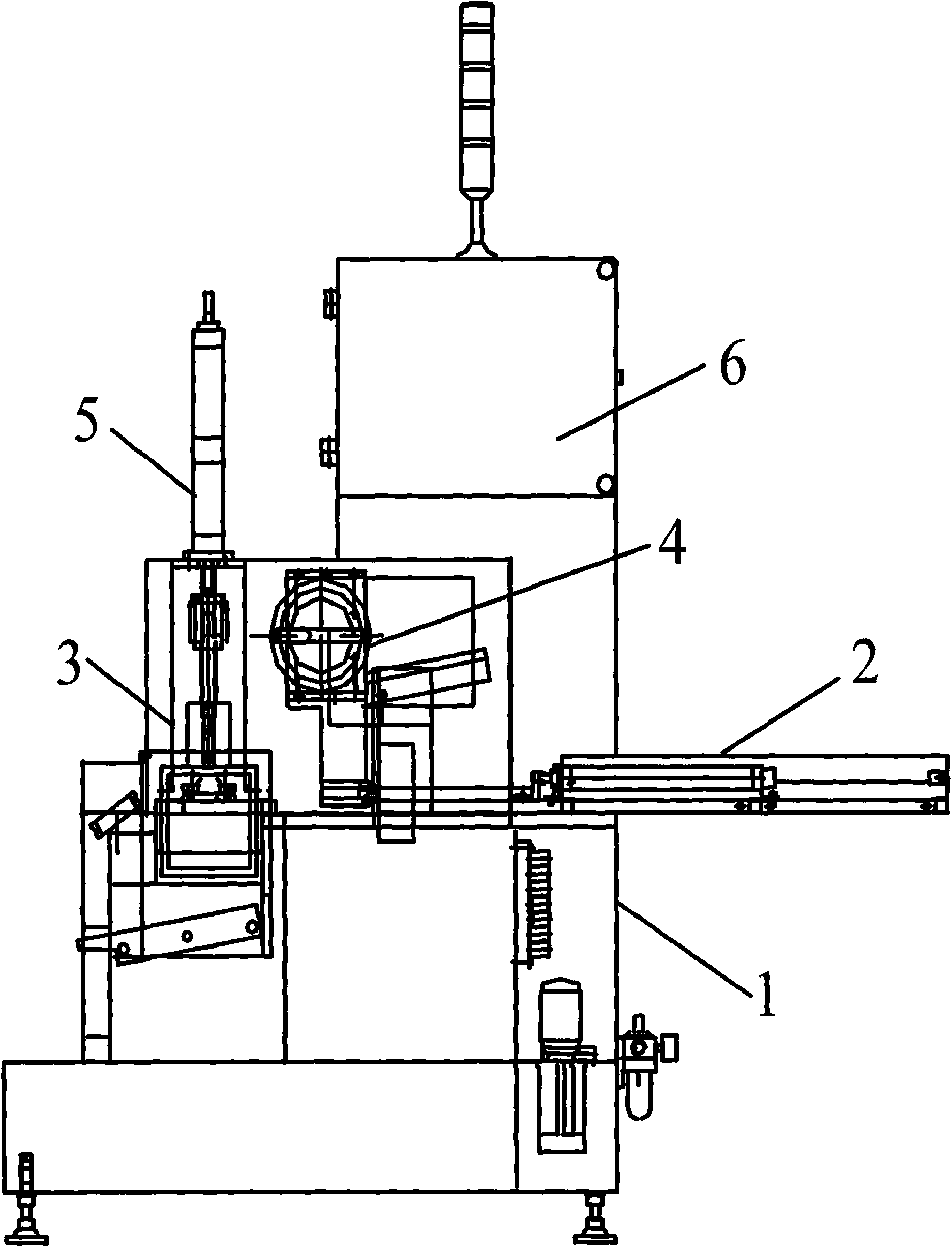

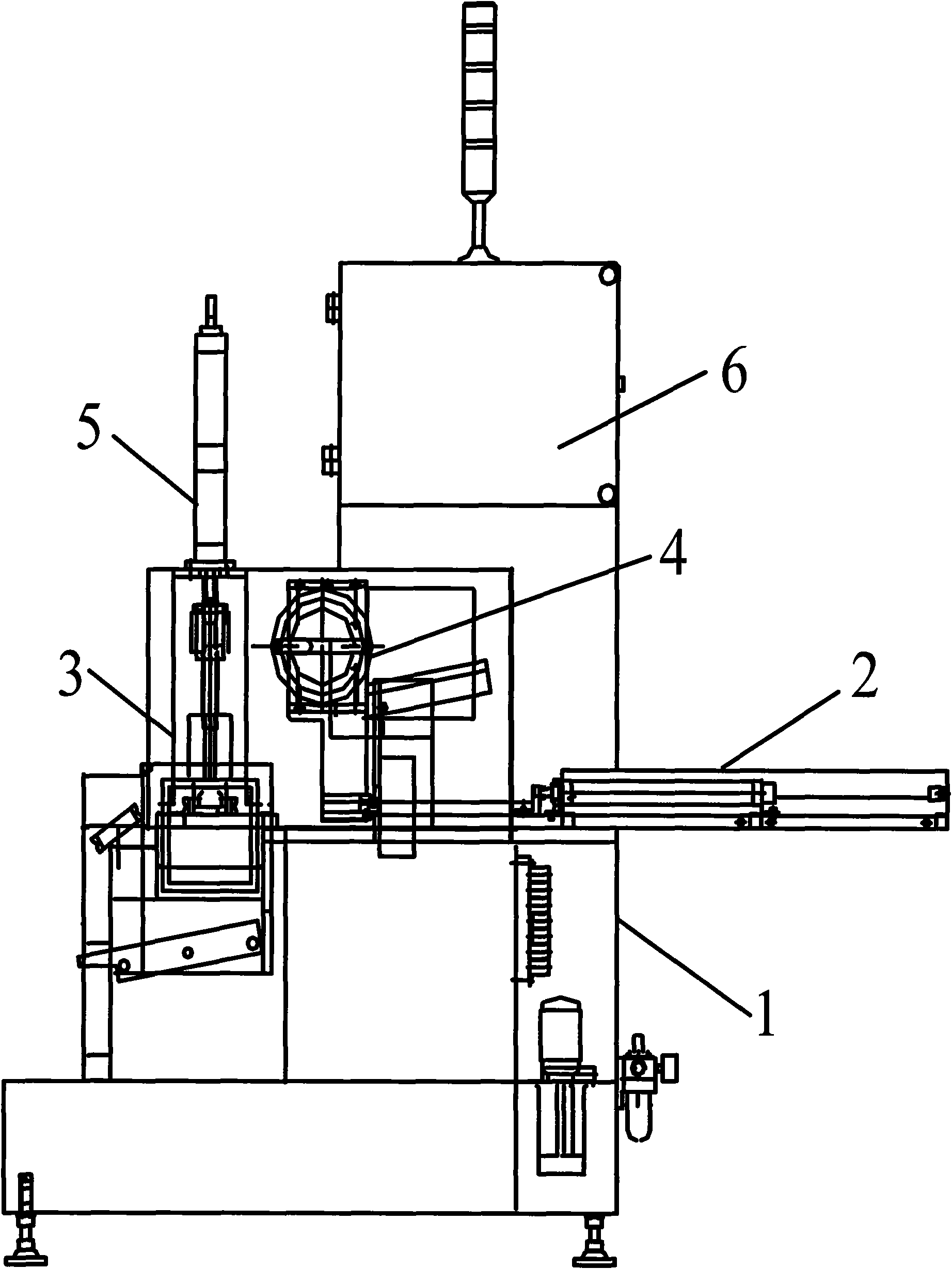

[0012] Such as figure 1 As shown, the automatic bearing external detection device of the present invention includes a fuselage 1, a feeding structure 2, a detection mechanism 3, a feeding mechanism 4, a feeding mechanism 5 and an electric box 6, and the feeding structure 2 and the detection mechanism 3 are respectively located in the fuselage On both sides of 1, the feeding mechanism 4 is located between the feeding structure 2 and the detection mechanism 3, the unloading mechanism 5 is located directly above the detection mechanism 3, and the electrical box 6 is located above the feeding mechanism 4. The fuselage 1 is welded with steel plates and tempered, so that it is firm and not deformed. The feeding structure 2 includes a pushing cylinder that simultaneously drives the measuring pushing block and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com