Oil cylinder-propelled drum type braking force test device

A testing device, a drum-type technology, applied in the direction of measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problems of high production cost, high device height, measurement error and complex structure of the whole machine, and achieve simple operation and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

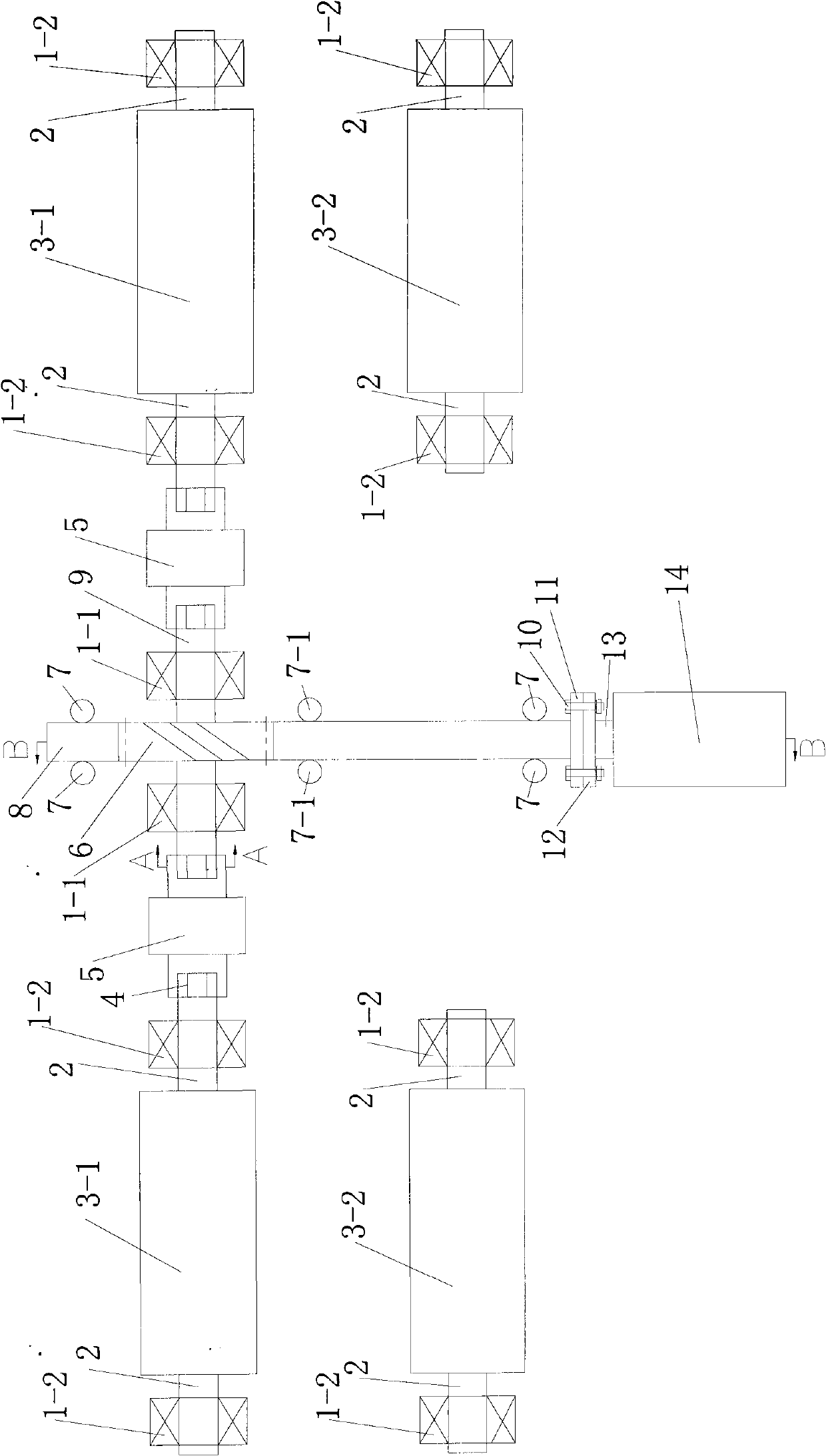

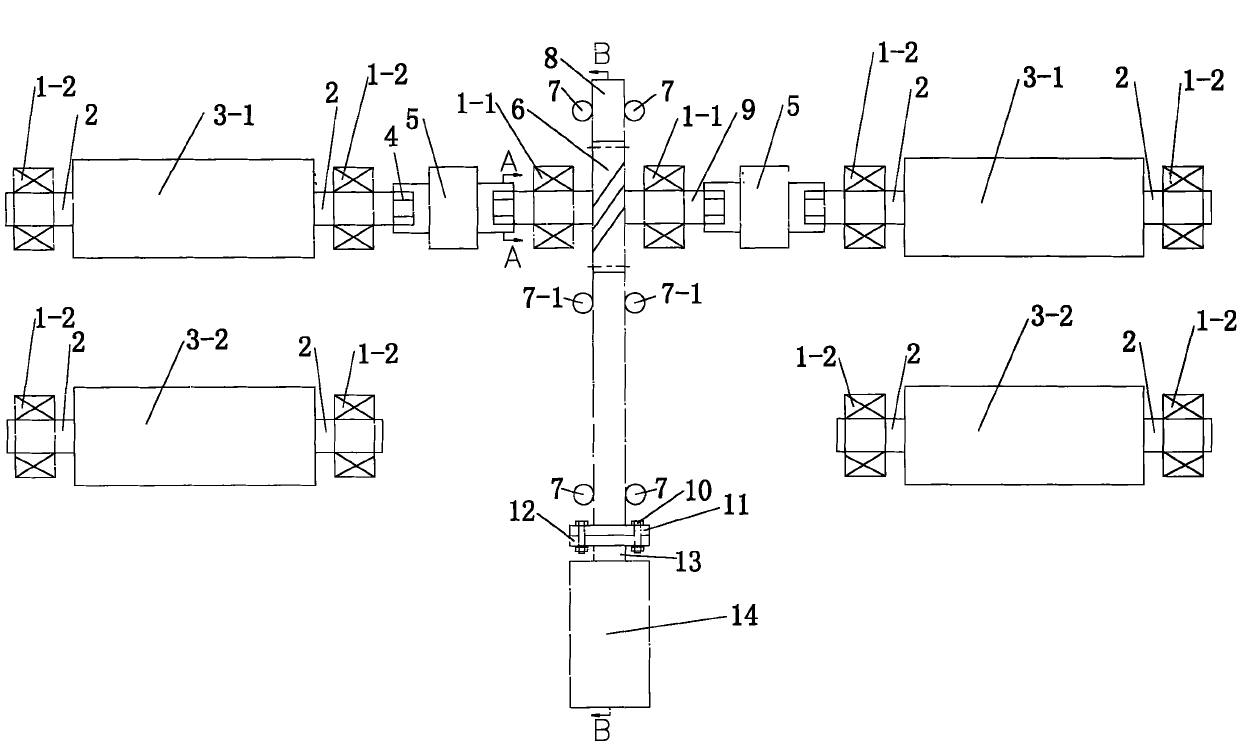

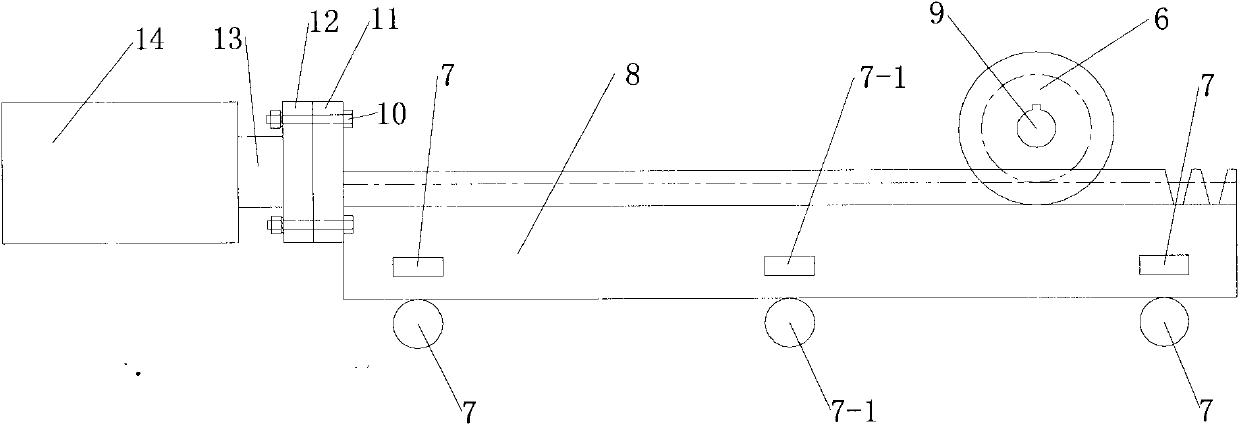

[0017] The drum-type braking force testing device driven by the oil cylinder of the present invention is composed of a hydraulic oil cylinder 14, a rack 8, a gear 6, a gear shaft 9, two braking and testing units and the like.

[0018] The hydraulic oil cylinder 14 is fixed on the frame (not shown in the figure) by bolts, which provides driving force for the testing device of the present invention. like figure 1 and figure 2 As shown, the piston flange 12 is welded on the outer end of the piston 13 of the hydraulic cylinder 14, and the rack flange 11 is welded on the end of the rack 8 close to the hydraulic cylinder 14, the piston flange 12 and the rack The flanges 11 are connected together by bolts, nuts and gaskets 10 . Thereby, the piston 13 of the hydraulic cylinder 14 is fixedly connected with the end of the rack 8 close to the hydraulic cylinder 14, so as to ensure that the driving force provided by the hydraulic cylinder 14 can act on the rack 8 through this connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com