Automatic feeding sealing verification process for electric power metering device

An electric power metering device and an automatic technology, applied in the direction of measurement device, identification device, measurement of electrical variables, etc., can solve the problems of manual sealing operation efficiency and the inability of personnel to meet work requirements, so as to improve efficiency and accuracy, avoid cumbersome, Achieve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

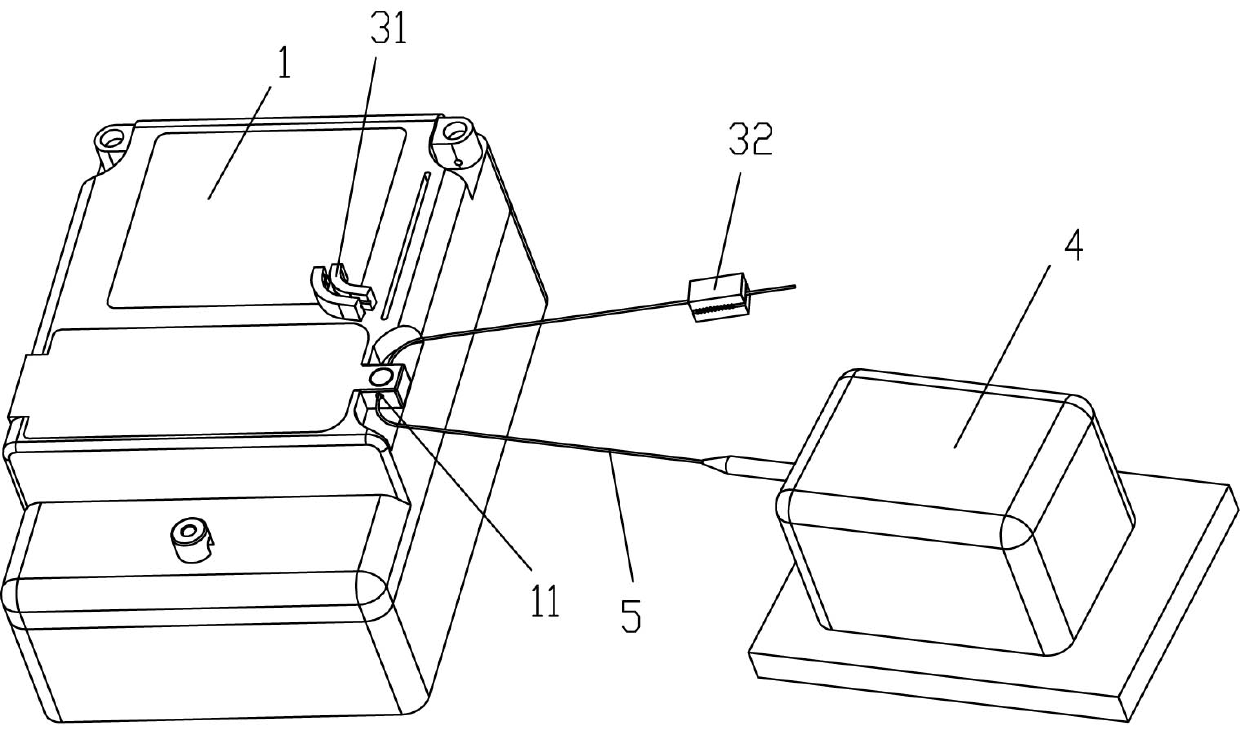

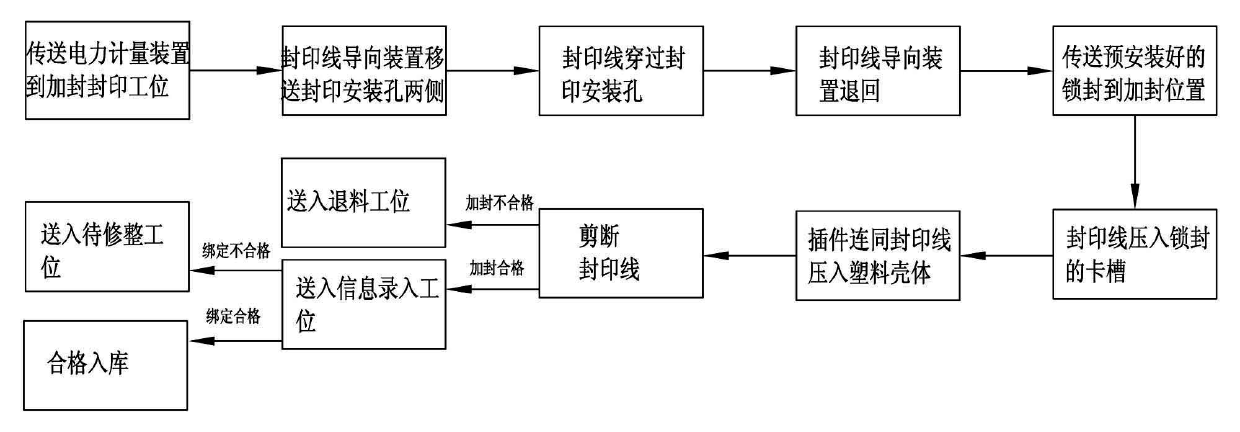

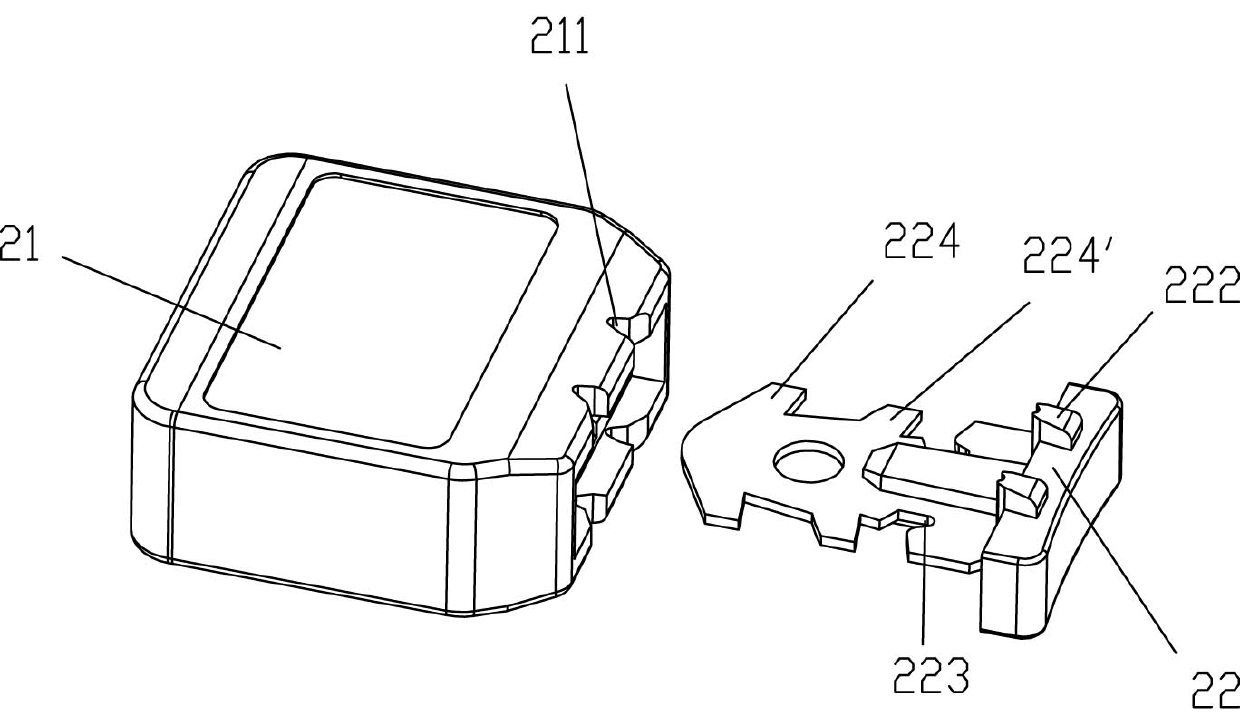

[0031] refer to Figure 1~Figure 8 , an automatic wire feeding and sealing verification process of a power metering device, which includes the following steps:

[0032] a) Clamp the power metering device 1 on the conveyor belt to the sealing station;

[0033] The clamping device is composed of X and Z axis electric cylinders and clamping electric hands. This device can realize the clamping of the power metering device 1 and the movement of the X and Z axes. When the detection device senses that the power metering device 1 is conveyed from the conveyor belt When reaching the predetermined position, the gripping device grips the power metering device 1 from the conveyor belt to the sealing station.

[0034] b) Move the seal line guide 3 to both sides of the seal installation hole 11 of the power metering device 1; Other structural forms are possible.

[0035] c) Using the seal line feeding device 4 to send the seal line 5 to the guide device 3 and pass through the seal instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com