Topping device

A ferrule and coil technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve problems such as time-consuming, troublesome coils, and poor production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

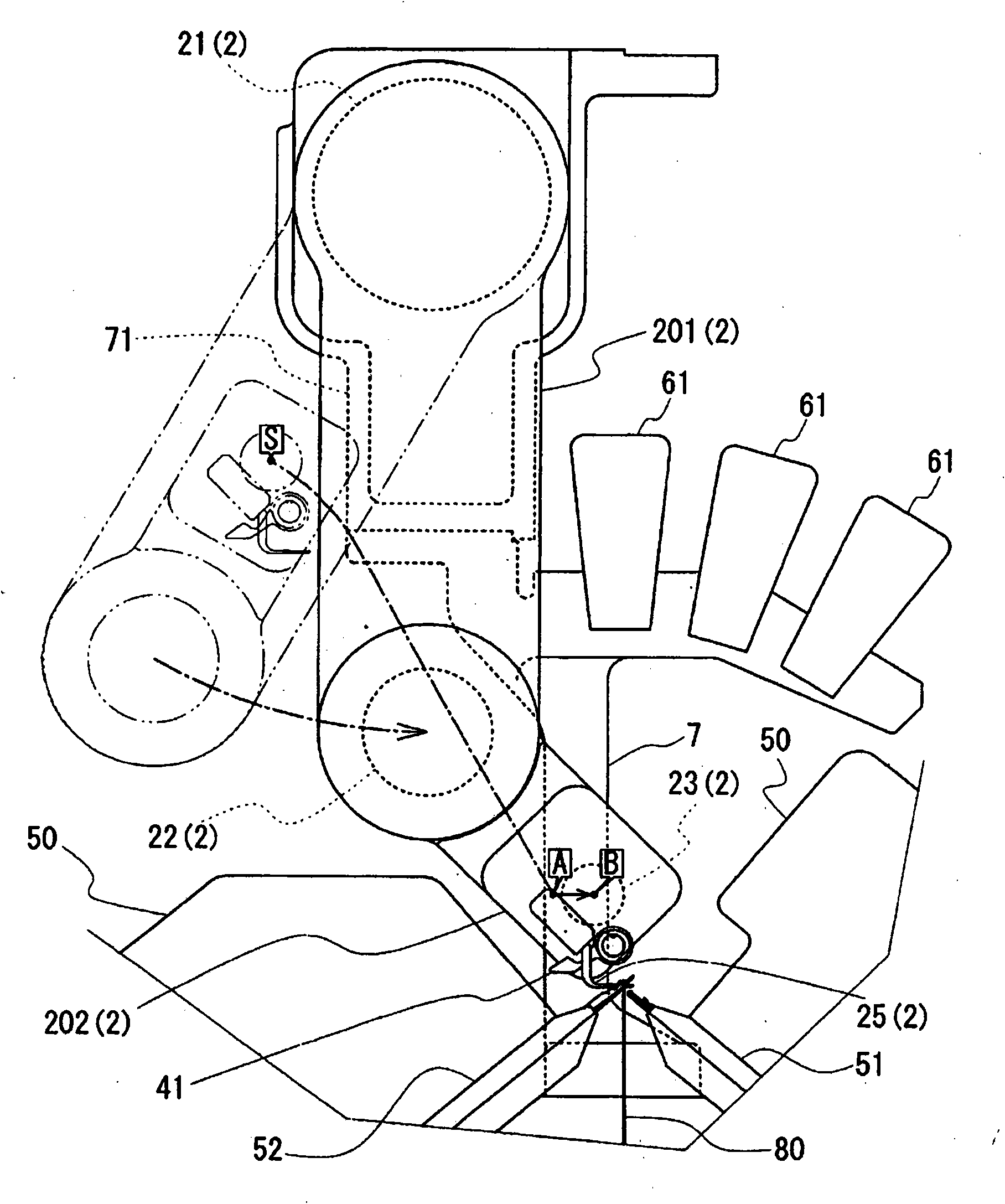

[0066] Embodiments of the present invention will be described below based on the drawings.

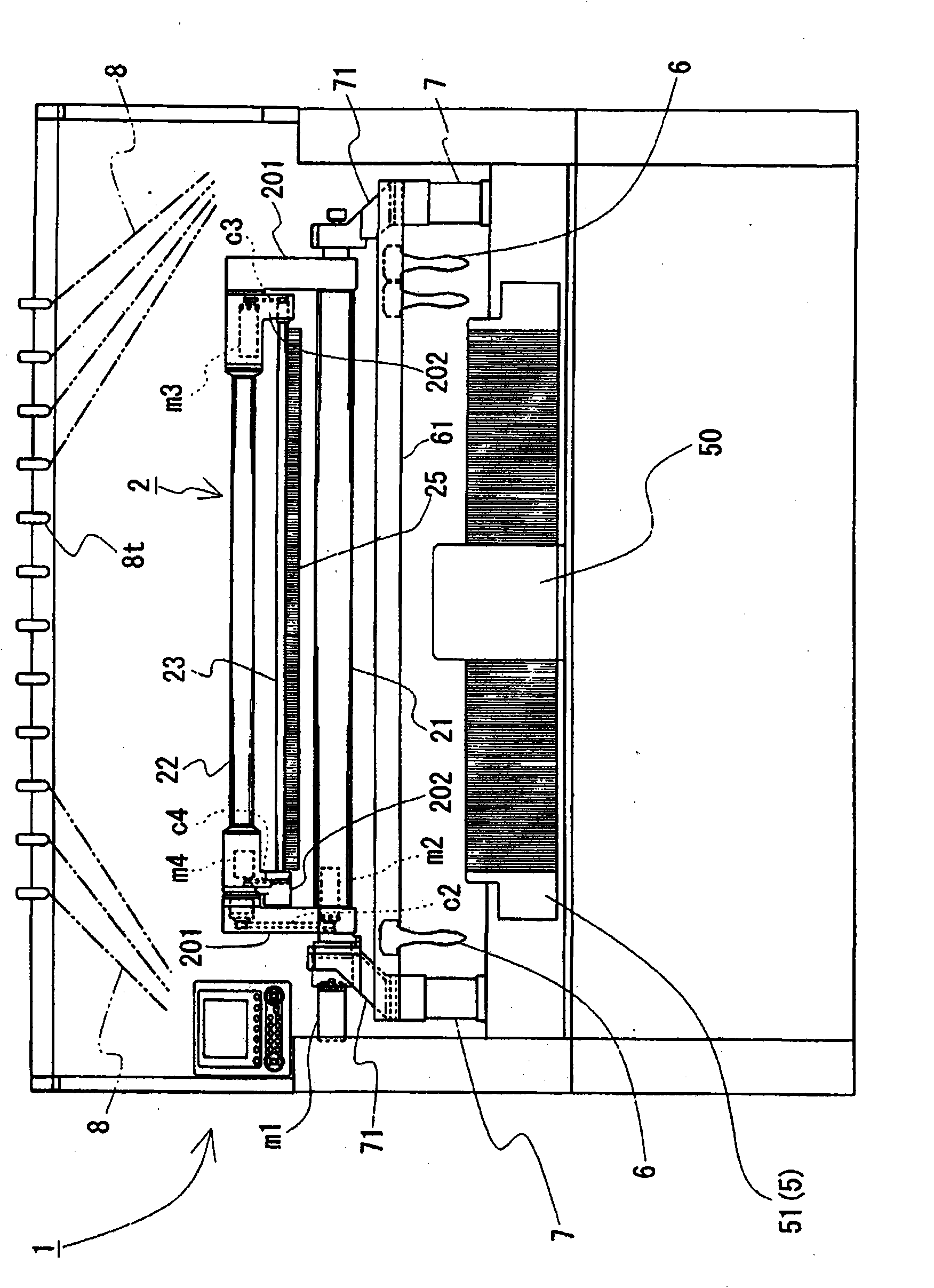

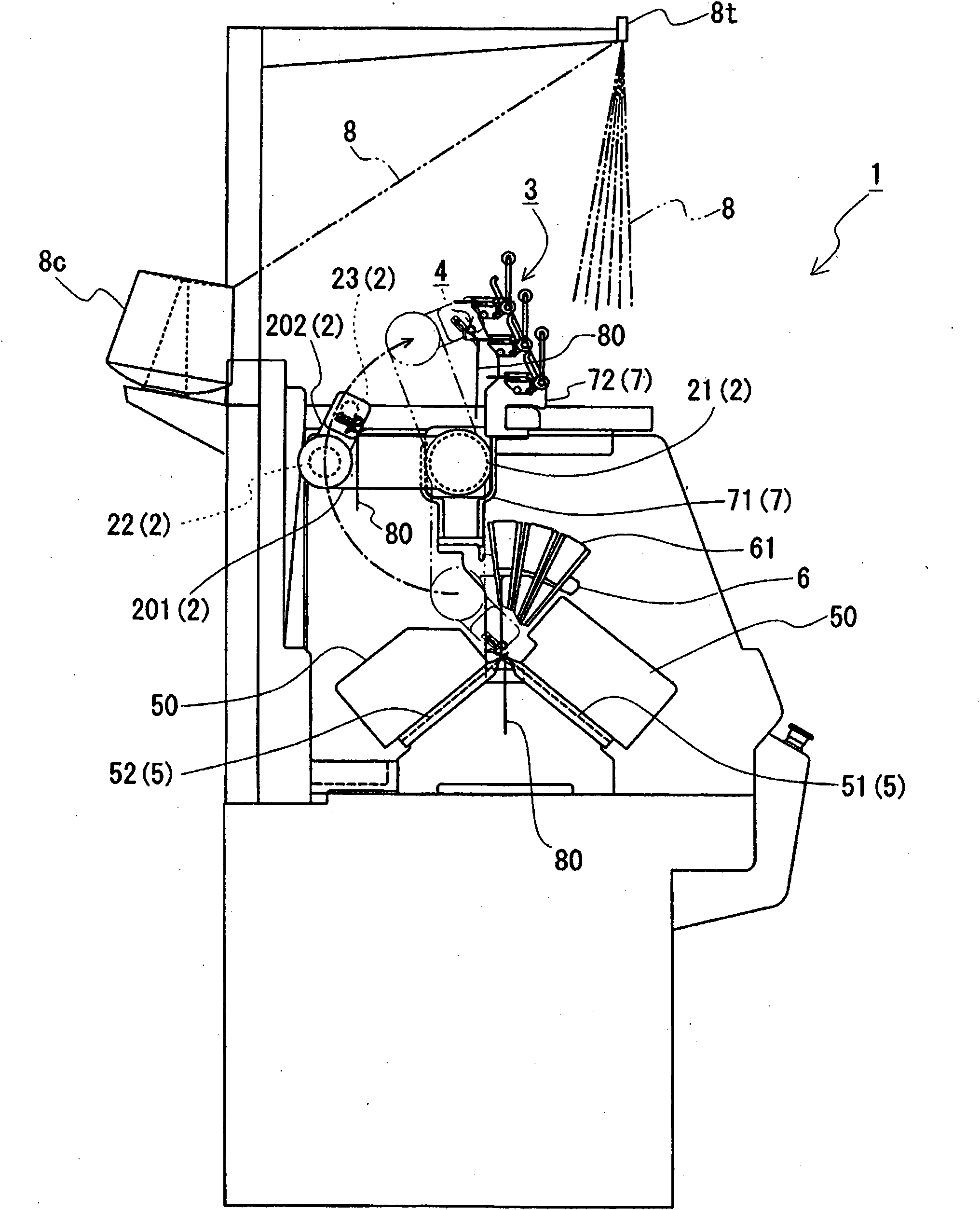

[0067] figure 1 It is a front view showing a flat knitting machine equipped with the loop device of the present invention. in addition, figure 2 It shows the left side view of the flat knitting machine equipped with the loop device of this invention.

[0068] The flatbed knitting machine 1 supplies the knitting yarn 8 from the yarn supplying member 6 to the needle bed between the front and rear pair of needle beds 5 (the front needle bed 51 and the rear needle bed 2 ) arranged oppositely, and is arranged in parallel on the needle beds. The knitting needle on 5 carries out the machinery of knitting fabric weaving. The knitting needle advances and retreats relative to the needle bed by the action of a cam system (not shown) mounted on the carriage 50 reciprocating on the needle bed 5, thereby performing three knitting operations of knitting, tucking, and non-knitting And the transfe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap