Linear stepping motor

A linear stepping, motor technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve problems such as manufacturing difficulties, and achieve the effect of reducing magnetic resistance, easy winding operation, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

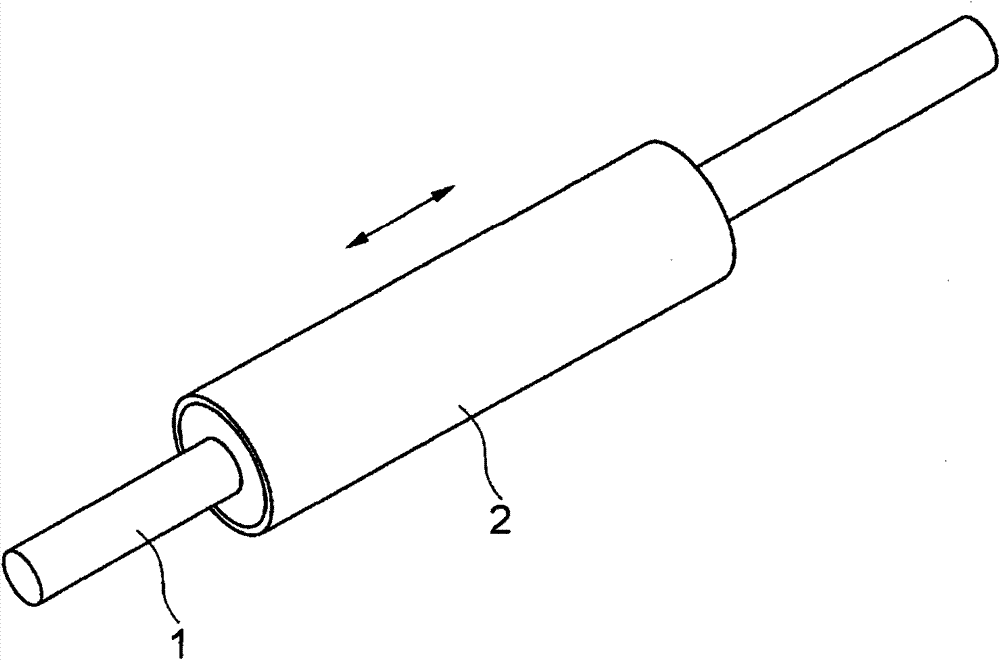

[0051] Hereinafter, embodiments of the present invention will be described in detail based on the drawings. figure 1 It is a linear stepping motor which shows 1st Embodiment of this invention. The linear stepping motor is composed of a column body 1 extending elongatedly and a cylindrical mover 2 covering the periphery of the column body 1 . The cylinder 1 functions as a field magnet of the linear stepping motor, and the mover 2 functions as an armature (motor). The cylinder 1 moves relatively linearly in the axis direction relative to the mover 2 . One of column 1 or mover 2 is fixed while the other moves.

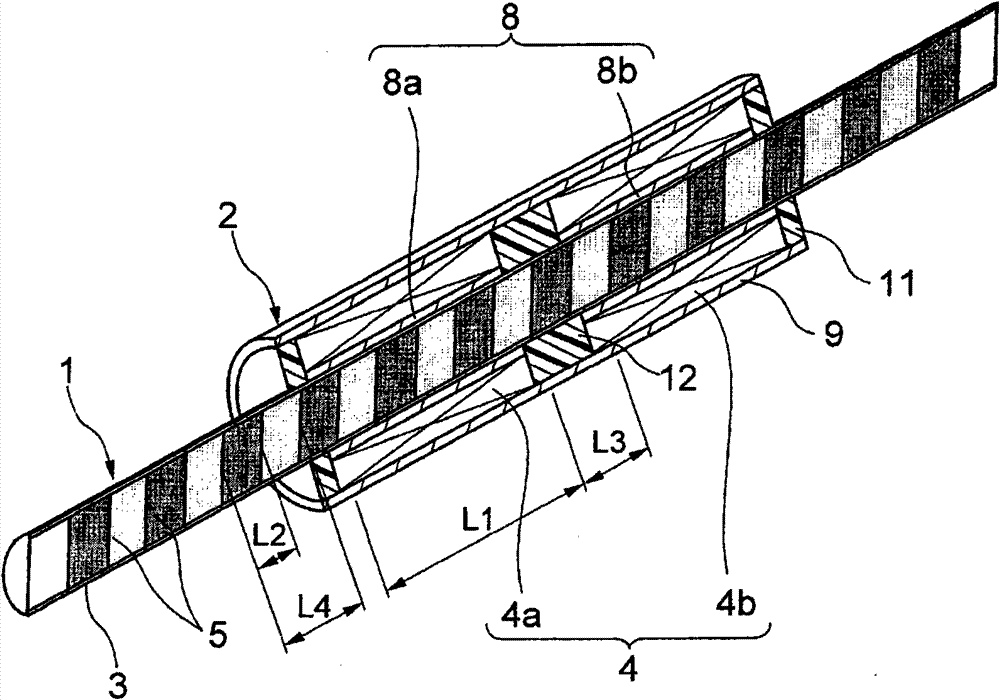

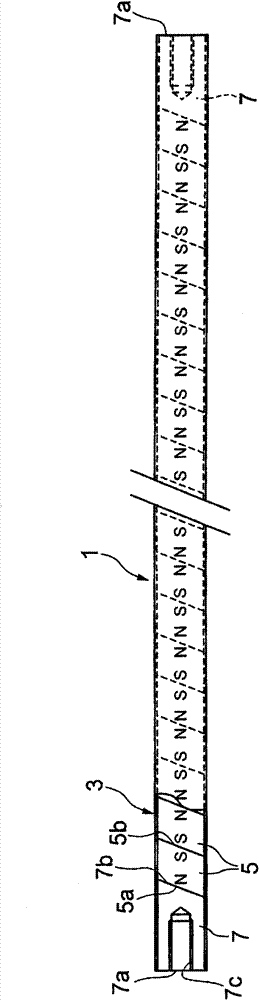

[0052] figure 2 It is a sectional view showing a linear stepping motor. In the cylinder 1, the magnetic poles of N pole and S pole are alternately magnetized in the axial direction. A two-phase coil 4 wound around the cylinder 1 with a gap is accommodated in the mover 2 . The two-phase coil 4 is constituted by a pair of coils 4a and 4b of each phase arranged side b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com