Pneumatic device for intravenous infusion

A drip and air pressure technology, applied in the direction of pressure infusion, the introduction of instruments into the body, etc., can solve the problems of inconvenience, sitting on the bed or chair, etc., and achieve the effect of easy replacement, convenient portability and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

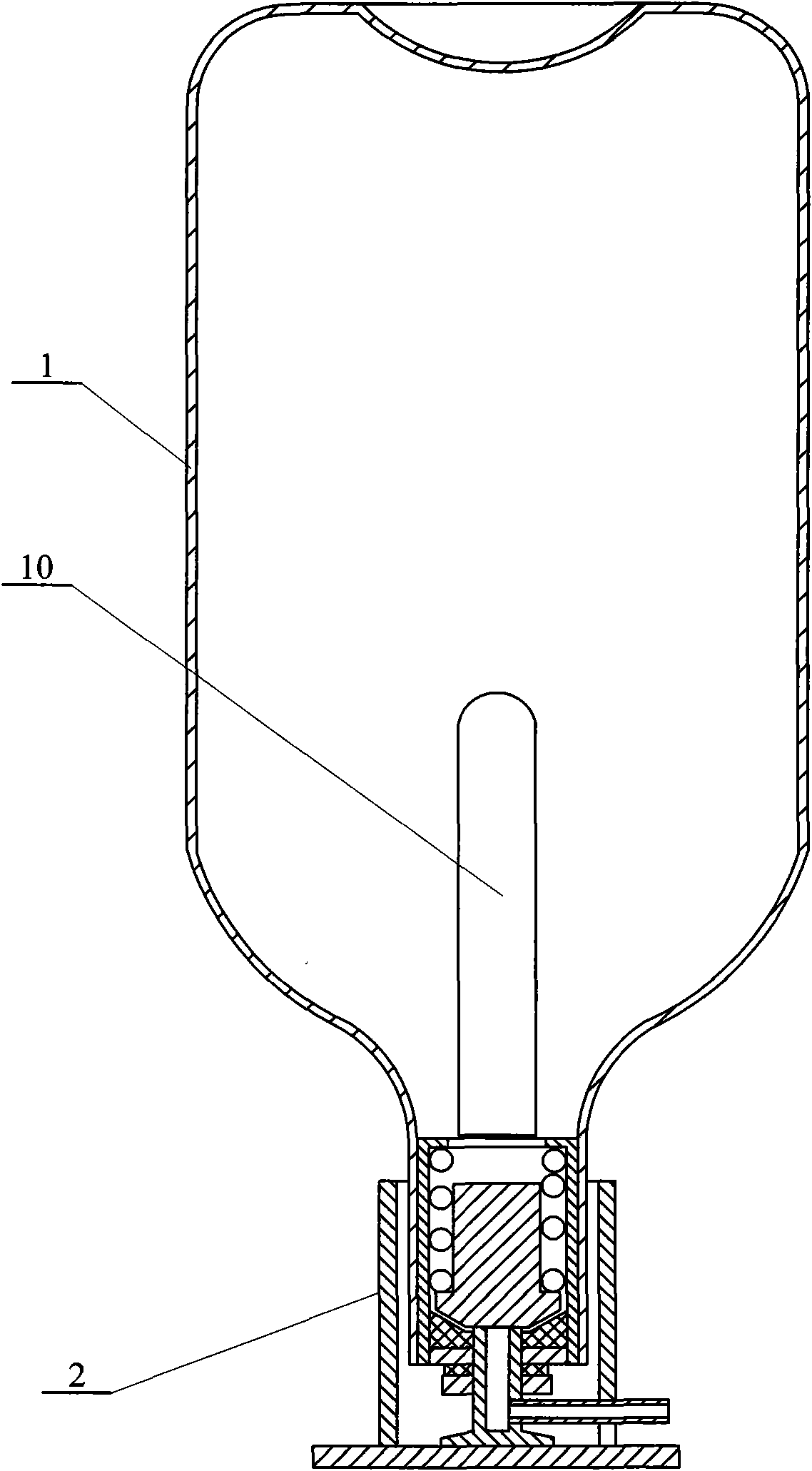

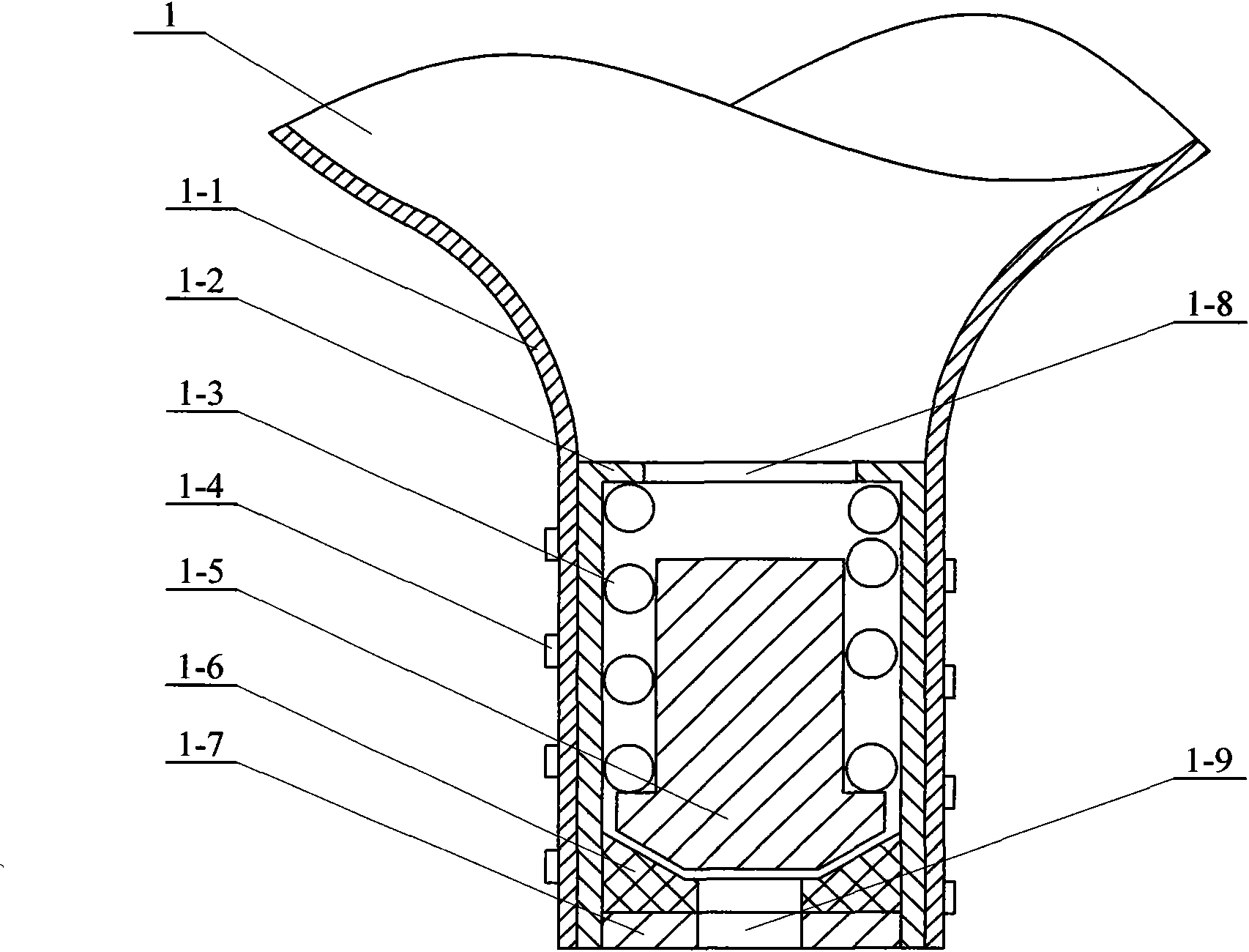

[0015] Specific implementation mode 1: Combination Figure 1 ~ Figure 3 To describe this embodiment, this embodiment includes a gas storage tank body 1 and an air outlet nozzle 2, and the gas storage tank body 1 and the air outlet nozzle 2 are screwed or inserted.

[0016] The gas storage tank body 1 includes a tank body 1-1, a spring seat 1-2, a spring 1-3, a plug 1-5, a gasket 1-6, and a tank mouth stopper 1-7. The spring seat 1-2 is fixed on the tank In the can mouth of the body 1-1, the spring 1-3 and the plug 1-5 are arranged in the spring seat 1-2, the can mouth stopper 1-7 is fixed on the outermost end of the spring seat 1-2, and the sealing gasket 1- 6 is fixed on the inner side of the can mouth baffle 1-7, the sealing gasket 1-6 is matched with the plug 1-5, and the outer side of the can body 1-1 is provided with an external thread 1-4.

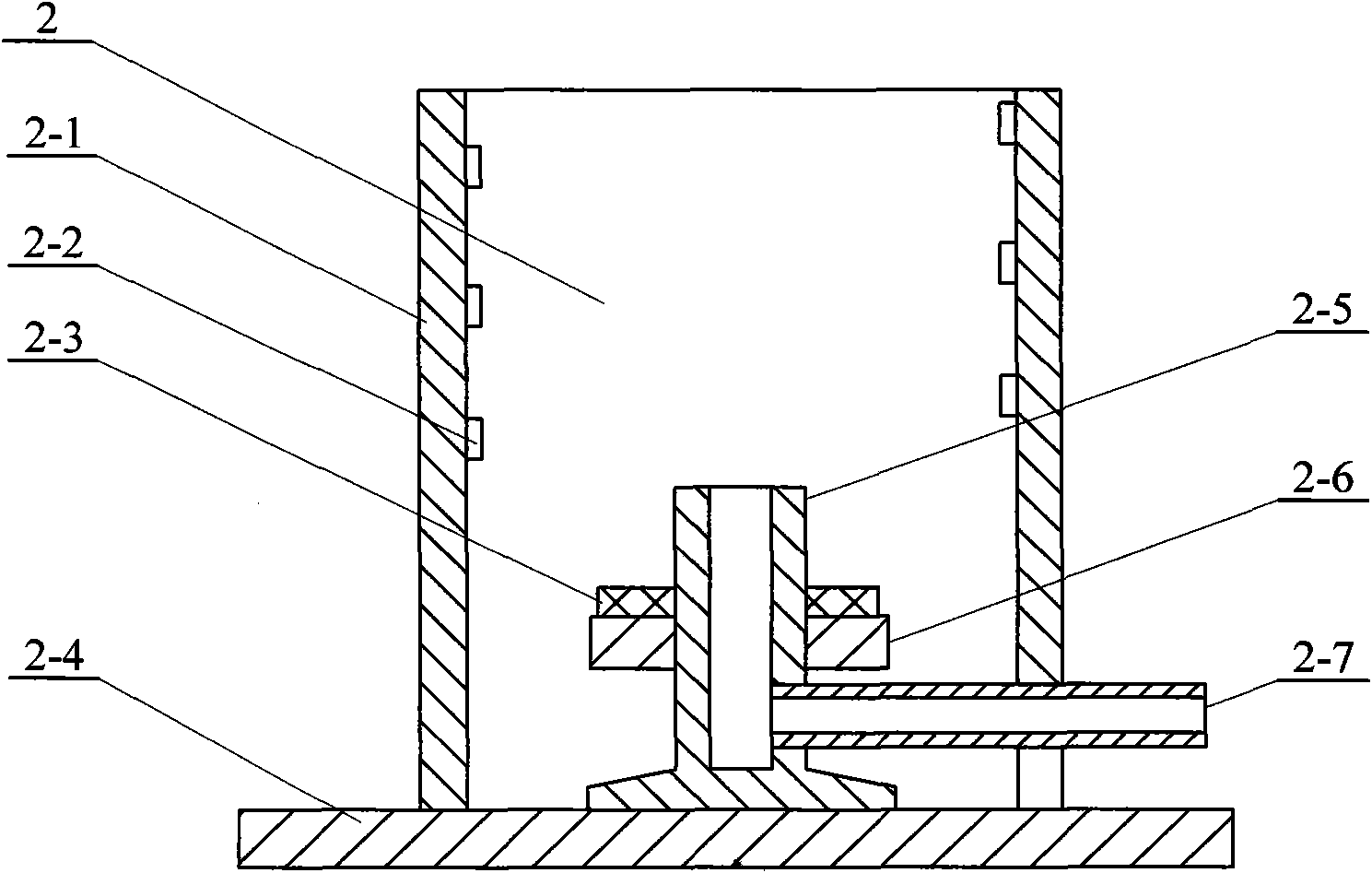

[0017] The air outlet 2 includes a cylinder 2-1, a plastic cushion 2-3, a base 2-4, a top valve 2-5, a plastic cushion seat 2-6 and an a...

specific Embodiment approach 2

[0018] Specific implementation manner two: combination Figure 7 To describe this embodiment, the gas tank body 1 of this embodiment includes a tank body 1-1, a stop 1-11, a check valve body 1-12, a check valve spring 1-13, and a glass ball 1-14 , Tank cover 1-16 and sealing ring 1-17, tank cover 1-16 and tank mouth of tank body 1-1 are screwed together, there will be a check valve between tank cover 1-16 and tank mouth of tank body 1-1 The bottom edge 1-18 of the valve body 1-12 is clamped, and the bottom edge 1-18 of the valve body 1-12 of the one-way valve is provided with a sealing ring 1-17 between the mouth of the tank 1-1 The valve spring 1-13 and the glass ball 1-14 are arranged in the valve body 1-12 of the one-way valve, and the stop 1-11 is fixed on the upper end of the valve body 1-12 of the one-way valve. Vent holes 1-15 are opened on 1-12.

[0019] The air outlet 2 includes a vent pipe 2-12, a sealing ring 2-13, a bracket 2-14, a non-reverse claw 2-15, and a vent p...

specific Embodiment approach 3

[0021] Specific implementation mode three: combination figure 1 with Figure 7 To explain this embodiment, this embodiment also includes a pressure indicator 10, which is arranged in the tank body 1-1. The pressure indicator 10 is composed of a transparent tube 10-1 and a piston 10-2, and the piston 10-2 is arranged in the transparent tube. In 10-1, a scale is provided on the outer surface of the transparent tube 10-1. The tank body 1-1 can be made of plastic. The pressure indicator 10 is fixed in the tank body 1-1. After the tank body 1-1 is inflated, the pressure inside the tank body 1-1 increases, causing the piston 10-2 to move inward. Push forward, otherwise exit outward. The scale on the front of the piston is the pressure value in the tank. Others are the same as the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com