Production method of steel blade of counter rotating axial main fan

A production method and a fan technology, which are applied to the components of the pumping device for elastic fluid, mechanical equipment, non-variable-capacity pumps, etc., can solve the problem of loose steel blade rivets, safe operation of the main fan, and safe production in coal mines. , leaves falling off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

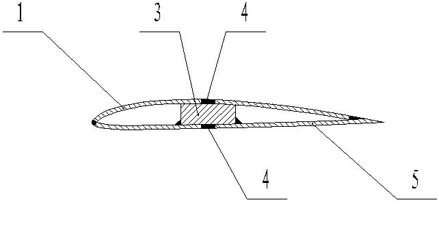

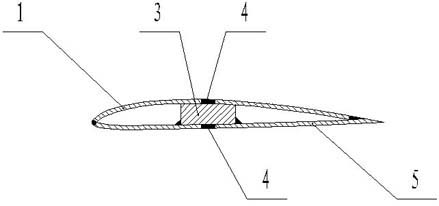

[0006] exist figure 1 Among them, the upper blade 1 and the lower blade 5 are provided with welding holes 4 for plug welding, and the petiole 3 is connected between the upper blade 1 and the lower blade 5 . When making the steel blade, first the junction of the lower blade 5 and the petiole 3 is welded with fillet welding, and then the welding hole 4 of the lower blade 5 is welded with the petiole 3 by plug welding. Then the junction of the upper blade 1 and the lower blade 5 front and rear edges is welded, and the welding hole 4 on the upper blade 1 is welded with the petiole 3 by plug welding. Finally, the top and root of the leaves are sealed. There can be one or more welding holes 4 on the upper blade 1 and the lower blade 5 .

Embodiment 2

[0008] exist figure 1 Among them, the upper blade 1 and the lower blade 5 are provided with welding holes 4 for plug welding, and the petiole 3 is connected between the upper blade 1 and the lower blade 5 . Firstly weld the joints around the upper blade 1 and the petiole 3 by fillet welding, then weld the welding hole 4 of the upper blade 1 to the petiole 3 by plug welding, and connect the front and rear edges of the upper blade 1 and the lower blade 5 The junction of the joint is welded, and then the welding hole 4 of the lower blade 5 is welded with the petiole 3 in a plug welding manner. Finally, the top and root of the leaves are sealed. This welding method prevents the blade from falling off the petiole. It plays an important role in improving the safety and reliability of the main ventilator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com