Xenon lamp

A xenon lamp and lamp holder technology, applied in the field of xenon lamps, can solve the problems of not finding a technical solution, cumbersome assembly, waste of resources, etc., and achieve the effect of ensuring that the light is not reduced, the working temperature is stable, and the use cost is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

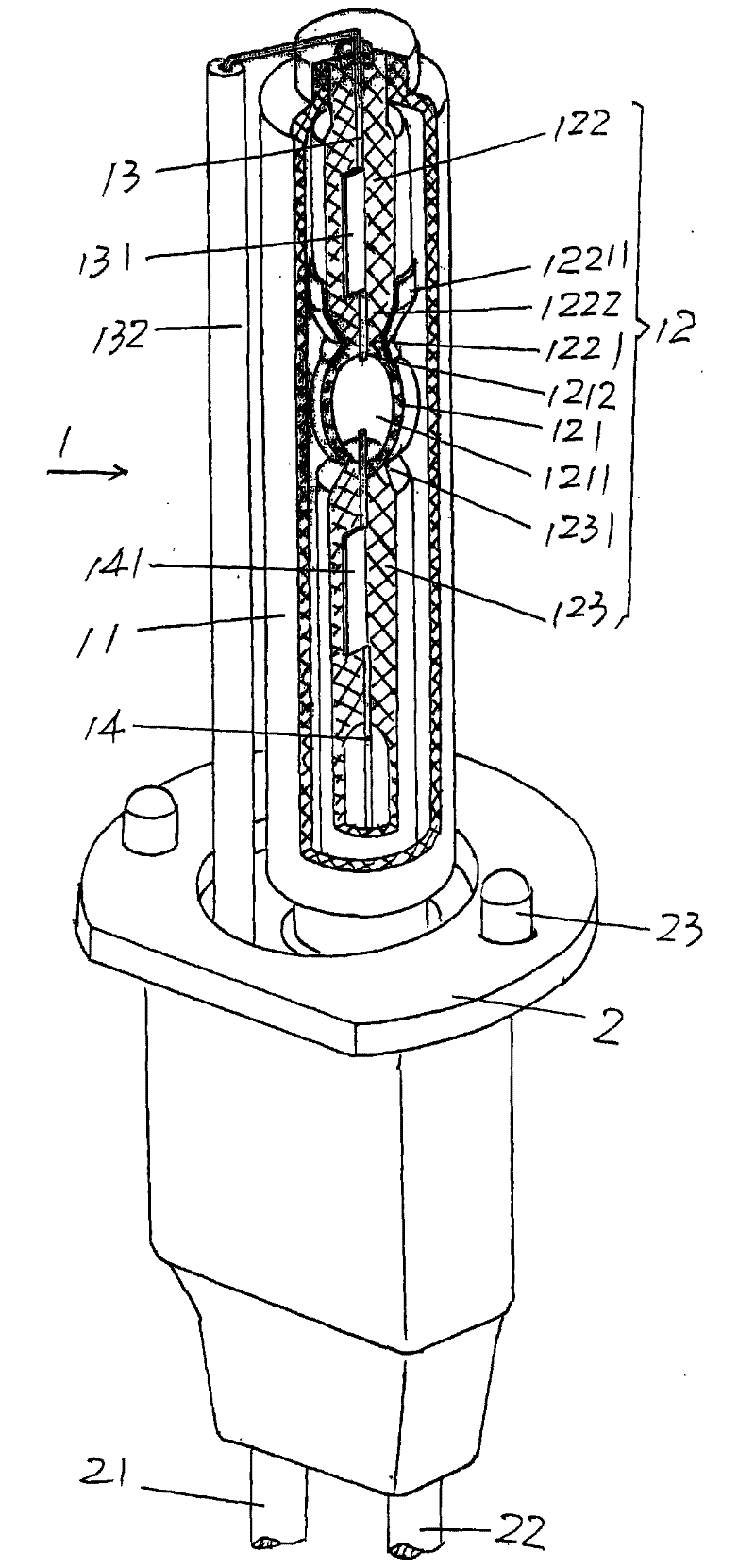

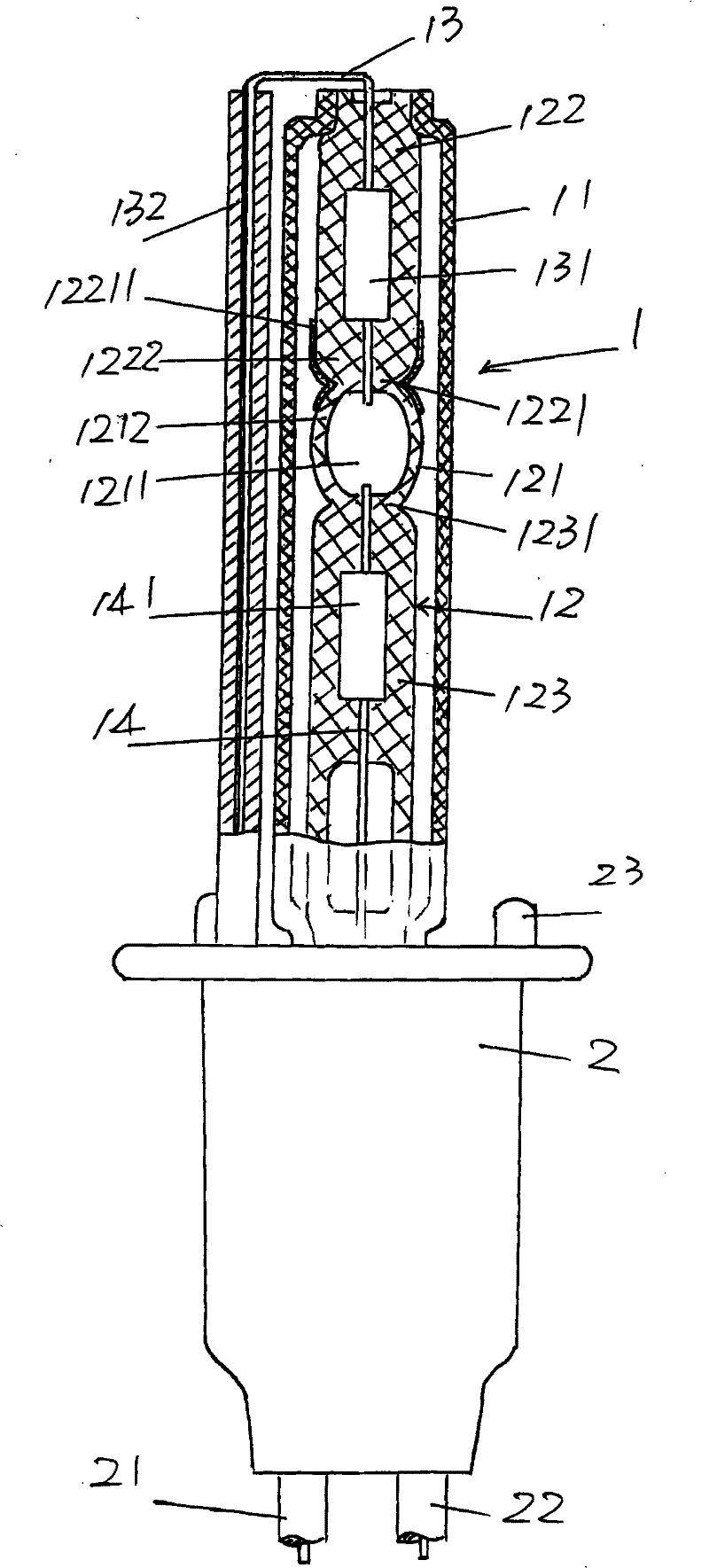

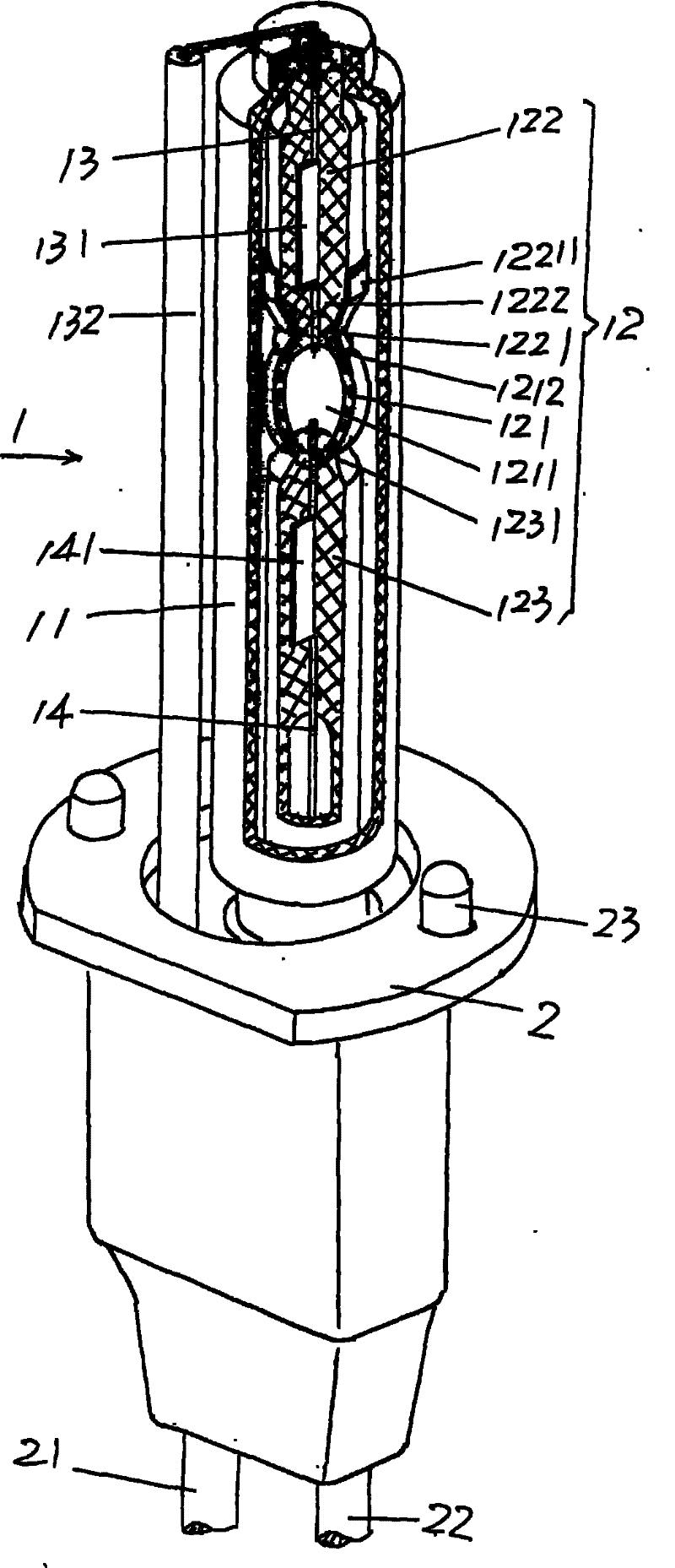

[0016] please see figure 1 and figure 2 , provides a lamp body 1 and a lamp holder 2, the lamp body 1 and the lamp holder 2 are fixed, and a pair of flanges 23 on the lamp holder 2 are used for installation. The lamp body 1 includes a protective glass tube 11, a glass core tube 12, and cathode and anode wires 13, 14. The protective glass tube 11 can also be called an outer glass tube and is fixed with the lamp holder 2. The glass core tube 12 is located inside the protective glass tube 11. The material of the glass core tube 12 is quartz glass containing titanium oxide, which is composed of a discharge tube segment 121 having a discharge cavity 1211 and a discharge tube segment 121 filled with xenon gas in the discharge cavity 1211, and first and second core tube segments 122, 123, Among them: the discharge tube section 121 is an elliptical capsule structure, the aforementioned discharge chamber 1211 is in a closed state, and xenon gas is filled in the discharge chamber 1211...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com