Anti-contraction optical cable and production method thereof

A manufacturing method and anti-shrinkage technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of difficult stripping, high price, and low yield of optical cables, and achieve the effects of wide temperature range, simple manufacturing process, and high qualified rate of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

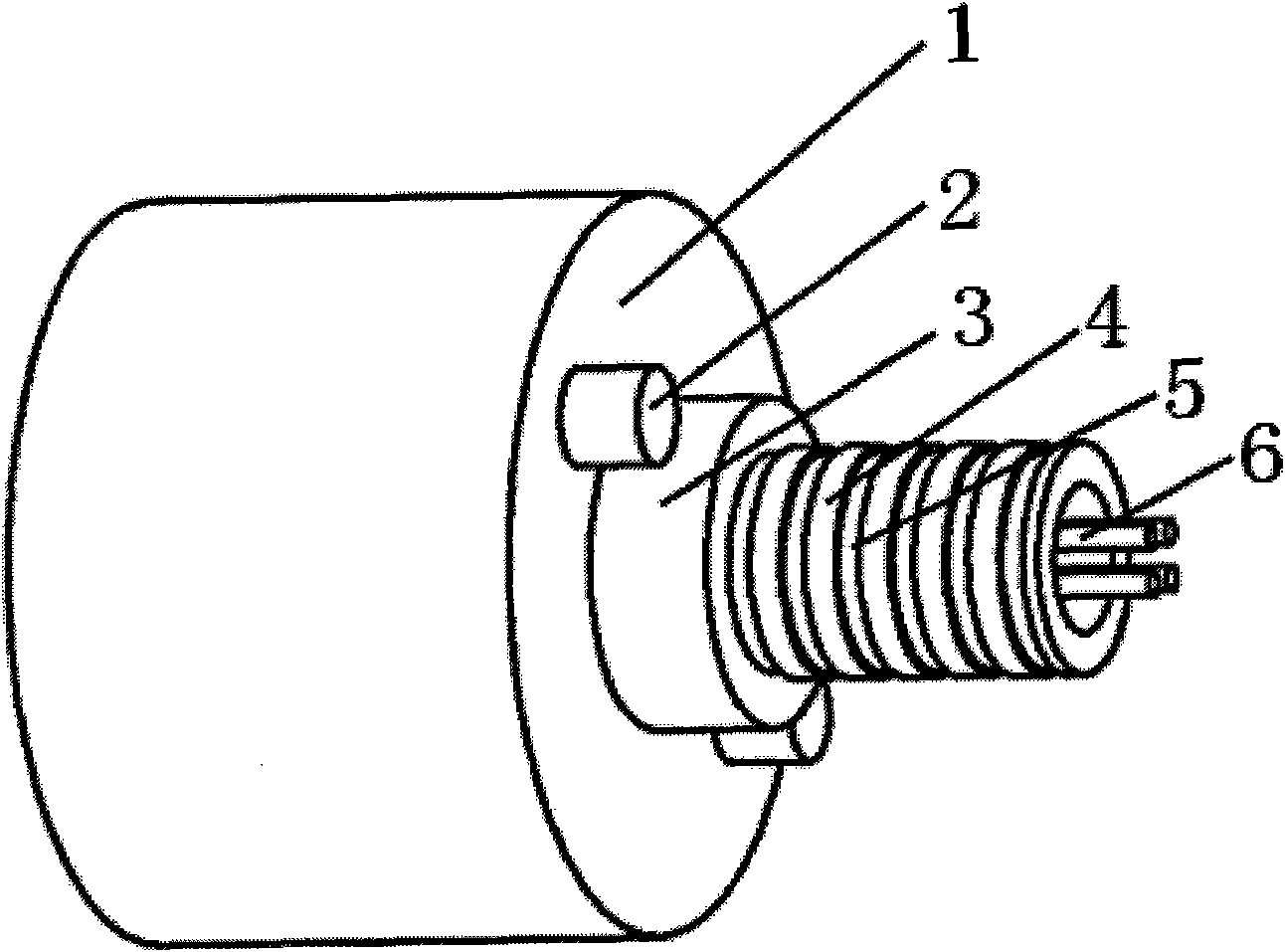

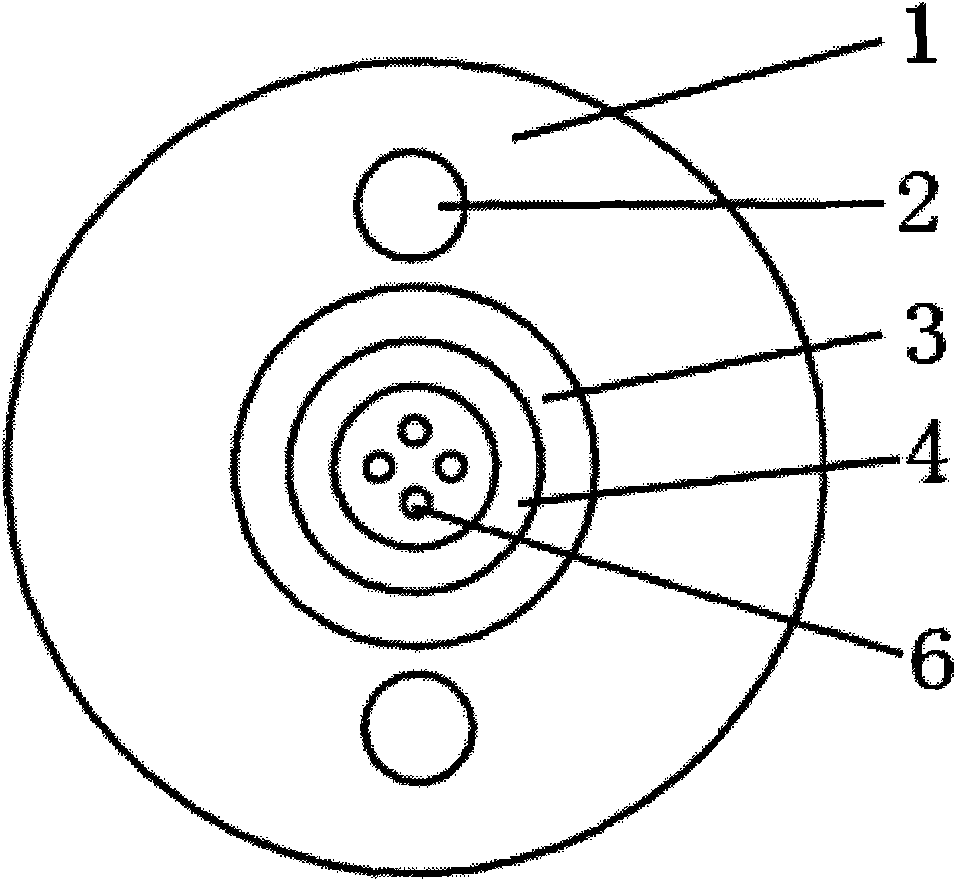

[0042] see Figure 1-Figure 3 , shrink-proof optical cable, which includes: a loose tube located in the center of the cable; a protective layer 3 covering the loose tube; a sheath layer 1 coated outside the protective layer; located between the sheath layer and the protective layer and a plurality of optical fibers 6 inside the loose tube; it is characterized in that: the outer surface of the loose tube is successively distributed with tube bodies 4 and grooves 5; the inner surface of the protective layer has corresponding The protrusion; the gap between the loose tube and the protective layer is filled with water blocking material. The groove is annularly penetrating through the outer surface of the loose tube, and does not go through the tube wall of the loose tube.

Embodiment 2

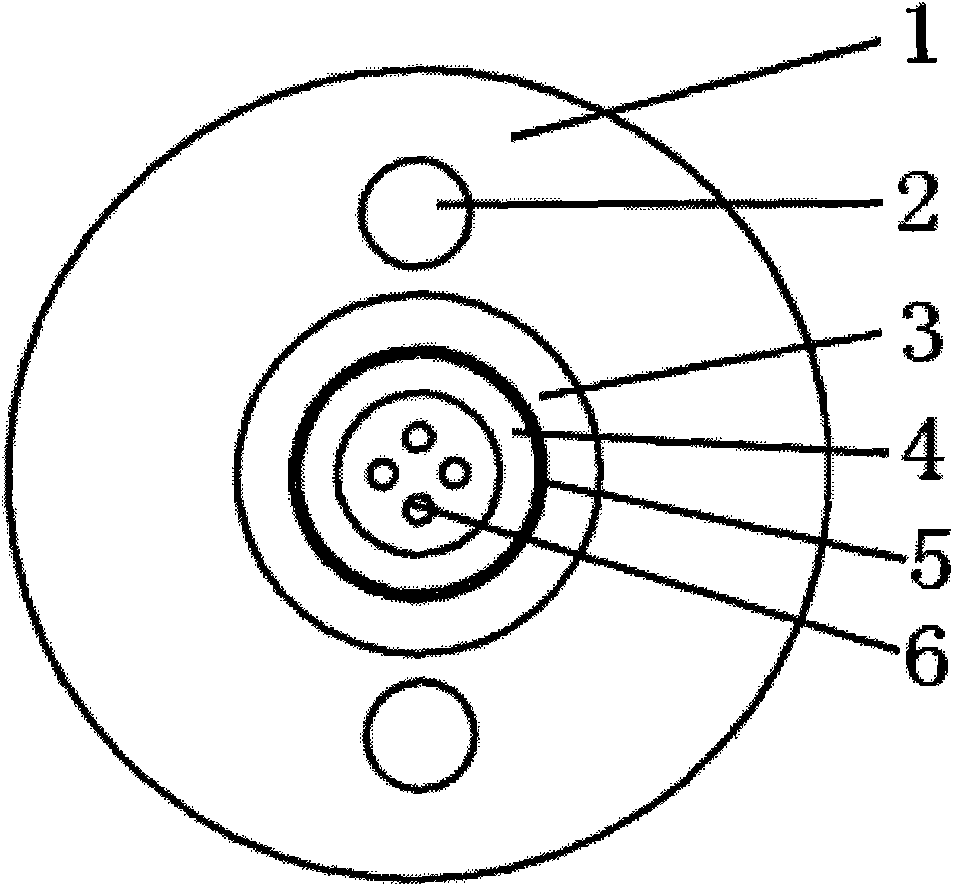

[0044] see Figure 4-Figure 6, which is basically the same as the first embodiment, except that the groove is partially cut on the outer surface of the loose tube, and does not penetrate through the wall of the loose tube.

Embodiment 3

[0046] see Figure 7 , and refer to Figure 5 and Image 6 , which is basically the same as the second embodiment, except that the width of the groove is narrower and the depth is shallower.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com