Production method of thin-walled low-smoke halogen-free dry loose tube

A production method and technology of loose tubes, applied in the direction of light guide, optics, instruments, etc., can solve the problems of uneven wall thickness of loose tubes, difficult control of excess length, inconsistent excess length, etc., and facilitate large-scale popularization and application , ingenious design, uniform and balanced discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

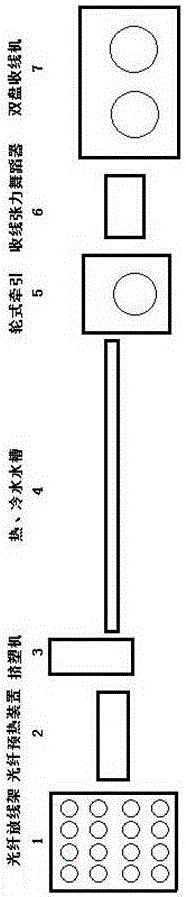

[0025] Embodiment 1: a kind of production method of thin-walled low-smoke halogen-free dry-type loose tube, described method comprises the following steps:

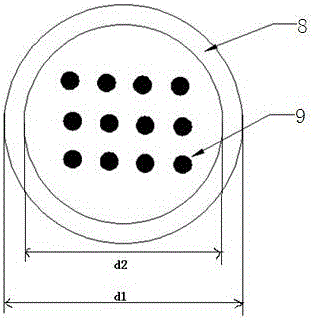

[0026] 1) Adjust the pay-off rack, that is, adjust the 1-16 optical fiber pay-off rack 1, place the 1-16 colored optical fibers 9 on the shafts of each pay-off rack, fix them, and adjust the position of the optical fibers so that 1-16 The optical fiber can be aligned with the center of the optical fiber collection mode; set the tension value of 1-16 optical fibers on the touch screen of the pay-off tension control device to 0.5N;

[0027]2) Adjust the extruder 3, pour low-smoke and halogen-free materials into the hopper, and set the temperature of the extruder. The extruder 3 is composed of a body and a head. The body is divided into 3 sections for heating. Stage heating, 5 stages of heating in total, the heating temperature is set to 140°C, 160°C, 165°C, 170°C, 178°C respectively; prepare optical fiber collection mode, o...

Embodiment 2

[0035] Embodiment 2: As an improvement of the present invention, the specific operation of the hot and cold water tanks in the step 3) is as follows, the total length of the hot and cold water tanks is 16 meters, wherein the hot water tank is 4 meters, the cold water tank is 12 meters, and the water tank is filled with water. The casing is immersed in water to cool down and crystallize the casing. The hot water tank is close to the head of the extruder, and the heating temperature of the hot water tank is set at 60-65°C, because the low-smoke and halogen-free material The best crystallization temperature is 60°C-70°C. At this temperature, low-smoke and halogen-free can crystallize well and reduce the shrinkage of the casing. The water temperature of the cold water tank is normal temperature, 18-22°C. In this way, there is a temperature difference when the casing passes between the hot water tank and the cold water tank, which is easy for the secondary crystallization of low-sm...

Embodiment 3

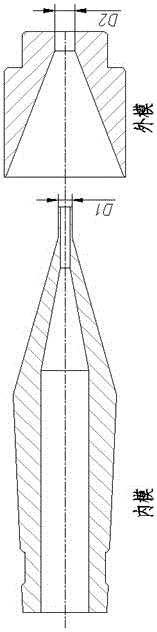

[0036] Embodiment 3: As an improvement of the present invention, a mold with a draw ratio of 2-3 is set in the head of the extruder, and the mold includes an outer mold and an inner mold, wherein the size of the outer mold is D1 , the size of the inner mold is D2, the outer diameter of the casing is d1, and the inner diameter of the casing is d2, that is, DDR (drawing ratio) = . Taking the 16-core thin-walled low-smoke halogen-free loose tube as an example, the mold size is D1=2.1mm, D2=1.6mm, and the outer diameter of the loose tube is required to be d1=1.55mm, d2=1.25mm, which is brought into the above formula, DDR=2.2, that is, the draw ratio is 2.2, such a loose tube can have a thinner wall thickness and a round appearance. This stretch ratio is beneficial to the forming of loose tube, and the pressure is small, which is easy to form a thin-walled sheath; by changing the angle of the gap between the inner mold and the outer mold, it is close to the parallel angle, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com