Low-pressure hot-melting and injection-molding assembly process for polymer lithium ion battery

A lithium-ion battery and assembly process technology, applied in battery pack parts, non-aqueous electrolyte batteries, electrolyte battery manufacturing and other directions, can solve problems such as large dimensional tolerance, battery overflow, irregular shape, etc., to improve the appearance rate of good products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

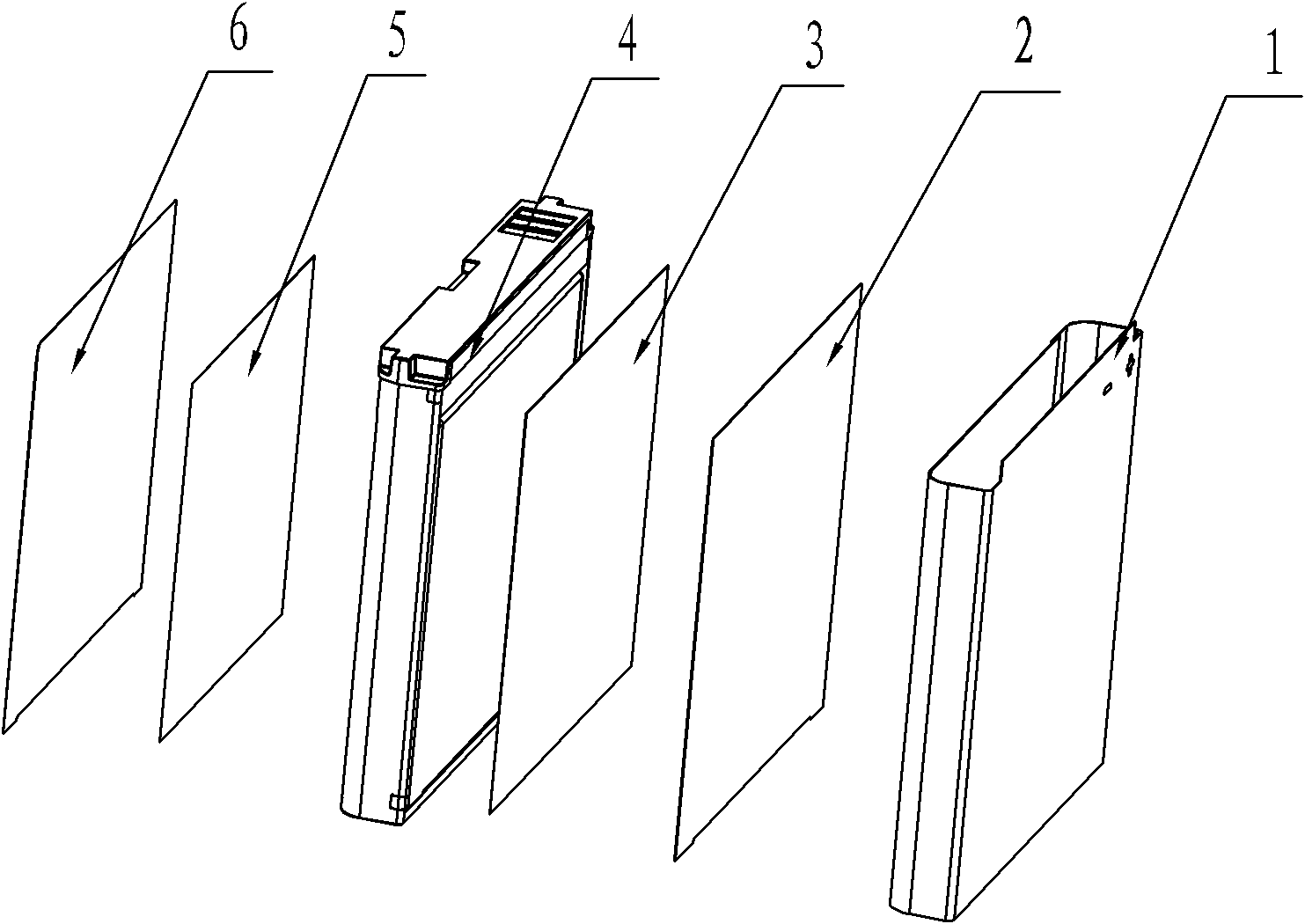

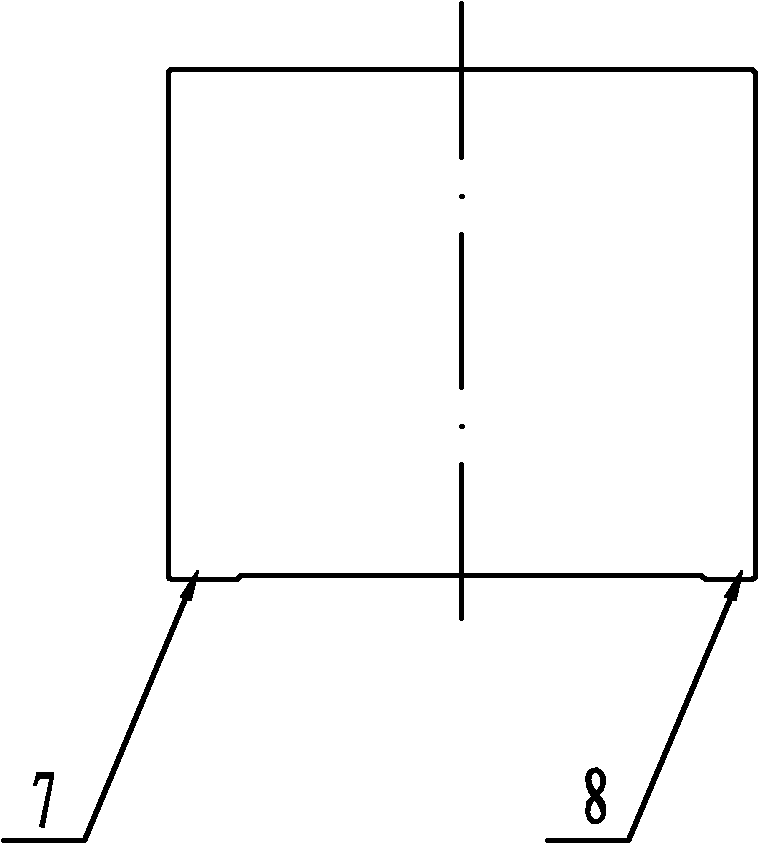

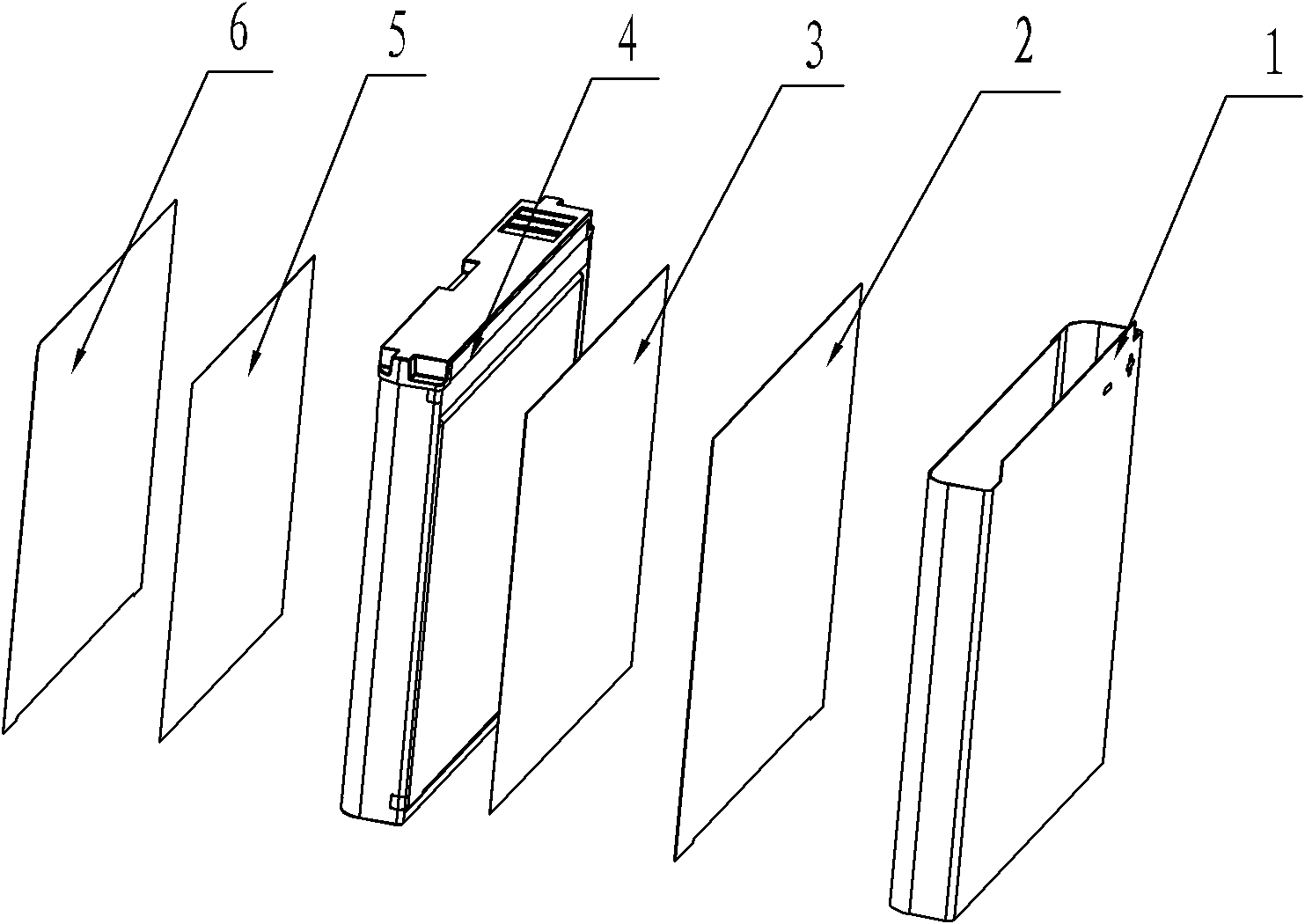

[0013] As shown in the drawings, the process of the present invention is to put the polymer lithium-ion battery cell welded with the protective plate into the plastic frame; then, perform low-pressure hot-melt injection molding on it to form the polymer lithium-ion battery semi-finished product 4; The upper and lower surfaces of the semi-finished lithium ion battery 4 are respectively pasted with stainless steel sheet 2 and stainless steel sheet 6, and the stainless steel sheet 2, stainless steel sheet 6 and the body of the semi-finished polymer lithium ion battery 4 are respectively connected with double-sided adhesive tape 3 and double-sided adhesive tape 5 ; Finally, label 1 on the outside of the stainless steel sheet. The thickness of the stainless steel sheet is 0.05mm. There are two asymmetric bottom corners on the stainless steel sheet, that is,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com