Laminated type rubber coating line card and manufacturing and fixing method

A rubber-coated wire, press-fit technology, applied in the direction of bendable lead devices, circuit/collector parts, electrical components, etc., can solve the problems of inability to install and remove, low efficiency, and high defect rate, and achieve convenient use and operation. Flexible, convenient and fast operation, good pressing force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples are further explanations and descriptions of the present invention, and do not constitute any limitation to the present invention.

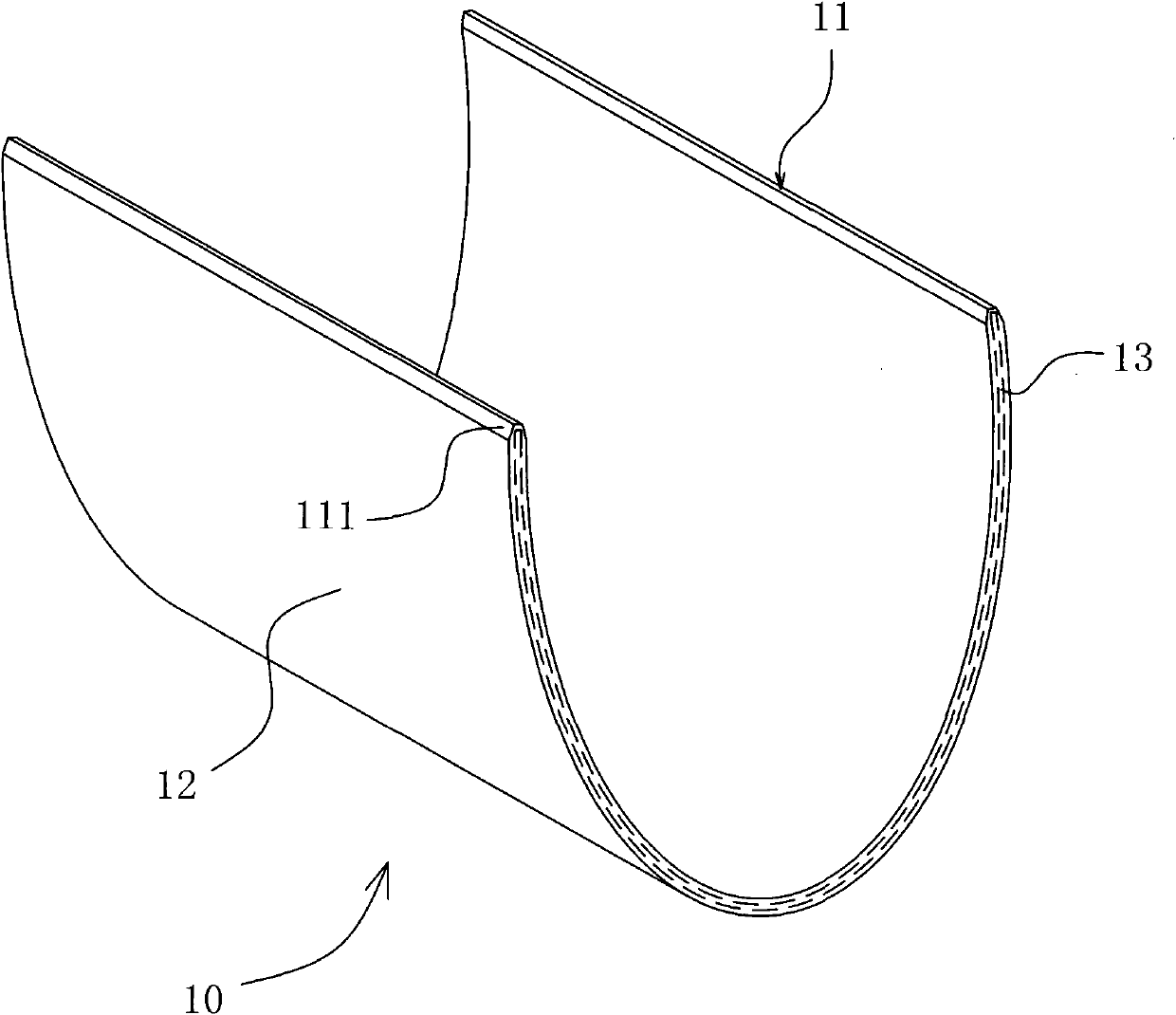

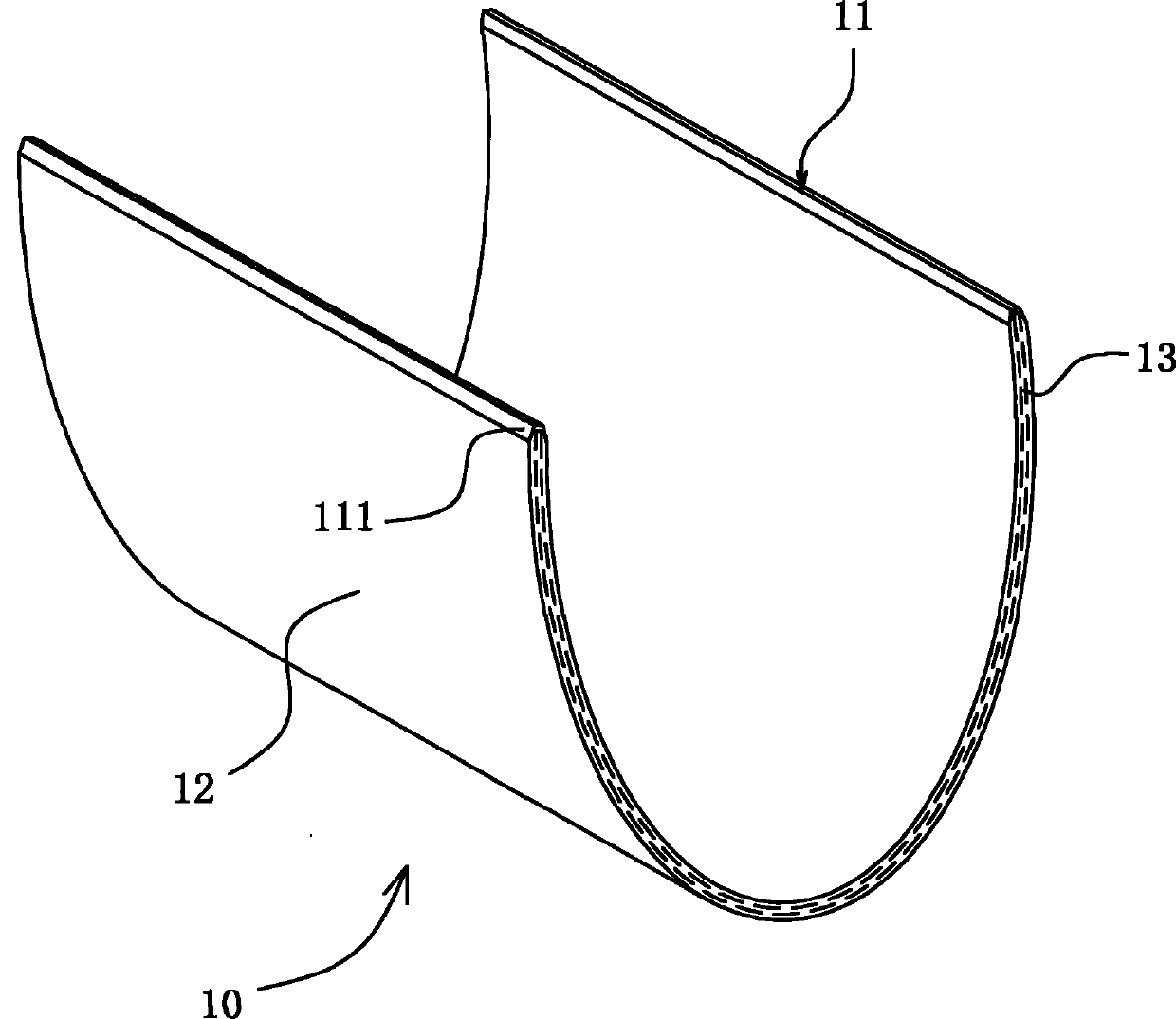

[0025] Refer to Figure 1A , Figure 1B The press-fit type rubber-covered wire card 10 of the present invention is a curved semicircular or arc-shaped sheet-shaped body, and both ends of the length direction thereof form an open end 11. The line card is stamped from a rectangular metal sheet 13, and its length and width can be determined according to the number of wires (bundles) and cables (bundles) to be fixed and the wire diameter. In order to make the open end of the line card fit tightly during pressing, a symmetrical tapered or trapezoidal slope 111 is provided on the edge of the open end of the rubber-coated line card. In order to avoid scratching the fixed wires and cables and their insulation, and to form an integrated effect with the wires, cables, and braided sleeves or open braided sleeves covering the wires ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com