Method and device for modulating electromagnetic stirring and rotating magnetic field based on permanent magnet

A technology of electromagnetic stirring and rotating magnetic field, which is applied in the direction of stirring devices, chemical instruments and methods, mixers, etc., can solve problems such as white and bright bands, influence, slab segregation, etc., and achieve intuitive changes, strong operability, and increase productivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

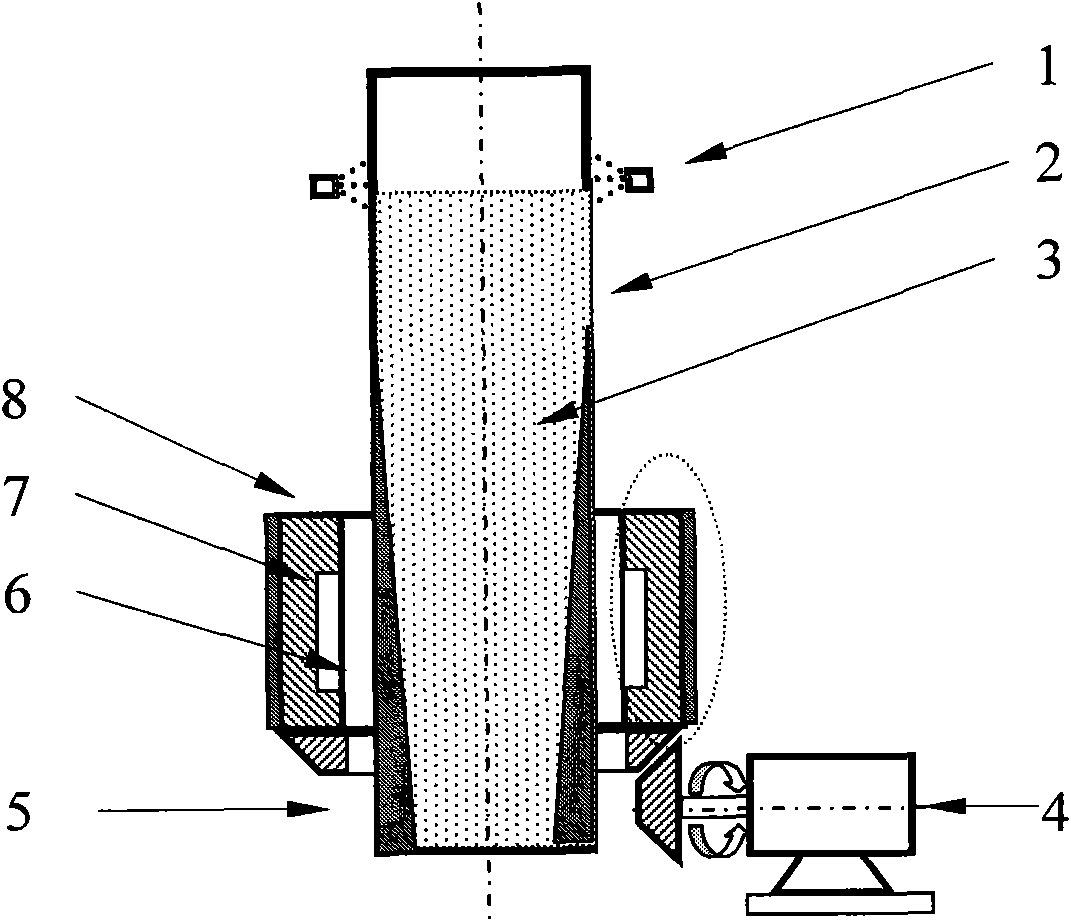

[0017] Embodiment one: see figure 1 , this electromagnetic stirring and electromagnetic stirring rotating magnetic field modulation method based on permanent magnets can generate magnetic induction according to the equation B=B 0 Cos(2πωt+φ) changing magnetic field, where the magnetic field amplitude B 0 The three parameters , magnetic field frequency ω and magnetic field phase φ can be modulated individually or jointly. The stirrer 8 is connected with the programmable stepper motor 4, and the two always keep the same rotation mode, the amplitude B 0 , frequency ω and phase φ modulation are as follows:

[0018] ① adjust the rotational speed of the stepper motor 4 to achieve the purpose of adjusting the magnetic field frequency ω;

[0019] ② Change the direction of rotation of the stepper motor 4 to achieve the purpose of adjusting the magnetic field phase φ;

[0020] ③ By inlaying permanent magnets 6 of different materials, or changing the arrangement of permanent magnets ...

Embodiment 2

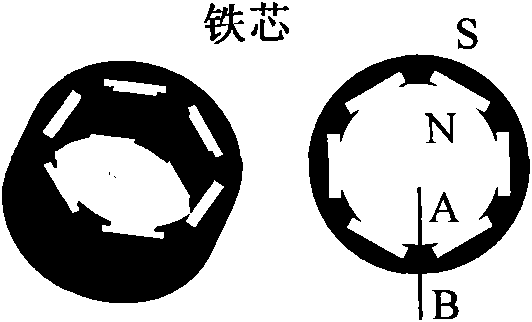

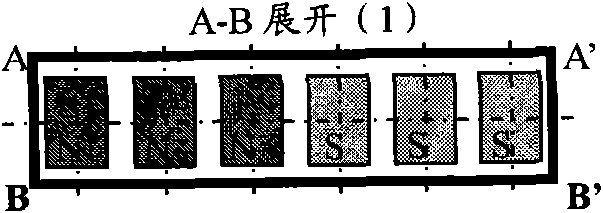

[0021] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the special features are as follows: the variation range of the magnetic field frequency ω is 0-100000 Hz; the range of the magnetic field phase φ is 0-360°; the material of the permanent magnet 6 It is one or more of oxide magnets, alloy magnets, neodymium-iron-stilbene magnets, samarium-cobalt magnets, rubber magnets, and plastic magnets. The permanent magnets 6 are arranged in such a way that S poles and N poles are symmetrically distributed on two half circles; The poles and the N poles are alternately arranged in the circumferential direction; the S poles and the N poles are evenly arranged in the axial direction of the two semicircles, one or more of these three arrangements, see image 3 , Figure 4 and Figure 5 .

Embodiment 3

[0022] Embodiment 3: An electromagnetic stirring device based on permanent magnets, using the above-mentioned modulation method to adjust the magnetic field, including an electromagnetic stirrer 8 wrapped outside the crystallizer, the structure of the stirrer 8 is: a plurality of permanent magnets 6 are embedded in a ring In the iron core 7, the annular iron core 7 is connected to the programmable stepping motor 4 through the transmission gear 5, and the annular iron core 7 is driven by the stepping motor 4 to rotate, and the magnetic field of the agitator 8 and the stepping motor 4 are always Keep the rotation the same way.

[0023] working principle

[0024] The stirrer 8 is wrapped around the outer edge of the crystallizer 2, and the generated magnetic field acts on the inner molten metal 3 through the mold 2. The magnetic field changes according to certain rules, and an induced current will be generated in the molten metal 3. Combined with the rotation of the magnetic fiel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com